Background and overview[1][2]

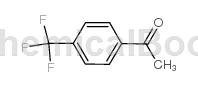

The Chinese alias of 4′-trifluoromethylacetophenone is p-trichloromethylacetophenone, chemical formula C9H7F3O. Molecular weight 188.14600. White solid, density 0.92, melting point 30-33 °C (lit.), boiling point 79-80 °C 8 mm Hg (lit.), flash point 184 °F. 4′-Trifluoromethylacetophenone can be used as an intermediate for pharmaceutical and chemical synthesis. If 4′-trifluoromethylacetophenone is inhaled, move the patient to fresh air; if there is skin contact, take off contaminated clothing, rinse the skin thoroughly with soap and water, and seek medical attention if you feel unwell; if In case of eye contact, separate eyelids, rinse with running water or saline, and seek medical attention immediately; if ingested, rinse mouth immediately, do not induce vomiting, and seek medical attention immediately.

Structure

Preparation [2, 4-5]

Method 1: Add 41.6g chlorocyclohexane (0.35mol) dropwise to a suspension of 4.65g lithium particles (0.68mol) in 350g THF at -55°C and select 2 hours of addition time. After >97% conversion of chlorocyclohexane as determined by GC (10 hours in total), 38.3 g of 4-bromotrifluorotoluene (0.170 mol) was added dropwise over 15 minutes at the same temperature. After stirring for a further 30 min at -50°C, the reaction mixture was added to 25.5 g of acetic anhydride (0.25 mol) in 50 g of THF at -30°C (30 min). After stirring for a further 30 minutes, the reaction mixture was poured into 120 g of water, the pH was adjusted to 6.3 with 37% HCl and the low boilers were distilled off under slight vacuum at 45°C. The organic phase was separated and the aqueous phase was extracted twice with 70 ml of toluene each time. The combined organic phases were fractionated under vacuum to obtain 29.5 g of 4-trifluoromethylacetophenone as a colorless liquid (0.157 mol, 92.2%), GC purity >98% a/a.

Method 2: Add 41.6g chlorocyclohexane (0.35mol) dropwise to a suspension of 4.65g lithium particles (0.68mol) in 350g THF at -55°C and select 2 hours of addition time. After the conversion of chlorocyclohexane was >97% as determined by GC (10 hours in total), a mixture of 38.3 g of 4-bromotrifluorotoluene (0.170 mol) and 7.0 g of acetonitrile (0.170 mol) was added dropwise at the same temperature. Lasts 15 minutes. After stirring for a further 30 minutes at -50°C, the reaction mixture was slowly thawed to room temperature and subjected to aqueous work-up in the usual manner. :The yield of 4-trifluoromethylacetophenone after distillation is 81%.

Main reference materials

[1]Wehle, Detlef; Forstinger, Klaus; Meudt, Andreas Patent .US20050001333.Method for producing, via organometallic compounds, organic intermediate products

微信扫一扫打赏

微信扫一扫打赏