Background and overview[1][2]

2-Methyl-3-aminophenol can be used as an intermediate for pharmaceutical and chemical synthesis. If 2-methyl-3-aminophenol is inhaled, move the patient to fresh air; if there is skin contact, take off contaminated clothing, rinse the skin thoroughly with soap and water, and seek medical attention if you feel uncomfortable; if the eyes If exposed to sunlight, separate eyelids, rinse with running water or saline, and seek medical attention immediately; if ingested, rinse mouth immediately, do not induce vomiting, and seek medical attention immediately.

Preparation [2, 4-5]

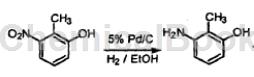

Dissolve 2-methyl-3-nitrophenol (25g, 0.163mol) in 170ml of absolute ethanol in a hydrogenation flask. Purge the flask with nitrogen. 10% palladium on carbon (1.73g, 1.6mmol) was added and the mixture was hydrogenated (40psi (2758hPa) H2) in the apparatus for 1.5 hours. The flask was evacuated and purged with nitrogen. Whatman GF/F filters remove catalyst by filtration. After removal of ethanol under reduced pressure, 20.1 g (100% yield) of 2-methyl-3-aminophenol were obtained as a light brown solid.

Application

2-Methyl-3-aminophenol can be used as a pharmaceutical intermediate, such as synthesis:

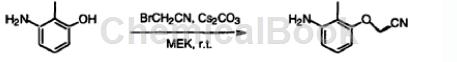

Step 1: Dissolve 2-methyl-3-aminophenol (20.1g, 0.163mol) in methyl ethyl ketone (MEK) (150ml). Cesium carbonate (106g, 0.326mmol) was added in portions, followed by bromoacetonitrile (29.3g, 0.245mol) dropwise over 30 minutes. The mixture was stirred at room temperature for 14 hours and then filtered through a coarse fritted funnel. The solid was washed with ethyl acetate (2 × 100 ml), and the combined washings and filtrate were concentrated under reduced pressure to obtain 20.8 g (79% yield) (2-methyl-3-aminophenoxy)acetonitrile without further purification. .

Step 2: Add pyridine (6.6 mL) and methanesulfonyl chloride (6.3 mL) and the resulting mixture was warmed to ambient temperature. After 2 hours, the crude product mixture was partitioned between 1N hydrochloric acid (100 mL) and ethyl acetate (100 mL). The phases were separated and the aqueous phase was extracted with ethyl acetate (50 mL). The combined organic solutions were washed with water and concentrated while replacing the solvent with isopropanol. After the resulting mixture was cooled to 5℃, the white crystalline product was collected, rinsed with cold isopropyl alcohol, and dried to obtain 12.14g (yield based on cyanomethyltosylate 65.1%) N -(3-Cyanomethoxyphenyl)methanesulfonamide (99.8% purity).

Main reference materials

[1] EP0887346. Phenyl-and aminophenyl-alkylsulfonamide and urea derivatives, their preparation and their use as alpha1A/1L adrenoceptor agonists

微信扫一扫打赏

微信扫一扫打赏