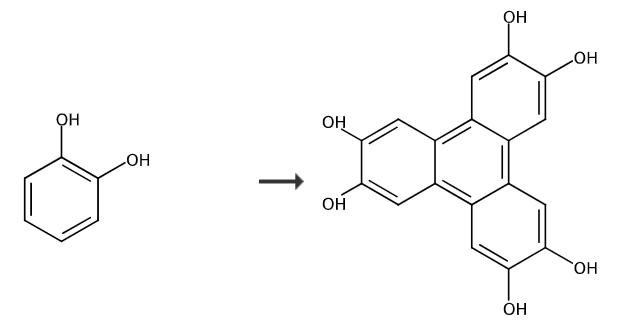

Background and overview[1-2]

2,3,6,7,10,11-Hexahydroxytriphenyl, referred to as HHHP, can be prepared from catechol in one step. There are reports in the literature that 2,3,6,7,10,11-hexahydroxytriphenyl can be used to prepare metal organic frameworks (MOFs). Metal-organic frameworks are a type of material formed by coordination between metal ions and organic ligands. Compared with traditional inorganic porous materials, MOFs have higher porosity, larger specific surface area, adjustable pore structure and excellent structural stability, and are widely used in the field of chemical energy storage.

Preparation[1]

Catechol (20g, 0.182mol) and hexahydrate/ferric (III) chloride (196.8g, 0.728mol) were reacted using ultrasound for 24 hours. After the reaction is completed, the mixture is washed with dilute hydrochloric acid and water, and extracted with heated cyclopentanone to obtain 2,3,6,7,10,11-hexahydroxytriphenyl. 1H NMR (600MHz, CDCl3) δ7.82 (s, 6H), 5.35 (s, 6H)

Apply[2]

2,3,6,7,10,11-hexahydroxytriphenyl is used to prepare spherical stacked π-d conjugated Fe-HHTP. The electrode prepared based on this material has certain redox properties and electrochemistry Energy storage properties.

1. Dissolve 2,3,6,7,10,11-hexahydroxytriphenyl (12.8mg, 0.04mmol) in a mixed solution of 4mL DMF/H2O (V:V=1:1), and sonicate (120W, 53KHz) for 3 minutes to form a uniform solution;

2. Dissolve Fe(NO3)3·9H2O (16.2mg, 0.04mmol) in 12mL DMF/H 2O (V:V=1:1) mixed solution, ultrasonic (120W, 53KHz) for 5 minutes to form a uniform solution;

3. Add 12 mL of Fe(NO3)3·9H2O solution into the lining of the 25 mL reaction kettle and stir ( Six combined stirrers until vortex appears)5min;

4. Under stirring conditions, add 4 mL of 2,3,6,7,10,11-hexahydroxytriphenyl solution dropwise to the solution in step 3 (complete the dropwise addition within 3 minutes);

5. Place the reaction kettle in a blast drying oven from room temperature to 110°C, and react for 12 hours. After the reaction is completed, cool to room temperature, wash the resulting product with ethanol, and centrifuge 3 times at 12000 rpm/10 min. The obtained spherical stacked Fe-HHTP.

References

[1] From PCT Int. Appl., 2017131406, 03 Aug 2017

[2] [Chinese invention] CN201910311069.9 Preparation of π-d conjugated Fe-HHTP metal-organic frameworks with different morphologies and related electrodes

微信扫一扫打赏

微信扫一扫打赏