Overview[1]

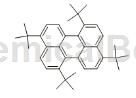

1,4,7,10-tetratert-butylperylene (TBPe) is a highly efficient fluorescent small molecule doped dye. Co-doping TBPe with MEH-PPV can improve the luminescence performance of the device and produce multi-layer structure devices, which can effectively reduce electrode quenching and improve the performance of electroluminescent devices.

Apply[1]

Jiang Lei rationally combined TBPe with other red and green light materials, designed experiments, and prepared white organic electroluminescent devices with a simplified structure. ITO/ PE DOT:PSS/MEH-PPV/TBPe/Al organic electroluminescent device, it was found that the optimal evaporation thickness of TBPe is 0.5nm, which increases the luminous intensity by 325% compared to the standard device without evaporation;

Prepared ITO/PEDOT:PSS/MEH-PPV:TBPe/TBPe/Liq/Al organic electroluminescent devices, studied the effect of different doping ratios on device performance, and found that the optimal doping ratio was 30%, compared with For devices without TBPe doping, the luminous brightness is increased by 44%, and the peaks of the luminescence spectrum are all located at 580nm. In addition, Alq3 is used to improve electron injection to produce Liq- and LiF-modified ITO/PEDOT:PSS/MEH-PPV:TBPe/TBPe/Alq3/Liq/Al, ITO/PEDOT:PSS/MEH-P PViTBPe/TBPe/Alqs/LiF /Al multi-layer device, the luminous brightness reaches 4162.2cd/m2 and 4701cd/m2.

Jiang Lei also produced two devices with different structures to realize OLED devices emitting white light. The first method uses TBPe and Rubrene blend evaporation to produce white-light OLED devices, achieving the purpose of OLED devices emitting white light. According to the energy level theory, the experimental device structure is designed as follows: ITO/NPB (50nm)/TBPe:Rubrene ( 40nm, Rwt=1%)/Alq3(40nm)/LiF(0.5nm)/Al(100nm). The device lights up at 4V, and reaches the maximum 2234cd/m2 at 9V. The color coordinate is at (0.3317, 0.3401). The luminescence spectrum is in three bands, and the color coordinate is in the center of the white area.

The second method uses TBPe spin coating method to make white light OLED devices, and also realizes white light OLED devices. The device structure is as follows: ITO/PVK:TBPe (wt%=95:5, 10mg/ml)/Alq3: Rubrene (40nm, Rwt%=1%)/LiF(0.5nm)/Al(100nm). The device made by this method lights up at 4V, and reaches the maximum 5185cd/m2 at 12.2V. The color coordinate is at (0.3411, 0.3874). The luminescence spectrum is dual-band. As the voltage increases, the brightness increases, and the luminescence reaches In the area above the white center, the device emits white light.

Main reference materials

[1] Jiang Lei. Research on organic electroluminescent devices based on TBPe materials[D]. Beijing Jiaotong University, 2015.

微信扫一扫打赏

微信扫一扫打赏