Background and overview[1]

2,5-Dimethyl-4-hydroxybenzonitrile can be used as a pharmaceutical synthesis intermediate.

Preparation[1]

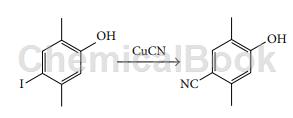

The preparation of 2,5-dimethyl-4-hydroxybenzonitrile is as follows:

The specific steps are:

1) Dissolve 0.02 mol of 2,5-dimethylphenol and equal amounts of sodium iodide and sodium hydroxide in 50 mL of methanol. Cool the solution in an ice bath until the temperature reaches 0 °C. In another suitable neck flask add a funnel solution containing 37.5 ml of sodium hypochlorite 4% w/w. Slowly drop this solution into the flask without exceeding 4∘C. Stir the mixture with the help of magnetic stirring and after adding all the solution from the funnel, stir the mixture for another 2 hours with stirring at a temperature of 0 to 2°C. The resulting solution is treated with 40 mL of aqueous sodium thiosulfate (Na2S2O3) solution 1, then the pH is adjusted to 7.0 with 10% hydrochloric acid. In some cases, the product crystallizes at this point and can therefore be filtered. When no crystallization occurs, add 50 mL of chloroform, dry with anhydrous calcium carbonate and then filter the solution. Filter the solution and fractionate the solvent under reduced pressure to obtain 4-iodo-2,5-dimethylphenol with a yield of 75% and a melting point of 50 %.

2) Dissolve 4-iodo-2,5-dimethylphenol in 20mL N,N-dimethylformamide (DMF) and add the mixture to the addition funnel. An equal amount of molar 10% copper cyanide was dissolved in 20 mL DMF and added to the three-way flask. Start heating with the help of a magnetic stirrer and a heater. When reflux begins, the entire solution is slowly added dropwise in the dropping funnel. After the addition is completed, the solution was continuously refluxed for 6 hours to allow the solution to reach room temperature, and then added to 40 mL of saturated ethylene glycol solution of ethylenediaminetetraacetic acid and stirred for 24 hours. After this stage, the solution is cooled to obtain better crystals and then filtered. Chemical activation of the extraction solvent is used to purify the product. The product is first dissolved in chloroform and then the entire mixture is transferred to a separation funnel and washed 5 times with 5% sodium hydroxide. The aqueous extract was adjusted to pH 7.0 with concentrated hydrochloric acid drops, and a precipitate was obtained, filtered and dried in a vacuum desiccator. The product 2,5-dimethyl-4-hydroxybenzonitrile was obtained with a yield of 35% and a melting point of 121∘C.

Main reference materials

[1] Synthesis and Characterization of PPV Monomer for Subsequent Electropolymerization

微信扫一扫打赏

微信扫一扫打赏