With the rapid development of new energy vehicles, its supporting industries are also rising rapidly. The intelligent upgrade of car lights has brought the application of penetrating lights and ambient lights, and the styling design is also flourishing with different styles. While satisfying the basic lighting functions, it began to take into account the functions of creating atmosphere and achieving enhanced car recognition. Therefore, many car lighting manufacturers will add light guide strips to the headlights, taillights and ambient lights to form personalized visual lighting effects. It not only improves the appearance of the vehicle, but also improves the recognition of the vehicle. The demand for light guide strips from auto lamp manufacturers is gradually increasing.

At present, there are more and more through-type tail lights in the application of light guide strips, and the demand for length is getting longer and thicker. However, thick-walled plastic parts are prone to problems such as sink marks, shrinkage cavities, depressions, air bubbles, and under-injection during the injection molding process; secondly, the shape of the through-type taillight light guide is complex, and most of them are shaped like long strips, which is very difficult to form . This brings new and huge challenges to the injection molding process, parameter setting and mold design of the light guide strip, especially the injection molding process is the most critical.

Car lamp manufacturers need to choose reliable injection molding machines to produce high-quality light guide strips. There are higher requirements for the plasticizing ability, low-speed injection stability, pressure control accuracy and overall rigidity of the injection molding machine. However, the injection molding machines produced by general injection molding machine manufacturers cannot produce high-quality injection molding machines in terms of core technology or equipment stability. Light guide strips that meet customer requirements.

As a leading brand in the injection molding machine industry with 65 years of experience in injection molding, Chen Hsong has been providing one-stop injection molding solutions for cooperative customers, and is the best partner for automotive lighting manufacturers. For the injection molding of automotive light guide strips, Chen Hsong has a complete set of professional solutions.

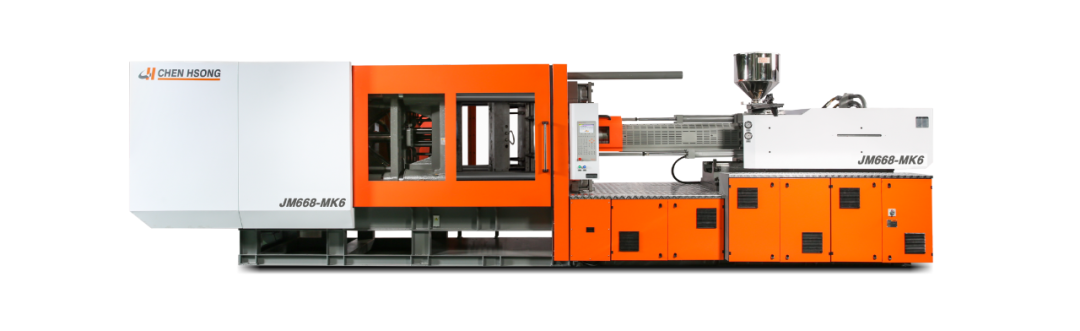

For thick-walled and long light guide strips, Chen Hsong servo-driven injection molding machine MK6 series, all-electric injection molding machine SPARK series and two-platen injection molding machine TP Smart

The series has the following characteristics beyond the peers, which can perfectly meet the stringent requirements in the injection molding of light guide strips.

1. The special plasticizing screw can effectively improve the plasticizing ability to meet the injection molding requirements of the light guide strip;

2. Low-speed injection stability, to achieve 0.1mm/s injection speed control;

3. The pressure control precision is high, ensuring the pressure control precision of 0.5 bar;

4. The overall rigidity of the equipment is high, and the deformation is small during high-pressure injection molding, which ensures the molding accuracy of the thick-walled light guide strip;

5. Multi-mode compression injection molding technology can effectively reduce the internal stress of thick-walled products and improve the permeability of optical products.

▲Chen Hsong servo drive injection molding machine MK6 series

▲SPARK series of Chen Hsong all-electric injection molding machines

▲Chen Hsong two-platen injection molding machine TP Smart series

Currently, Chen Hsong servo-driven injection molding machine MK6 series, all-electric injection molding machine SPARK series and two-platen injection molding machine TP Smart

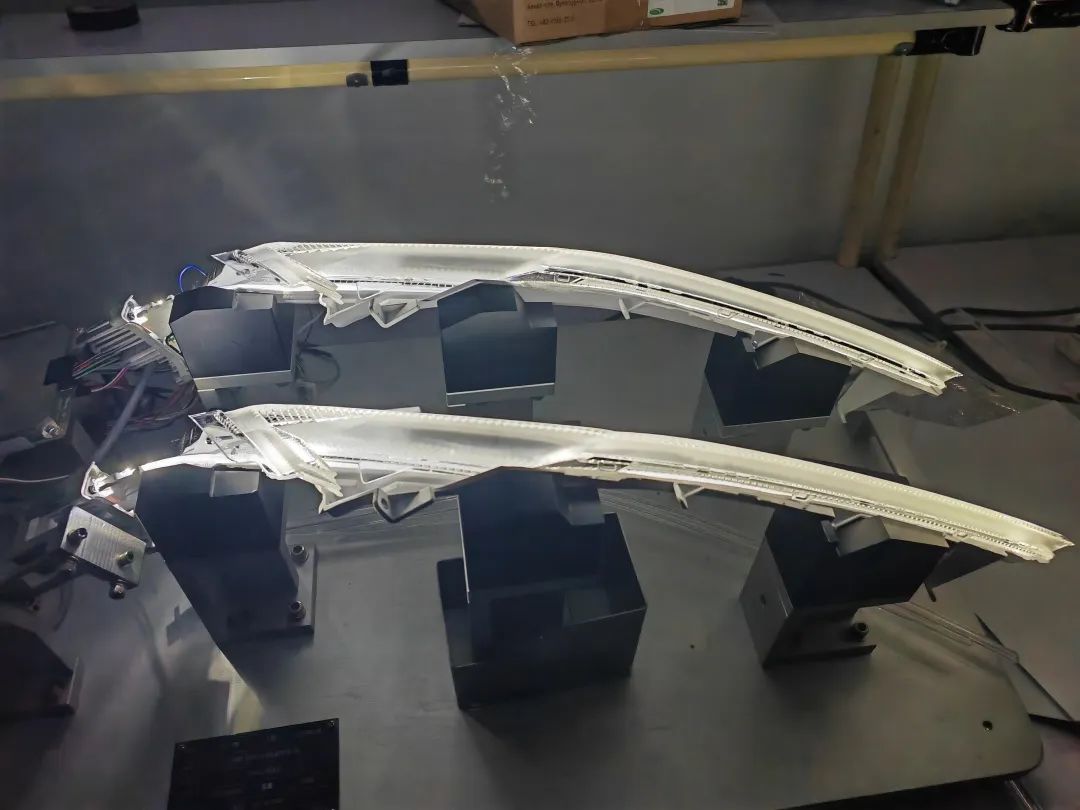

The series has been maturely applied to many well-known auto parts manufacturers, including well-known car lamp manufacturers, who use Chen Hsong’s JM668-MK6 to make short light guide strips and long light guide strips

, light guide thick-walled cover and other products, the yield and consistency of both exceeded 99%. The light guide effect and quality have passed the recognition of its downstream well-known new energy car companies, and the customer feedback is good.

▲Chen Hsong produced light guide strips for cooperative customers

In the future, Chen Hsong will continue to increase investment in R&D and equipment, gain an in-depth understanding of the needs of new energy vehicle customers, and develop more targeted injection molding solutions to meet customers’ growing stringent injection molding needs

微信扫一扫打赏

微信扫一扫打赏