As a cost-effective coating technology, bottom surface integration is widely used in medium and light anti-corrosion fields such as auto parts, steel structures, mechanical equipment and engineering machinery. The development of water-based environmentally friendly coatings also poses challenges to the innovation of bottom-in-one water-based coatings: it must not only meet the complex and efficient construction baking and curing process, but also ensure competitive comprehensive application costs; in addition to providing beautiful features as a topcoat , gloss and scratch resistance requirements, but also need to solve many problems in the actual application process, such as the storage stability of the coating itself, the early water resistance, heat resistance and stacking resistance of the coating after construction, etc.

The most critical challenge in the development of water-based coatings for the bottom surface is: in addition to common cold-rolled steel plates, it is also necessary to achieve a coating similar to water-based epoxy on difficult substrates and complex workpieces such as galvanized plates and electrophoretic paints. Adhesion and anti-corrosion requirements, as well as UV aging resistance that far exceeds that of water-based epoxy coatings; when large-scale promotion and application, the constructability and stability of paint film performance in different application environments are also difficult, such as anti-sag, Drying performance, pot life, etc.

With the support of national environmental protection policies and after decades of development, domestic bottom-integrated water-based coating technologies have flourished, including water-based alkyd, water-based acrylic, water-based polyurethane, water-based epoxy and various modified hybrid resin technologies, etc. Almost all have achieved industrial application.

The two-component water-based epoxy-amine-cured all-in-one bottom coating stands out among many anti-corrosion coating technologies due to its excellent adhesion, anti-corrosion performance and chemical resistance. However, its biggest shortcoming is its insufficient anti-UV aging performance and easy yellowing. and powder. Most other bottom-surface integrated water-based resin technologies, including single-component epoxy and various epoxy-modified products, cannot be widely recognized for their substrate adhesion and 300-500 hours of salt spray anti-corrosion performance.

New water-based hybrid epoxy product EPIKOTE™ Resin 8310-WH-53A

Weisilei Epoxy Business Department has been developing water-based epoxy technology since the 1980s. The quality of the water-based epoxy product line has won a wide reputation in the fields of industrial anti-corrosion, civil construction and other fields. In 2023, based on the existing excellent anti-corrosion water-based epoxy technology, Weisilei developed a new water-based hybrid epoxy product EPIKOTE™

Resin

8310-WH-53A provides a wide range of possibilities to help customers develop integrated bottom products to meet different terminal needs, and the amount of amine curing agent required is reduced by two-thirds compared to the water-based epoxy formula, greatly reducing the cost of dual-group The cost of the base resin for a paint formulation.

Performance testing

EPIKOTE™ Resin

As a water-based hybrid epoxy product, 8310-WH-53A inherits the excellent storage stability of Weisilei’s water-based epoxy products and has a shelf life of at least 12 months under normal temperature packaging and airtight conditions. Even after 4 weeks of storage at 50°C, EPIKOTE™

Resin

The 8310-WH-53A product still appears normal, with no significant changes in viscosity and particle size. After formulating the coating according to the original proportions and dosage, it can still show good anti-corrosion and anti-UV aging performance within the 500-hour test period, with wet adhesion level 1 (figure 1.

); ΔE after 500 hours of aging in the UV resistance test is 0.6.

Secondly, EPIKOTE™ Resin

8310-WH-53A has its own viscosity less than 100mPa.s and has good operability. With appropriate rheology additives, a thick coating formula with a dry film thickness of about 150 microns can also be designed.

For example, in the two-coat and one-bake process, the dry film thickness of the first coat is 60-80 microns. Bake at 80°C for 30 minutes and then spray the second coat. The dry film thickness is 60-80 microns. The total film thickness is about 150 microns. Continue at room temperature. Cured for 7 days to test application performance. The sand-washed steel plate sample still performed well in the salt spray test for nearly 1,000 hours, with wet adhesion level 1 (Figure 2.

); This formula adds a small amount of water-based epoxy resin, and the ΔE after aging for 546 hours in the UV resistance test is 2.3.

In addition, EPIKOTE™ Resin

8310-WH-53A can be designed with a gloss (60°) value of 20GU or above through formula adjustment. Selecting the appropriate amine curing agent, auxiliary water-based resin, dispersant and co-solvent can result in a glossy paint formulation with balanced properties.

For example, adding one-component water-based epoxy can improve the gloss; adding EPIKOTE™ Resin 6520-WH-53A can not only improve salt spray resistance, but also improve the gloss.

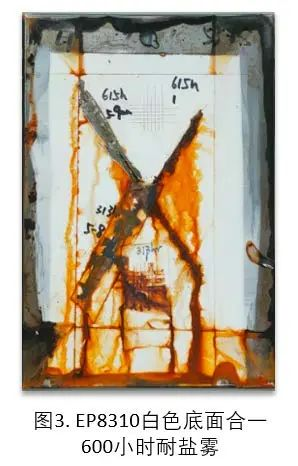

EPIKOTE™ Resin with around 20% PVC

8310-WH-53A is a reference formula with a white base and a gloss (60°) value of 20GU. After adding a small amount of other resins, the gloss (60°) value can reach more than 35GU. Without adding UV absorbers, the ΔE of this formula is 1.8 after a 300-hour UV resistance test, and the gloss retention rate is 79%; after a 600-hour UV resistance test, the ΔE is 2.2, and the gloss retention rate is about 54%. In good condition after 600 hours of salt spray testing, the wet adhesion is level 1.

In order to design a more stable gloss, the selection and addition process of co-solvent are also very important. Choosing the appropriate co-solvent matching and addition process can ensure that the paint film gloss, drying speed and paint film hardness reach an optimal balance.

Summary

EPIKOTE™ Resin

8310-WH-53A has good compatibility with a variety of different water-based epoxy resins, water-based amine curing agents, water-based acrylic resins, and one-component water-based epoxy design formulas. It can not only be used with other water-based epoxy resins and various water-based Amine curing agents are designed into two-component water-based hybrid epoxy systems with different designs. They can also be used to improve the adhesion, salt spray resistance or early water resistance of water-based systems such as acrylic resins and polyurethanes, broadening the diversity of anti-corrosion coating products developed for customers. Got the idea.

微信扫一扫打赏

微信扫一扫打赏