Overview[1][2]

Aciodobenzoic acid is an acid derivative that can be used as a pharmaceutical synthesis intermediate.

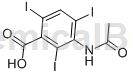

Structure

Preparation method[1]

The specific steps for preparing 3-acetamido-2,4,6-triiodo-benzoic acid (acetoiodobenzoic acid) are as follows:

Add 2.60 g (0.005 mol) 3-amino-2,4,6-triiodo-benzoic acid, 100 ml anhydrous chloroform and 6 to 8 drops of concentrated sulfuric acid into the reaction vessel. The mixture was heated to reflux and then 0.2 g (0.005 mol) of ketone (at a rate of 0.2 ml/sec) was added over 2 h followed by an excess of 0.1 g. After the reaction is completed, 1g of activated carbon is added and heated under reflux for 20 minutes, the carbon is filtered off, and the chloroform is evaporated in vacuum. Add 40-50 ml of distilled water to the residue, basify it to pH 8 with 30% NaOH, and then add 1 g of activated carbon. The mixture was boiled for 20 minutes, the carbon was filtered off, and the filtrate was acidified to pH 1 with concentrated hydrochloric acid. After cooling, the precipitate is separated, filtered off and washed with distilled water until the wash reaches pH 7. The purification process was repeated and the product thus obtained was dried under vacuum at 60°C. Obtained 1.4 g (50%) of pure acetamido-2,4,6-triiodo-benzoic acid (acetoiodobenzoic acid), m.p. 281-2820C.

Apply[1]

Preparation of 3,5-diacetamido-2,4,6-triiodo-benzoic acid: Add 0.005 mol of acetoiodobenzoic acid, 100 ml of benzene and 6 to 8 drops of concentrated sulfuric acid in the reaction vessel. Heat the mixture to 70-80°C, then add 0.4g (0.01 mol) of ketene over 2 hours (at a rate of 0.4ml/second), followed by an excess of 0.2g of ketene. When the reaction is complete, add 1 g of activated carbon and continue stirring for 20 minutes. The carbon is filtered off and the benzene is evaporated in vacuum. Add 40 ml of distilled water to the residue to make it alkaline. Add 30% NaOH to pH 8 and 1g activated carbon, boil the mixture for 10 minutes, filter out the activated carbon, and acidify the filtrate to pII1 with concentrated hydrochloric acid. After cooling, the precipitate was separated, filtered out and washed with distilled water until the pH was 7. The purification was repeated and the resulting product was dried under vacuum at 60 °C to obtain 1.61 g (52%) of pure precipitate 3,5-bis. Acetamido 2,4,6-triiodo-benzoic acid, mp 300-3030C.

Main reference materials

[1] (GB1407138) PROCESS FOR PREPARING ACETYLAMINO DERIVATIVES OF 2,4,6- TRIIDOBENZOIC ACID

微信扫一扫打赏

微信扫一扫打赏