Background and overview[1]

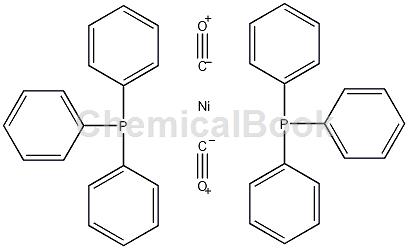

Bistriphenylphosphine nickel dicarbonyl can be used as pharmaceutical synthesis intermediates and organic intermediates, mainly used in laboratory research and development processes and chemical and pharmaceutical synthesis processes.

Preparation[1]

In a drying box, dissolve L-leucine NCA (9.2mg, 0.058mmol) in THF (0.5mL) and add evenly stirred PPh3 (31mg, 0.12mmol) and (COD)2Ni (16mg, 0.058) in the mixture. mmol) in THF (1.5 mL). The red/brown solution was stirred for 24 hours, then the solvent was removed in vacuo to give a dark red oily solid. The product was extracted with cold hexane (0°C, 3×2). A red/brown hexane solution and a light orange solid were obtained. Evaporation of the hexane solution gave a red oil containing (PPh3)2Ni(CO)2[IR(THF): 2000, 1939cm-1(nCO).

The solid was then dried to give an orange powder, which could be purified by precipitation from THF/hexane to give bistriphenylphosphine nickel dicarbonyl (5 mg, 66% yield). The product was dissolved in THF (5 mL) in a round bottom Schlenk flask in a dry oven. Place the flask under a N2 atmosphere on the Schlenk line and add HCl (90 mL of a 1.0 MEt2O solution). The yellow solution turns orange and then becomes hazy as it slowly turns green. After 2 hours, the solvent was removed in vacuo to obtain bistriphenylphosphine nickel dicarbonyl.

Apply[2]

Bistriphenylphosphine nickel dicarbonyl can be used as pharmaceutical synthesis intermediate: 3, 3, 4, 4, 5, 5, 6, 6, 6-nonafluorohex-1-ene (20.5 g, 0.0833 mol) , bistriphenylphosphine nickel dicarbonyl (0.53 g, 0.0008 mol), and perfluoroethyl iodide (153.6 g, 0.625 mol) were added to a 210 ml HastelloyTM shaking tube and heated at 100°C for 8 hours under autogenous pressure. . Analysis of the product by GC-MS showed the presence of C4F9CHICH2C2F5 (64.3 GC area %) and the diadduct (3.3 GC area %); 3,3,4,4,5,5,6,6,6-nonafluorohexane-1 The conversion rate of -ene is 80.1%.

Main reference materials

[1]US6632922Methods and compositions for controlled polypeptide synthesis

[2]WO2008097638LASER-ASSISTEDETCHINGUSINGGASCOMPOSITIONSCOMPRISINGUNSATURATEDFLUOROCARBONS

微信扫一扫打赏

微信扫一扫打赏