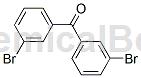

Overview[1][2]

Bis(3-bromophenyl)methanone is a ketone organic compound and an important type of organic synthesis intermediate. It is widely used in the fields of medicine, pesticides, polymer materials and other fields. Many natural products and pharmaceutically active molecules contain symmetrical diaryl ketone backbone structures. Friedel-Crafts acylation is the most traditional method for preparing symmetric diaryl ketones. This method usually requires the addition of excess Lewis acid and produces a large amount of three wastes. In addition, this method has poor substrate applicability and is only suitable for electron-rich substrates.

To overcome this limitation, many transition metal-catalyzed coupling methods have been developed for the preparation of symmetric diaryl ketones in the past two decades. Among these methods, the most direct and simple method is the catalytic oxidative carbonylation method of 2 molecules of arylboronic acid and 1 molecule of carbon monoxide (CO). Compared with other methods, this route has the advantages of simple and easily available raw materials, short reaction steps, and high atom economy. Palladium is an effective catalyst for this oxidative carbonylation reaction. In addition, since this method involves the coupling of two carbon nucleophiles, it usually also requires the consumption of equivalent oxidants. The reported oxidants include AgNO3, I2 and O2. Among these oxidants, O2 is undoubtedly the best oxidant, with high atom economy, low price, environmental friendliness, and the most promising industrial application prospects.

Structure

Preparation method[1]

Add 3-bromophenylboronic acid (0.249g, 2mmol), 5wt% Pd/CaCO3 (0.0456g, Pd0.01mmol) and CuI (0.0114g, 0.03mmol) into a 250mL polytetrafluoro-lined pressure reactor , then add DMSO (10mL), install the reaction kettle, slowly introduce 1.85atm of air in the fume hood, and then introduce 0.15atm of CO, and then place the reaction kettle in a 50°C oil bath for 12 hours. . After the reaction has stopped, cool the reaction kettle to room temperature and slowly release the remaining gas in the kettle in a fume hood. Open the reaction kettle, add 40 mL of ammonia water with a mass concentration of 5%, filter and separate the palladium catalyst, which can be reused after washing and drying. The mother liquor was extracted three times with dichloromethane (30 mL), and the organic phases were combined. The organic phase was dried over anhydrous sodium sulfate, concentrated in vacuo to remove the solvent, and the crude product was purified by column chromatography (volume ratio 20:1 petroleum ether/ethyl acetate). eluent) to obtain bis(3-bromophenyl)methanone as a white solid, melting point: 47~49°C.

Main reference materials

[1]CN201811541806.6 A method for preparing symmetric diaryl ketones by catalytic oxidative carbonylation

微信扫一扫打赏

微信扫一扫打赏