On April 27, 2023, Ningbo Changhong Polymer Technology Co., Ltd. (abbreviation: Changhong High-Tech) released its 2022 annual report.

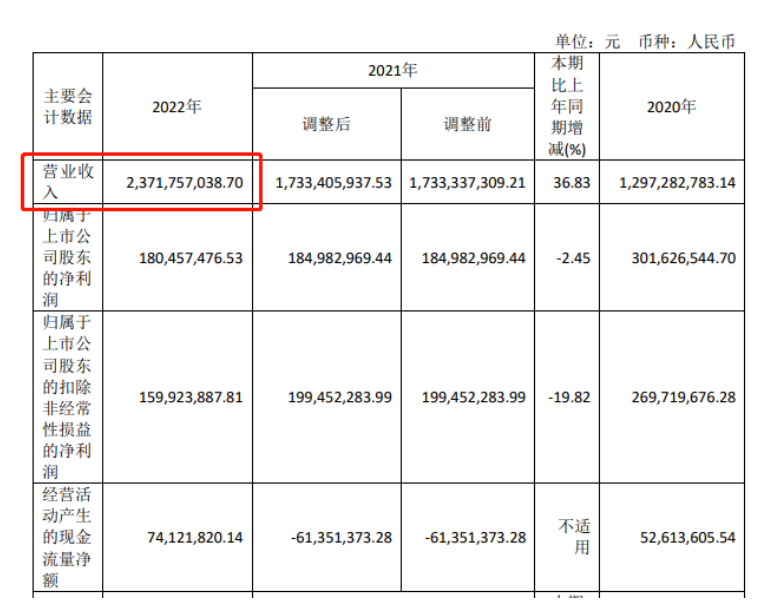

The annual report shows that Changhong Hi-Tech continued to maintain a high market share, achieving operating income of 2.372 billion yuan, a year-on-year increase of 36.83%; affected by the sharp rise in short-term raw material prices, the company realized a net profit of 180 million yuan attributable to the parent, a slight decrease of 2.45% year-on-year. In the future, with the economic recovery and continuous expansion of production capacity, the company’s profitability is expected to recover rapidly.

BDO-PBAT-modified PBAT-degradable products

In 2020, in order to comply with the general trend of “dual carbon” and solve the problem of white pollution, the company decided to invest in the construction of a 600,000-ton/year fully biodegradable thermoplastic industrial park PBAT/PBS/PBT flexible and flexible production project. The scale ranks in the forefront of the country. Currently The first phase of 120,000 tons/year project has been completed and put into operation.

During the reporting period, the company made a strategic plan, planning to invest in the construction of a natural gas deep processing project in Qingyang, Gansu to produce BDO, and to invest in the construction of a calcium carbonate degradable masterbatch project in Hezhou, Guangxi, so as to open up an industrial layout that integrates the upstream and downstream of degradable plastics. , running through the industrial chain from BDO to PBAT and PBT products; PBAT and PBT modification to degradable products.

With the gradual implementation of the above-mentioned projects, the company’s scale and production capacity will grow rapidly, the industrial chain will become more complete, the upstream and downstream integration capabilities around the industry will be further strengthened, the company’s comprehensive cost will drop significantly, and the scale benefits will gradually become prominent. At present, the land required for the Hezhou project in Guangxi has been successfully delisted and has officially entered the construction stage.

At the same time, relying on the strong research and development capabilities of the Chinese Academy of Sciences, the subsidiary Changhong Biology has obtained the exclusive authorization to use its patents in Zhejiang Province. In the future, with the gradual maturity of technology, we will gain R&D advantages in the PBAT industry.

In addition to the production of PBAT and PBT raw materials, Changhong Biology also plans to produce modified PBAT raw materials, biodegradable films, biodegradable plastic bags, disposable biodegradable tableware and other end products, completing the company’s entire industrial chain layout.

Since 2021, the price of BDO has fluctuated violently, and the sharp fluctuations in raw material prices may bring the risk of rising costs to the company. Although the company is already planning the production of BDO, it still needs to purchase externally in the short term.

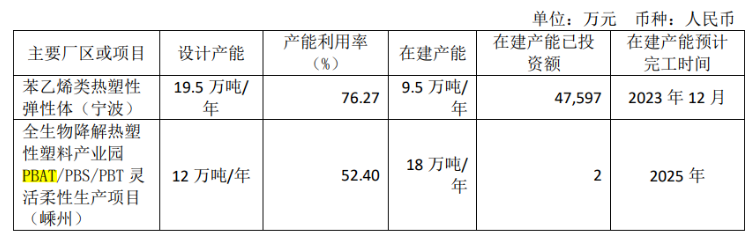

According to the annual report data, the capacity utilization rate of the 120,000-ton/year fully biodegradable thermoplastic industrial park PBAT/PBS/PBT flexible production project (Shengzhou) is 52.40%. In addition, the company still has 180,000 tons/year of production capacity under construction, and the expected completion time is 2025.

Summary of the progress of the three major projects

(1) 600,000 tons/year fully biodegradable thermoplastic industrial park PBAT/PBS/PBT flexible flexible production project

On October 27, 2020, the company’s second extraordinary shareholders’ meeting in 2020 reviewed and approved the “Proposal on Investing in the Construction of a 600,000-ton/year Fully Biodegradable Thermoplastic Industrial Park PBAT/PBS/PBT Flexible and Flexible Production Project”. The second phase is carried out, each phase is 300,000 tons per year, and the total construction period is 5 years. In the first phase, a 120,000-ton/year production line will be built for the first time, which can flexibly produce different products such as PBAT, PBS, and PBT according to market demand. At the same time, it has the ability to extend the chain and modify the production of other products of different brands. At the same time, it is equipped with downstream films, plastic bags, etc. Terminal finished product production, storage and transportation facilities. At present, the first phase of the first project has been running smoothly.

(2) Qingyang Natural Gas Deep Processing Project

On September 30, 2022, the company’s 20th meeting of the second session of the board of directors in 2022 reviewed and approved the “Proposal on Signing the and Foreign Investment to Establish a Wholly-owned Sun Company”. The annual output of the project is 60 10,000 tons of BDO (1,4-butanediol), 300,000 tons of PBAT projects. The project construction includes 4×50,000 tons/year acetylene unit, 6×240,000 tons/year formaldehyde unit, 4×150,000 tons/year BDO unit, 2×150,000 tons/year PBAT unit and supporting public and auxiliary facilities. The company intends to use scattered natural gas as raw material to produce BDO products and produce PBAT or PBT products by alkyne aldehyde method. At present, the first phase of the project has not yet been invested.

(3) Changhong Biodegradable Masterbatch Industrial Park Project

On December 14, 2022, the twenty-second meeting of the second session of the board of directors of the company reviewed and approved the “Proposal on Signing the and Foreign Investment to Establish a Wholly-owned Sun Company”. The production land of the project is planned once and constructed in two phases. The first phase is to build a high-end modified calcium carbonate production line with an annual output of 500,000 tons/year, a degradable masterbatch production line with an annual output of 300,000 tons, and a shoe material masterbatch production line with an annual output of 300,000 tons. The second phase of construction has an annual output of 500,000 tons/high-end transformation��Calcium carbonate production line, 300,000 tons/year degradable masterbatch production line, 300,000 tons/year shoe material masterbatch production line, 100,000 tons/year degradable products and agricultural mulch film, corresponding supporting warehouse, power, office and other facilities. At present, the construction of the first phase is progressing steadily.

微信扫一扫打赏

微信扫一扫打赏