Background and overview[1]

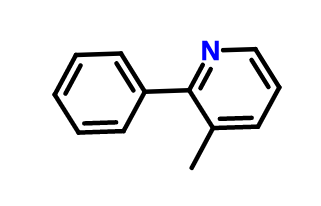

2-Phenylpyridine compound 3-methyl-2-phenylpyridine is not only an important structural component of medicines, pesticides, dyes, functional materials, spices and natural products, but also an important intermediate in organic synthesis.

Preparation[1-2]

Method 1. Under nitrogen atmosphere, add 5-methyl-2-pyridine fluorosulfonate (382.3 mg, 2.0 mmol) and nickel bromide (14.6 mg, 0.067 mmol) into a 15 mL dry and clean Schlenk tube. , triphenylphosphine (35.2 mg, 0.067 mmol), tetrahydrofuran (2.0 mL) and phenylzinc chloride in tetrahydrofuran (14.4 mL, 0.42 mol/L, 6.0 mmol). Then, the Schlenk tube was placed in a 60°C oil bath for heating and reaction for 6 hours. At this time, TLC showed that the raw material reaction was complete. Then, the Schlenk tube was placed in an ice-water bath to cool, and 2.0 mL of purified water was added to the reaction system to quench the reaction. After stirring at room temperature for 15 minutes, the mixture was allowed to stand and separated to obtain an aqueous phase and an organic phase. After the aqueous phase was extracted with ethyl acetate (3 mL×3), the extracted phase was combined with the aforementioned organic phase, dried over anhydrous sodium sulfate, and then filtered to obtain a filtrate. After the filtrate was concentrated, 307 mg of the oily liquid product 3-methyl-2-phenylpyridine was finally obtained through silica gel column chromatography, with a yield of 91%. The nuclear magnetic spectrum of the obtained product is as follows: 1HNMR (500MHz, CDCl3) δ = 8.53 (d, J = 4.5Hz, 1H), 7.58 (d, J = 7.6Hz, 1H), 7.55-7.48 (m, 2H), 7.45 (dd, J=10.9, 3.7Hz, 2H), 7.42-7.35 (m, 1H), 7.18 (dd, J=6.4, 5.0Hz, 1H ), 2.36(s, 3H)

Method 2: Weigh 3-methylpyridine-2-carboxylic acid (36.9mg, 0.3mmol) and potassium phosphate (127.4mg, 0.6mmol), and add benzene (1mL) and tert-butyl hypochlorite ( 68 μL, 0.6 mmol) into a 25 mL Schlenk reaction bottle, and then placed in an 80°C oil bath for reaction for 8 hours. After the reaction, the solvent was removed under reduced pressure, petroleum ether/ethyl acetate was used as the eluent, and the reaction was separated on a silica gel column. The yield of 3-methyl-2-phenylpyridine was 71%. 1HNMR (400MHz, CDCl3): δ8.53 (dd, J=4.7, 1.1Hz, 1H), 7.57 (dd, J=7.7, 0.9Hz, 1H), 7.53-7.49(m, 2H), 7.47-7.34(m, 3H), 7.17(dd, J=7.7, 4.8Hz, 1H), 2.34(s, 3H); 13 CNMR (100MHz, CDCl3): δ158.7, 147.0, 140.6, 138.5, 130.8, 128.9, 128.1, 127.9, 122.1, 20.0.

References

[1] Preparation method of CN201710014409.2 biaryl compound

[2]CN201610942701.6 A synthesis method of 2?phenylpyridine compounds without transition metal catalysis

微信扫一扫打赏

微信扫一扫打赏