Background and overview[1][2]

The Chinese alias of 2-methyl-1,4-phthalic acid is 2-methylterephthalic acid, CAS number 5156-01-4, chemical formula C9H8O4. Molecular weight 180.15700. Density 1.377g/cm3 3, boiling point 388.2ºC at 760mmHg, flash point 202.8ºC, refractive index 1.611. 2-Methyl-1,4-phthalic acid can be used as a pharmaceutical and chemical synthesis intermediate. If 2-methyl-1,4-phthalic acid is inhaled, move the patient to fresh air; if there is skin contact, take off contaminated clothing, rinse the skin thoroughly with soap and water, and seek medical attention if you feel unwell. ; If eye contact occurs, separate eyelids, rinse with running water or saline, and seek medical attention immediately; if ingested, rinse mouth immediately, do not induce vomiting, and seek medical attention immediately.

Apply[1]

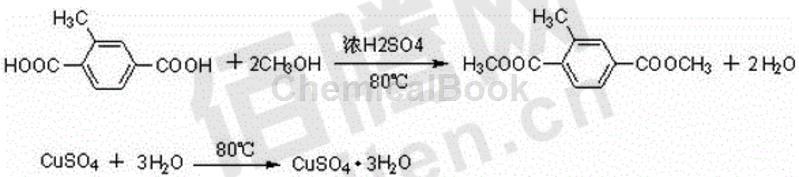

2-Methyl-1,4-phthalic acid can be used as an intermediate for pharmaceutical and chemical synthesis. Such as the synthesis of 2-methylterephthalate dimethyl ester. Dimethyl 2-methylterephthalate is an important compound in the process of synthesizing vinyl terephthalic acid-based chitosan liquid crystal polymers. At present, most of them are synthesized using acid catalysis, and the yield is relatively low, only about 33%. , the loss of raw materials is relatively large. Since 2-methylterephthalate dimethyl ester is a necessary intermediate for the synthesis of vinyl terephthalic acid-based chitosan liquid crystal polymers, it is of great significance to improve its yield. However, most acid-catalyzed esterification The reaction has the problem of low conversion rate. In this reaction, methanol serves as both a reaction reagent and a solvent. Methanol has a low boiling point, and no suitable water-carrying agent can be found to use an oil-water separator to remove water. Therefore, on the basis of existing research, anhydrous copper sulfate powder with strong water absorption is added. In an 80°C environment, anhydrous copper sulfate can combine with 3 water molecules, thereby increasing the esterification conversion rate. The results of infrared IR and nuclear magnetic NMR analysis of the obtained product showed that the synthesized compound was correct, which laid the foundation for the next step of large-scale synthesis of vinyl terephthalic acid-based chitosan liquid crystal polymers. The specific preparation method is as follows: 2-methylterephthalic acid is used as raw material, and the following steps are included in sequence: 1) Esterification: 2-methylterephthalic acid and methanol are catalyzed by concentrated sulfuric acid at 80°C. Esterification reaction, the reaction time is 8h~12h, the material ratio of 2-methylterephthalic acid and methanol is 1:10; 2) Water absorption: use anhydrous copper sulfate as the water absorbing agent, add anhydrous sulfuric acid to the above mixed solution The weight ratio of copper, 2-methylterephthalic acid and anhydrous copper sulfate is 20:17~1:1; 3) Extraction: Use methylene chloride as the extractant to separate the lower organic phase; 4) Recrystallization: The obtained crude 2-methylterephthalate dimethyl ester is recrystallized in petroleum ether to obtain 2-methylterephthalate dimethyl ester.

Preparation [2]

2-Methylterephthalic acid is synthesized by oxidizing 2,4-dimethylbenzoic acid with potassium permanganate under alkaline conditions. Add a certain mass of 2,4-dimethylbenzoic acid and sodium hydroxide to the flask, add water and stir to dissolve, then add potassium permanganate into the solution in batches, and continue the reaction at a certain temperature after the addition. 5 hours, after the reaction is completed, filter to remove the manganese dioxide solid, retain the filtrate, add concentrated hydrochloric acid to the filtrate to pH=2, a large amount of white precipitate will be generated, filter and dry to obtain a white powdery solid, which is 2-methylp-benzene. Dicarboxylic acid.

Main reference materials

[1] CN201510602110.X A kind of synthesis method of 2-methyl terephthalate dimethyl ester

[2] Zhang Ji. Synthesis and basic properties of new shell-type liquid crystal polymers containing aramid bonds [D]. Donghua University, 2012.

微信扫一扫打赏

微信扫一扫打赏