The Chinese government attaches great importance to the protection of the atmospheric ozone layer. According to the “Vienna Convention for the Protection of the Ozone Layer” formulated by the United Nations, the “Montreal Protocol on Substances that Deplete the Ozone Layer” and “< The three documents of the Kigali Amendment to the Montreal Protocol on Substances that Deplete the Ozone Layer, the Chinese government approved the implementation of the Phase-out of Substances that Deplete the Ozone Layer in China in January 1993 National Program” (hereinafter referred to as the “National Program”).

According to the requirements of the “National Plan”, the polyurethane foam industry has formulated a gradual replacement plan for the replacement of blowing agents. Since the early 1990s, foaming The substitution work of HCFC-141b has been continuously promoted. The first generation of CFC-11 has been banned, and the second generation of HCFC-141b will also be banned in 2026.

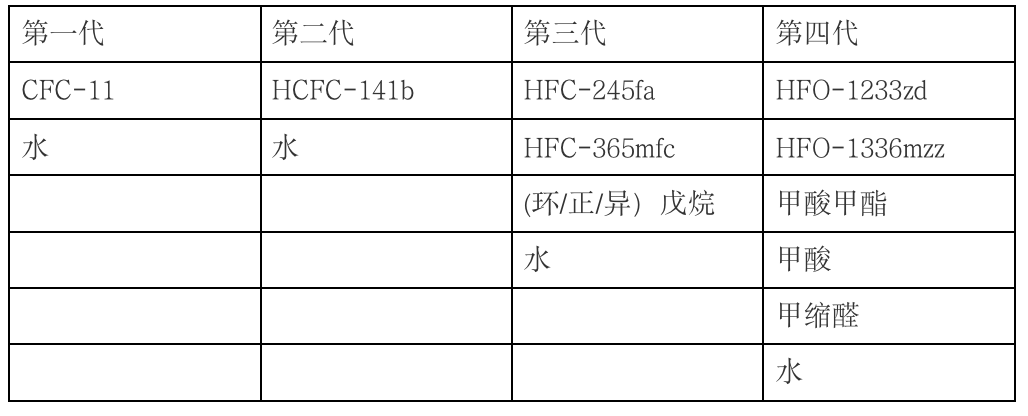

Table 1: Foaming agent classification

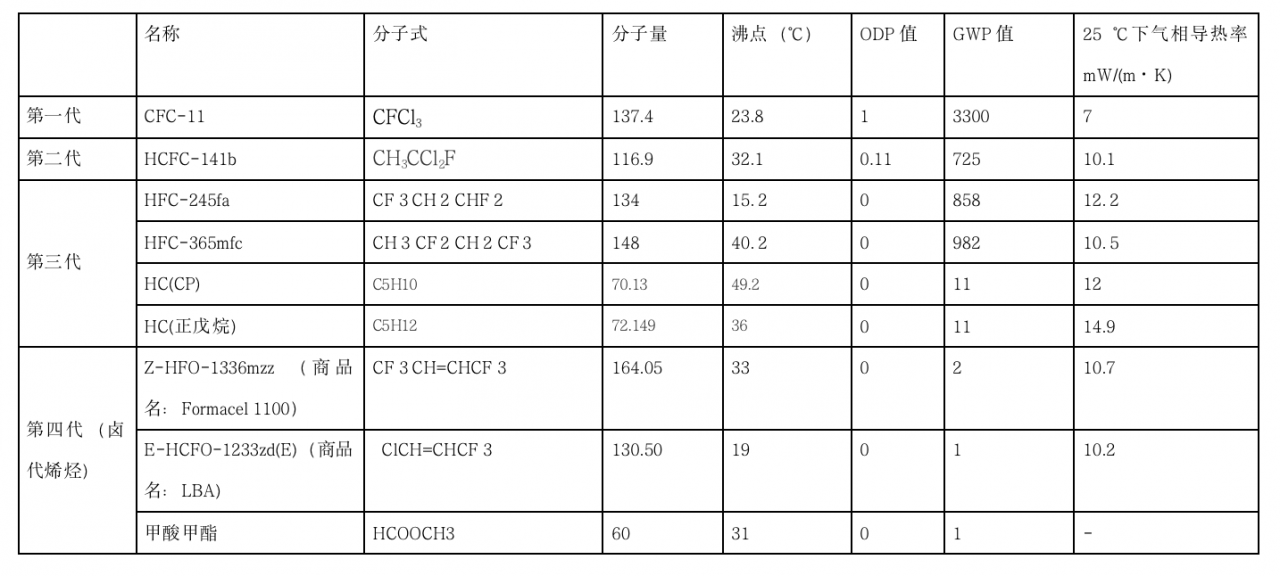

Table 2: Some physical performance indicators of the first to fourth generation foaming agents

foaming Development status of agent

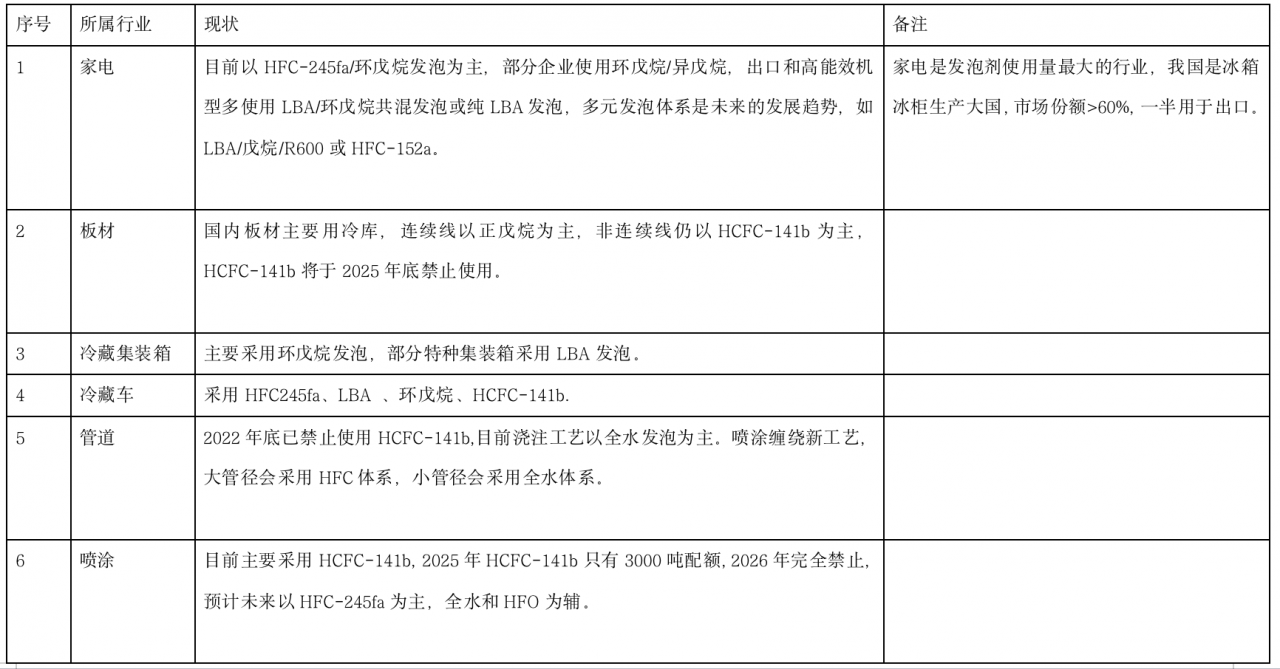

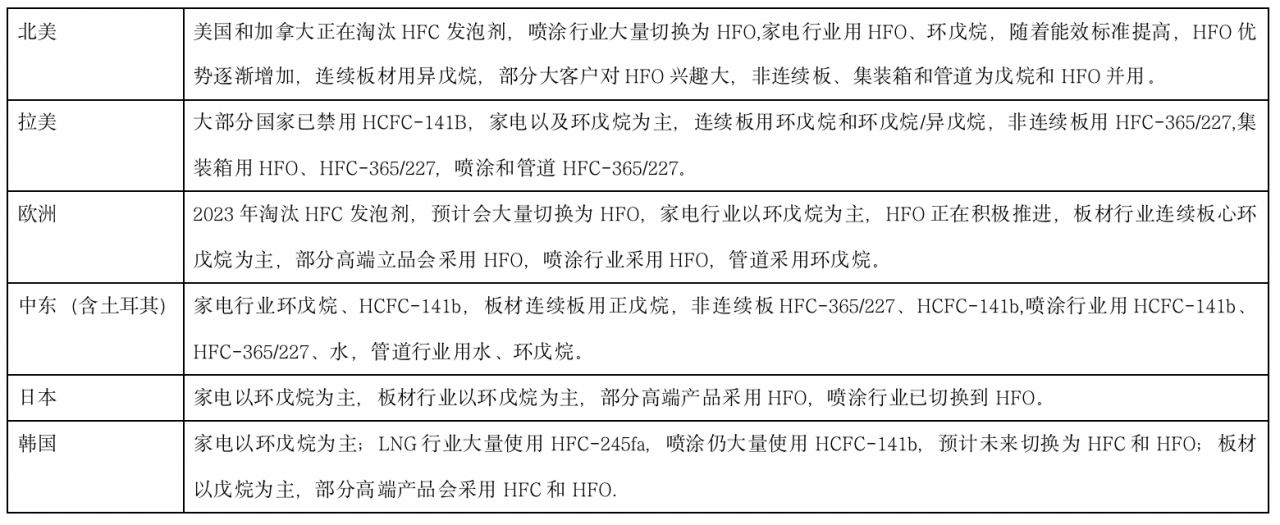

Most polyurethane foaming agents are used in The field of rigid foam mainly includes home appliances, refrigerated containers, refrigerated trucks, plates, pipes, spraying industries, etc. Table 3 and Table 4 list the application status of domestic foaming agents and foreign foaming agents in detail.

Table 3: Domestic polyurethane Current situation of blowing agent for rigid foam

Table 4: Foreign release Application Status of Foaming Agent

foaming The future development trend of agents

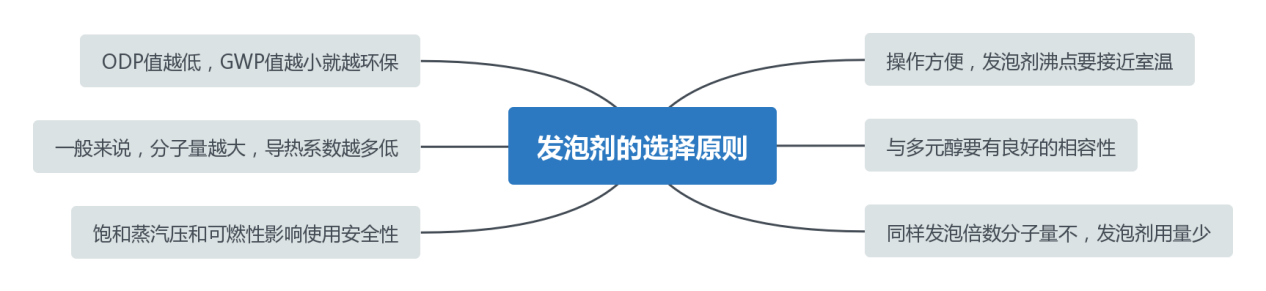

The future development trend of polyurethane foaming machine It is determined according to the selection principle of the blowing agent. The following figure shows the factors to be considered when choosing a blowing agent:

As the country phases out HCFC-141b process The speeding up and coming to an end, the rigid polyurethane foam industry is in urgent need of a new generation of environmentally friendly foaming agents. Given that the third generation contains��The blowing agent HFC has not yet been used on a large scale in China, and is restricted by the Kigali Amendment. The domestic polyurethane foam industry may step over the HFC blowing agent and directly transition to the fourth-generation fluorine-containing blowing agent HFO- 1336mzz (Z) and HCFO-1233zd (E). From the evaluation results, the fourth-generation foaming agent is suitable for almost all polyurethane rigid foam applications, including home appliances, panels, spraying, and cast-in-place. Although it has not yet been fully industrialized and the cost is high, with the further reduction of HCFC-141b production capacity and the pressure of environmental protection policies, as well as the progress of the fourth-generation fluorine-containing blowing agent production process and cost reduction, future parts require higher insulation performance The fields that cannot be converted to pentane foaming will be the important application fields of the fourth generation of fluorine-containing blowing agents. However, after the elimination of HCFC141b in China, cyclopentane and cyclopentane/isopentane systems may be used in refrigerators and freezers for a long time because their prices are relatively low, and products using HFO systems will mainly be exported to developed countries and regions; according to Tiantian Chemical The website predicts that cyclopentane and cyclo/isopentane systems will be used in the plate field; water will be mainly used in the pipeline field, and cyclopentane and isopentane will be mixed in a small amount.

Source of content: Exclusive release by Tiantian Chemical Network

微信扫一扫打赏

微信扫一扫打赏