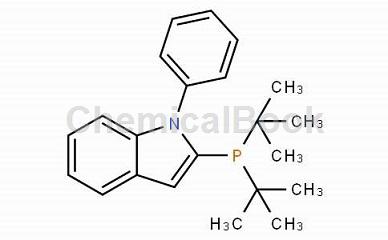

Background and overview[1]

2-Di-tert-butylphosphine-1-phenylindole can be used as a pharmaceutical synthesis intermediate and an organic intermediate. It is mainly used in laboratory research and development processes and chemical and pharmaceutical synthesis processes. If 2-di-tert-butylphosphine-1-phenylindole is inhaled, move the patient to fresh air; if skin contact occurs, remove contaminated clothing and rinse the skin thoroughly with soap and water. If discomfort occurs , seek medical attention; if eye contact occurs, separate eyelids, rinse with running water or saline, and seek medical attention immediately; if ingested, rinse mouth immediately, do not induce vomiting, and seek medical attention immediately.

Preparation[1]

2-Di-tert-butylphosphine-1-phenylindole is prepared as follows:

a) Synthesis of N-phenylindole

Place 0.19g (0.1mmol) of CuI, 2.34g (20mmol) of 1, 8.82g (42mmol) of K3PO4, 0.48ml (4mmol) of 1,2-diaminocyclohexane and 3.16ml (30mmol) 2 was stirred in 20 ml dry dioxane at 110 °C for 24 h. The mixture was then diluted with 50 ml of ethyl acetate. The purple precipitate was filtered through silica gel, resulting in a yellow solution, which was concentrated under vacuum (20 mbar, 50°C). The remaining orange oil was purified by column chromatography (silica gel, hexane/ethyl acetate 98/2). Yield: 3.0g (15.5mmol; 75%).

b) Synthesis of N-phenyl-2-(di-tert-butylphosphino)indole (2-di-tert-butylphosphine-1-phenylindole)

Add 1.6ml (15mmol) of TMEDA to 1.93g (10mmol) dissolved in 30ml of hexane. A solution of n-BuLi (6.25 ml, 10 mmol) (1.6 M in hexane) was added dropwise. After 3 hours of reflux (75°C), the color deepened from yellow to orange. Without cooling, a solution of 2.2 ml (10 mmol) chlorodi-tert-butylphosphine in 20 ml hexane was added dropwise. After refluxing for another hour, the color of the mixture became lighter again, and a white solid precipitated. After cooling, 30 ml of water was added to the mixture. The aqueous phase was extracted 3 times, using 20 ml of hexane each time. The combined organic phases were washed with 10 ml of water, dried over Na2SO4 and concentrated in vacuo (45°C). Boil the yellow residue in 30 ml MeOH for 30 minutes. After cooling to room temperature, the product obtained was filtered off (660 mg, 17%).

Main reference materials

[1] CN200480013398.7 Nitrogen-containing monodentate phosphine and its application in catalysis

微信扫一扫打赏

微信扫一扫打赏