Background and overview[1]

3-Ethynyl anisole is an ether derivative and can be used as a pharmaceutical synthesis intermediate.

Preparation[1]

3-Ethynyl anisole is prepared as follows:

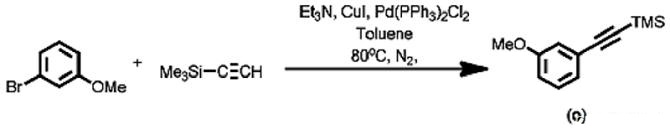

1) To 3-bromoanisole (5mL, 39.5mmol, 1 equivalent), triethylamine (22mL, 158mmol, 4 equivalents), CuI (0.75g, 4.0mmol, 10mol%) were added to toluene (50mL) Pd(PPh3)2Cl2 (1.4 g, 2.0 mmol, 5 mol%) in (trimethylsilyl)acetylene (6 mL, 43.5 mmol, 1.1 equiv). The reaction mixture was stirred at 80 °C for 5 h, then diluted with EA and washed with H2O (3 × 50 mL). The organic extracts were dried over MgSO4 and concentrated under reduced pressure. The crude product was purified by flash chromatography on silica gel using n-hexane/ethyl acetate (10:1) as eluent to give a colorless oil. Yield: 6.0g, 75%. 1HNMR (400MHz, CDCl3): δ7.20 (d, J=8.0Hz, 1H), 7.06 (d, J=8.0Hz, 1H), 6.99 (d, J=6.7Hz, 1H), 6.87 (d, J =8.0Hz, 1H), 3.75 (s, 3H), 0.19 (s, 9H).

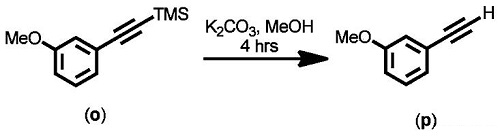

2) To a solution of the compound of step 1) (6g, 29.6mmol, 1eq) in MeOH (40mL) was added K2CO3 (2g, 14.8mmol, 0.5eq). After stirring at room temperature for 4 h, the mixture was diluted with Et2O and washed with H2O (3 × 50 mL). The organic extracts were dried over MgSO4 and concentrated under reduced pressure. The product 3-ethynyl anisole was obtained in a pale yellow oil. Yield: 3.5g, 90%. 1HNMR (400MHz, CDCl3): δ7.21 (t, J=8.0Hz, 1H), 7.08 (d, J=7.8Hz, 1H), 7.00 (d, J=7.8Hz, 1H), 6.79 (d, J =7.8Hz, 1H), 3.86 (s, 3H), 3.08 (s, 1H).

Apply[1]

3-Ethynyl anisole can be used as a pharmaceutical synthesis intermediate:

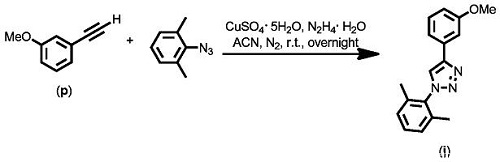

To a solution containing 3-ethynyl anisole (1.63g, 13.2mmol, 1.5eq), CuSO4·5H2O (0.22g, 0.88mmol, 0.1eq) and hydrazine hydrate (0.28mL, 8.8mmol, 1eq) 2-azido-1,3-dimethylbenzene (1.30 g, 8.8 mmol, 1 equivalent) was added to acetonitrile (50 mL). The mixture was stirred at room temperature under N2 atmosphere for 12 hours. The mixture was then diluted with dichloromethane and washed with H2O (3 × 50 mL). The organic extracts were dried over MgSO4 and concentrated under reduced pressure. The crude product was purified by flash chromatography on silica gel using n-hexane/ethyl acetate (10:1) as eluent to give a colorless oil. Yield: 1.7g, 71%. 1HNMR (400MHz, CDCl3): δ7.93 (s, 1H), 7.64 (s, 1H), 7.51 (d, J=6.6Hz, 1H), 7.43 (d, 8.0Hz, 1H), 7.38 (s, 1H ), 7.30–7.25 (m, 2H), 7.00–6.95 (m, 1H), 3.96 (s, 3H, -OMe), 2.12 (s, 6H).

Main reference materials

[1]WO2019144845

微信扫一扫打赏

微信扫一扫打赏