Background and overview[1]

Methylaniline is o-methylaniline (2-Methylaniline), 3-methylaniline (3-Methylaniline) ), the collective name of p-methylaniline (4-Methylaniline). O-methylaniline and 3-methylaniline are colorless oily liquids, and p-methylaniline is white crystal. Methylaniline is one of the simplest aromatic amines and a widely used organic synthesis intermediate. It is widely used as an organic synthesis intermediate for dyes, pesticides, medicines, etc. At present, domestic production mainly uses nitrotoluene as raw material, ethanol or methanol as solvent, and skeleton Ni as catalyst to perform hydrogenation reaction to prepare methylaniline. The disadvantage of this process is that an external solvent methanol or ethanol is introduced during the reaction. The solvent methanol or ethanol consumes a lot of energy, is flammable and explosive, and methanol is toxic. Therefore, the production cost of the entire process is high and the safety factor is low. Not environmentally friendly.

Apply[2-6]

3-methylaniline is mainly used as an intermediate in organic and chemical synthesis. Examples of its applications are as follows:

1. Preparing a conductive polymer-based electrochromic film, which belongs to the technical field of polymer electrochromic materials. This method involves copolymerizing three monomers: aniline, 3-methylaniline and 3,4-isopropyldioxythiophene through chemical oxidation to prepare a ternary conductive copolymer, which is separated and combined with polyamide polymers. A blended solution is formed, and the blended solution is sprayed, brushed, or immersed on the surface of the conductive glass or conductive film. After the solvent evaporates, a conductive polymer-based electrochromic film is obtained. The method of the invention has simple preparation process, strong processability and low cost, and the prepared electrochromic film has good characteristics, high adhesion force and wide applicability. After the above products are combined with the ion conductive layer and the ion absorption layer, various forms of electrochromic glass, thin films and other devices can be easily prepared.

2. Prepare a hydrolysis-resistant polycarbonate composite material, which contains 3-methylaniline and During the preparation of components such as fluorine compounds, each component is first reacted with polycarbonate and silicone-polycarbonate copolymers with different molecular weights to form the No. 1 base material and the No. 2 base material to ensure that the separation between each component is It can fully react and improve the mixing effect. At the same time, the reaction temperature, extrusion temperature and other process parameters are strictly controlled to improve the reaction effect of the components, achieve the “synergistic” effect, and greatly improve the performance of the product. It has been proven by experiments , the hydrolysis-resistant polycarbonate composite material prepared by the above method has excellent thermal deformation resistance and high temperature resistance and hydrolysis resistance. It can be widely used in housings in various fields and can still have excellent use in harsh environments. life.

3. Preparing a clutch pump piston material, the preparation method includes:

1) Crush sweet potatoes, then place them in yeast solution for fermentation, and then filter the filter cake to prepare the modifier ;

2) Calcining bentonite and iron slag, and then activating it in the presence of X-rays to produce Activator;

3) Combine polycarbonate, ethylene-vinyl acetate copolymer, cellulose propionate, vinyl propionate, n-butyl Alcohol, nano magnesium oxide, rare earth oxide, potassium titanate whisker, 3-methylaniline, anilinomethyltriethoxysilane, pyrimidine, p-benzoquinone, dimethyl silicone oil, modifier and activator are mixed , cooling molding, and granulation to prepare clutch pump piston materials. The clutch pump piston material prepared by this method has excellent mechanical properties.

4. Prepare a high-strength clutch fork material. The preparation method includes:

1) Soak sawdust and plant ash in hydrochloric acid solution, then filter the filter cake, and then steam the filter cake to Prepare modifier;

2) Calcining bentonite and iron slag, and then activating it in the presence of X-rays to produce Activator;

3) Combine polycarbonate, ethylene-vinyl acetate copolymer, cellulose propionate, vinyl propionate, n-butyl Alcohol, nano magnesium oxide, rare earth oxide, potassium titanate whisker, 3-methylaniline, anilinomethyltriethoxysilane, pyrimidine, p-benzoquinone, dimethyl silicone oil, modifier and activator are mixed , cooling molding, and granulation to produce high-strength clutch fork materials. The clutch fork material prepared by this method has excellent mechanical properties.

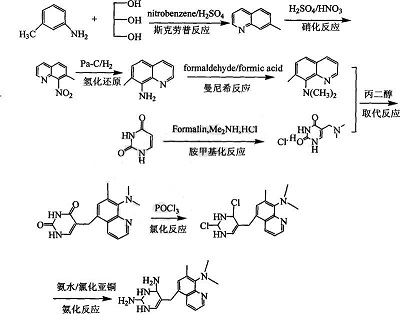

5. Preparation of a new sulfonamide synergist 2,4-diamino-5-(8-dimethylamino- 7-Methyl-5-quinolylmethyl)-2,4-(1H,3H)pyrimidine. With uracil, 3-methylbenzeneAmine, glycerol and m-nitrotoluene are used as raw materials, and they undergo amine methylation reaction, Scrop reaction, nitration reaction, hydrogenation reduction reaction, amine methylation reaction, substitution reaction, chlorination reaction and ammoniation reaction in sequence, and finally Synthesis of 2,4-diamino-5-(8-dimethylamino-7-methyl-5-quinolylmethyl)-2,4-(1H,3H)pyrimidine. Advantages of this method: the raw materials used are easily available and cheap, the reaction conditions are relatively mild and the process is simple, easy to control, the required equipment is simple, the total reaction yield is high, 20.3%, and it is easy to industrialize production.

Preparation [1]

Put the weighed m-nitrotoluene and nanocatalyst into the high-pressure reaction kettle, and replace the reaction kettle with nitrogen three times ( Substitution pressure 0.3MPa), start stirring; open the hydrogen cylinder pressure reducing valve and pressure regulating valve, control the hydrogen pressure, fill an appropriate amount of hydrogen into the high-pressure reaction kettle, and heat it to the temperature in the kettle to the set temperature; continue stirring and pouring Pour hydrogen into the kettle, and at the same time flow cooling water into the reactor to remove the heat of reaction and keep the reaction temperature stable; when the pressure of the reactor begins to rise, stop flowing hydrogen and cooling water, continue stirring and heating to maintain the reaction temperature for 0.5h; stop stirring, Separate the catalyst and reaction liquid, take out 30% (mass) of the reaction liquid under appropriate conditions, weigh it, obtain 3-methylaniline and analyze the main content. It is feasible to use methylaniline as a solvent and use nanocatalysts to catalytically hydrogenate nitrotoluene to prepare 3-methylaniline. The catalyst and solvent can be recycled. The process is safe and environmentally friendly, with low cost and low energy consumption. The optimal process indicators are: the ratio of the addition amount of nitrotoluene to methylaniline is 4:10 (mass ratio), the addition amount of nanocatalyst is 10% of the addition amount of nitrotoluene, and the reaction temperature is 100~ 120℃, H2 pressure 1.20~1.40 MPa, stirring rate 1500r/min. Under these reaction conditions, the conversion rate of nitrotoluene reaches more than 88.5%, and the selectivity of methylaniline reaches 100%.

Main reference materials

[1] Wu Hongbin. New process for preparing methylaniline by catalytic hydrogenation of nitrotoluene[J]. Anhui Chemical Industry, 2014, 40(4): 23-27.

[2] CN201210087452.9 A conductive polymer-based electrochromic film and its preparation method

[3] CN201711413379.9 Hydrolysis-resistant polycarbonate composite material and preparation method thereof

[4] CN201510976580.2 Clutch pump piston material and preparation method thereof

[5] CN201510976276.8 High-strength clutch fork material and preparation method thereof

[6] CN201110047437.7 A kind of 2,4-diamino-5-(8-dimethylamino-7- Preparation method of methyl-5-quinolylmethyl)-2,4-(1H,3H)pyrimidine

微信扫一扫打赏

微信扫一扫打赏