Background and overview[1]

2-Nitroaniline-4-sulfonic acid is an important intermediate in the synthesis of organic pigments. Using it as a diazo component, a series of pigment varieties with excellent performance can be produced, such as C.1. Pigment Yellow 61, 62, 165, 169, etc. According to literature reports, the synthesis methods of this intermediate include the ammonolysis method of 4-chloro-3-nitrobenzene sulfonic acid; the sulfonation method of o-nitroaniline using sulfuric acid or chlorosulfonic acid as the sulfonating agent respectively; the first method , the reaction needs to be carried out under a certain pressure, and the synthesis process is also more complicated; the solvent used in the second method is a mixture of monochlorobenzene and dichlorobenzene, and the product yield using sulfuric acid as the sulfonating agent is 89.3%, and using chlorosulfonate as the sulfonating agent The product yield when acid is the sulfonating agent is 90%. Both solvents and chlorosulfonic acid are more expensive. The choice of solvent is not only directly related to the temperature and time of the sulfonation reaction, but also directly affects the composition of the product cost, which in a sense plays a decisive role.

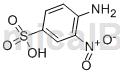

Structure

Preparation[1]

Add 60ml mixed solvent and 0.1mol o-nitroaniline into a four-necked bottle equipped with a stirrer, dropping funnel, condenser and thermometer. While stirring, use an oil bath to gradually heat up to melt, and then slowly Drop in concentrated sulfuric acid to form a salt. After the dripping is completed, after the salt is completely formed, the temperature is slowly raised to 160°C and maintained for 5 hours to carry out dehydration transposition reaction. During the reaction, the solvent is continuously dripped and the solvent is continuously evaporated, keeping the total solvent amount in the reactor basically unchanged. After the reaction, cool down, pour out the solvent, add water, and add a small amount of anhydrous sodium sulfite, and wait until it dissolves. Then use Na2CO3 solution to adjust pH=8-9, filter, discard the filter residue, put the filtrate into saturated salt water, add a small amount of anhydrous sodium sulfite, acidify with hydrochloric acid to pH 22, let it stand to fully crystallize, filter, and wash. , dried to obtain 2-nitroaniline-4-sulfonic acid product.

Main reference materials

[1] Research on the synthesis of 2-nitroaniline-4-sulfonic acid

微信扫一扫打赏

微信扫一扫打赏