The latest scientific research news about epoxy resin came from the Swiss Federal Laboratory for Materials Science and Technology (Empa). In addition to completing the flame retardant function and mechanical strength enhancement technology of epoxy resin, the laboratory also It also develops the repairability of epoxy resin and realizes the recyclable recycling of epoxy resin.

As the main resin of coatings, epoxy resin is used in industrial coatings and automotive coatings because it has better heat resistance than latex paints and alkyd paints.

Epoxy resins are tough and versatile polymer materials. They are used in combination with glass or carbon fibers, for example to make parts for planes, cars, trains, ships and wind turbines. Fiber-reinforced epoxy polymer materials have excellent mechanical and thermal properties and are much lighter than metals. However, their weakness is that they are not recyclable, and there is no recyclable epoxy resin material in the current position.

However, now by Sabyasachi of Empa Advanced Fiber Laboratories

Led by Gaan, the Empa researchers developed an epoxy-based polymer material. The material is fully recyclable, repairable and flame retardant, while maintaining the good thermomechanical properties of epoxy resins. They published the research results in the “Journal of Chemical Engineering”.

Recycling epoxy resin is no easy task because epoxy resin is a thermoset polymer, and with this type of polymer, the polymer chains are tightly cross-linked, and these chemical cross-links make melting impossible. Once the material hardens, it cannot be reshaped.

This is not the case for thermoplastic polymers such as PET or polyolefins. Their polymer chains are in close proximity but are not chemically linked to each other. When heated, these polymers can melt and form new shapes. However, their mechanical properties at high temperatures are generally inferior to thermosets due to the lack of crosslinking.

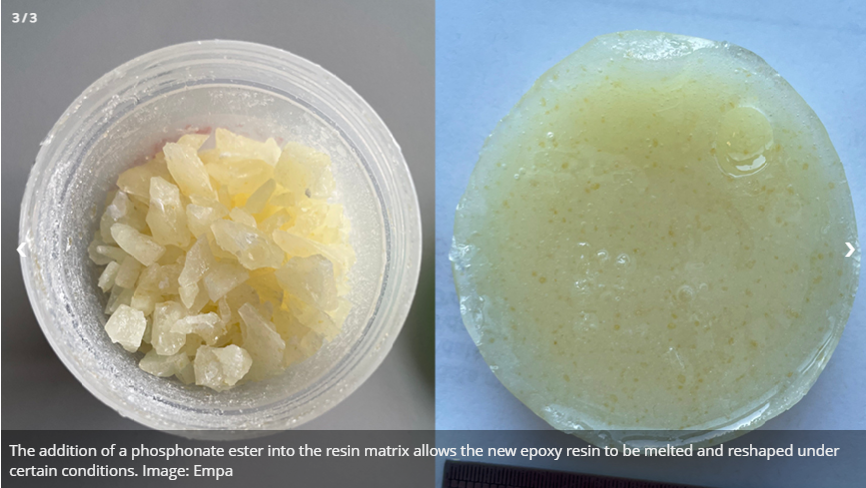

Empa’s unique epoxy resin, developed in collaboration with international partners, is technically a thermoset polymer, but unlike other thermoset resins, it can be reshaped like a thermoplastic polymer. The key is to add a very specific functional molecule in the phosphonate class to the new resin matrix. “We originally synthesized this molecule as a flame retardant,” said Empa scientist Wenyu, co-inventor of the technology.

Wu Klingler said. However, the bonds that the molecules form with the epoxy’s polymer chains are dynamic and can break under certain conditions. This loosens the crosslinks of the polymer chains, allowing them to be melted and reshaped.

The material, also known as vitrified polymers, has been around for about a decade and is considered particularly promising. “Today, fiber-reinforced composites are not recyclable at all, except under very harsh conditions, which would damage the recycled fibers,” said Wenyu

Wu Klingler explained. “Once they reach the end of their useful life, they are either incinerated or disposed of in landfill. With this technology, it will be possible for them to re-enter circulation for the first time.”

“Our vision for the future,” said panel leader Sabyasachi

Gaan added, “is a composite material in which both the fibers and the resin matrix can be completely separated and reused.” Manufacture of bicycles, etc. “The production of carbon fiber requires a lot of energy and releases a lot of carbon dioxide,” he explained. “If we could recycle them, they would have a much better environmental footprint and be much less expensive.” Also, it would be possible to recycle valuable elements such as phosphorus attached to the base polymer, such as epoxy resin.

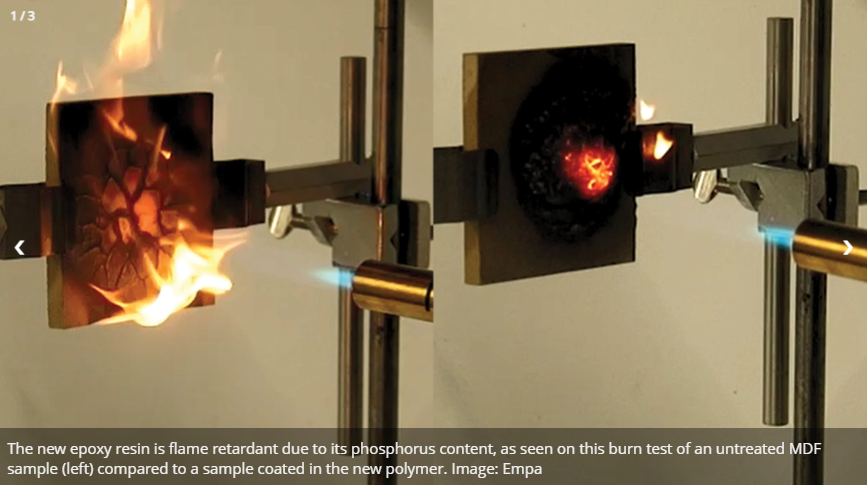

The new epoxy resin is flame retardant due to its phosphorus content, as shown in a burn test of an untreated MDF sample (left) compared to a sample coated with the new polymer

Repair is usually impossible with thermoset materials, but cuts in the new epoxy can be repaired with heat and pressure

Adding a phosphonate to the resin matrix allows the new epoxy to melt and reshape under certain conditions

Fiber-reinforced composites are not the only application for this new polymer. For example, it can be used to produce epoxy coatings for wood floors as a clear, corrosion-resistant coating that is also flame-retardant and can “heal” scratches and dents with a small amount of pressure and heat.

Gaan explained: “Instead of developing a material for a specific use, we have opened up a functional toolbox. Flame retardancy, recyclability, and repairability are given. We can optimize all other properties based on the intended use. For example, he said, flow characteristics are particularly important for the production of fiber-reinforced high epoxies, while outdoor wood coatings should be weather-resistant, and the new epoxy resins can all be custom implemented.

To pursue these and other applications of this material, the researchers are now looking for industrial partners. Empa sees a commercial opportunity for the material, which, in addition to all its other favorable properties, is cheap and easy to manufacture.

微信扫一扫打赏

微信扫一扫打赏