[Overview][1]

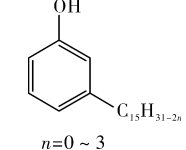

Cardanol is made from natural cashew nut shell liquid and refined through advanced technology. It is a green and environmentally friendly industrial raw material. Because of its low price, abundant sources, excellent performance, and reproducibility, it has become a research hotspot in recent years and has been widely used in the fields of coatings, adhesives, laminated resins, and anti-friction materials. The structural formula of cardanol is as follows. It has the characteristics of both aromatic compounds and aliphatic compounds. At the same time, the phenolic hydroxyl group on the benzene ring gives it the properties of phenolic compounds.

Cardanol surfactant has excellent biodegradability and is called a green surfactant or biomass surfactant. It is expected to replace petroleum phenolic surfactants. In recent years, cardanol has been intensively studied by domestic and foreign scholars, and good results have been obtained by using it as a lipophilic base to prepare surfactants.

1 Anionic surfactant

1. 1 Cardanol sulfonate

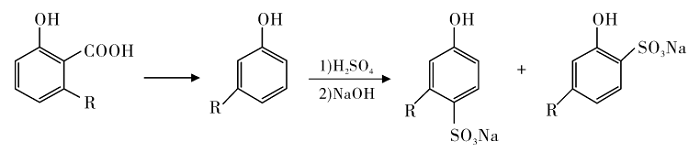

Peungjitton et al. used cashew nut shell liquid as raw material to prepare cardanol sulfonate surfactant. The synthesis route is as follows. Its surface activity was measured and compared with LAS. The results show that when the mass fractions of cardanol sulfonate and LAS are both 20%, the surface tensions of the solutions are 32. 25 and 28.00 mN/m respectively; cmc are 0. 372 and 0.435mmol/L respectively. Through comparison, it can be found that cardanol sulfonate has good surface activity, which provides a basis for its replacement of traditional petroleum-based surfactants.

1. 2 Cardanol sulfate

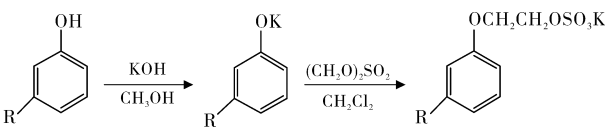

Bruce et al. used cardanol as raw material, methanol as solvent, and reacted with vinyl sulfate to synthesize cardanol polyoxyethylene ether sulfate salt. The yield reached 78%. The synthesis route is as follows.

Quan Chunsheng et al. prepared cashew nuts using cardanol polyoxyethylene ether as raw material.Phenol polyoxyethylene ether sulfate ammonium salt. This method has the advantages of simple equipment, excellent product quality, and no waste pollution. Zhou Yawen et al. studied the emulsifying properties and foam properties of cardanol polyoxyethylene ether ammonium sulfate. Through experiments, it was found that the pseudo-ternary phase diagram of cardanol polyoxyethylene ether ammonium sulfate/n-butanol/alkane/water can form a liquid crystal region and a large-scale O/W microemulsion region, and the emulsifying performance is at a mass fraction of 0.025%. Stronger in hard water; cardanol polyoxyethylene ether ammonium sulfate has low foaming properties.

1. 3 Cardanol carboxylate

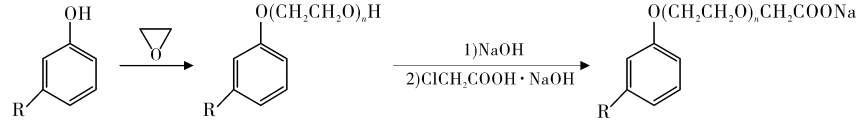

Scorzza et al. used cardanol as raw material to prepare cardanol carboxylate surfactant. The specific synthesis route is as follows. The yield of the product sodium cardanol carboxylate is 41.5%. The carboxylate surfactant has strong hydrophilicity, good surface activity and low critical micelle concentration.

The structural diversity of cardanol carboxylate makes its performance adjustable, and different structures can be designed according to different application characteristics.

2 cationic surfactant

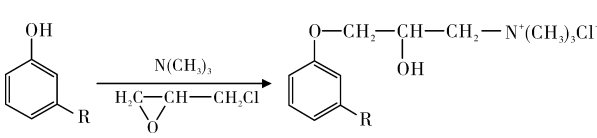

Wang Jun et al. used cardanol, epichlorohydrin and trimethylamine as raw materials to prepare a new cardanol cationic surfactant with a yield of 56%, of which The quaternary ammonium salt content is 80%, and the synthesis route is as follows. The cmc and γcmc of this cationic surfactant are 4. 83 mmol /L and 28. 62 mN /m respectively, showing good surface activity.

3 nonionic surfactant

Cardanol polyoxyethylene ether is a new generation of mild, safe, green, natural and environmentally friendly nonionic surfactants. It has a good synergistic effect with anionic surfactants and has excellent wetting, It has the properties of penetration, emulsification, dispersion and decontamination, and biodegrades rapidly and completely. It can be widely used in various detergents and personal care products. Xu Xiaomin studied the application performance of cardanol polyoxyethylene ether and fatty alcohol polyoxyethylene ether (JFC). When cardanol polyoxyethylene ether and JFC are compounded at a mass ratio of 2:3, it can achieve Better metal cleaning effect.

4 amphoteric surfactants

Wu Meiyun et al. used cardanol and epichlorohydrin as raw materials and tetrabutylammonium bromide as the catalyst to synthesize the intermediate cardanol chlorohydrin ether, and then synthesized cardanol tertiary amine through amination with dimethylamine. The product was then mixed with Sodium 3-chloro-2-hydroxypropanesulfonate undergoes the final reaction to prepare cardanol betaine type amphoteric surfactant. It was measured through experiments that the cmc of cardanol betaine is 3. 17×10-4 mol /L, and the γcmc is 32. 86 mN /m. This surfactant can effectively reduce the oil/water interfacial tension in the range of 0.5~3.0 g/L (to 10-4~10-3 mN /m); can produce a synergistic effect with polyacrylamide, reducing the oil/water interfacial tension to 10-6~10-4 mN /m; in surfactants When the mass concentration is 0.5~2.5g/L, the water separation time of the polymer/surfactant binary system is 200~1200 s, which is much higher than the 36 s of a single surfactant. The binary system has excellent emulsification performance. It is of great significance to reduce oil displacement costs and recover trapped crude oil. Xing Xinxin studied the interfacial properties of the synthesized cardanol betaine surfactants (C15SB-Ⅰ and C15SB-Ⅱ). The results showed that: C15SB-Ⅰ and C15SB-Ⅱ were at 0. 3 ~ 0. 5 g / L When , it can reduce the interfacial tension of Tuha and Saudi oil-water systems to ultra-low values (less than 10-3 mN/m); C15SB-Ⅰ has excellent temperature resistance and can The dynamic interfacial tension equilibrium values of Tuha and Saudi oil-water systems reach 4. 67×10-3 and 1. 23×10– 3 mN/m respectively; C15SB- Solution I can reduce the interfacial tension of the Tuha oil and water system and maintain an ultra-low value within the range of a salinity of 80 to 270 g/L and a total calcium and magnesium ion mass concentration of 5 to 19 g/L; the Saudi oil and water system in the mine Within the range of a chemical degree of 50 to 200 g/L and a total calcium and magnesium ion mass concentration of 5 to 23 g/L, the interfacial tension is maintained at an ultra-low level, demonstrating excellent salt and calcium and magnesium resistance.

The patent applied by the Institute of Physics and Chemistry Technology of the Chinese Academy of Sciences uses the reaction of saturated cardanol short-chain alcohol solution and dialkyl amine to prepare saturated cardanol dialkyl amine, and then reacts with sodium chloroacetate or 3-chloro-2-hydroxypropanesulfonate Saturated cardanol betaine is prepared by reaction of sodium acid.

[Application and development prospects][1]

As a long-chain hydrocarbon-based natural phenolic substance, cardanol has broad application prospects in the field of surfactants and has attracted great attention from many scholars. Cardanol surfactant, as a type of biomass surfactant, has excellent emulsification, decontamination and other properties, and has excellent properties such as low toxicity and biodegradability. Under the premise of environmental protection and energy shortage, the development of cardanol surfactants will have more far-reaching significance.

[Reference materials]

[1] Ge Zan, Shi Liwen, Dai Yongchang, Hua Wengao, Liu Rong. Research progress on the synthesis of cardanol surfactants [J]. Daily Chemical Industry, 2017, 47(11): 645-650.

The emulsification performance of the binary system is 36 s, which is of great significance for reducing oil displacement costs and recovering retained crude oil. Xing Xinxin studied the interfacial properties of the synthesized cardanol betaine surfactants (C15SB-Ⅰ and C15SB-Ⅱ). The results showed that: C15SB-Ⅰ and C15SB-Ⅱ were at 0. 3 ~ 0. 5 g / L When , it can reduce the interfacial tension of Tuha and Saudi oil-water systems to ultra-low values (less than 10-3 mN/m); C15SB-Ⅰ has excellent temperature resistance and can The dynamic interfacial tension equilibrium values of Tuha and Saudi oil-water systems reach 4. 67×10-3 and 1. 23×10– 3 mN/m respectively; C15SB- Solution I can reduce the interfacial tension of the Tuha oil and water system and maintain an ultra-low value within the range of a salinity of 80 to 270 g/L and a total calcium and magnesium ion mass concentration of 5 to 19 g/L; the Saudi oil and water system in the mine Within the range of a chemical degree of 50 to 200 g/L and a total calcium and magnesium ion mass concentration of 5 to 23 g/L, the interfacial tension is maintained at an ultra-low level, demonstrating excellent salt and calcium and magnesium resistance.

The patent applied by the Institute of Physics and Chemistry Technology of the Chinese Academy of Sciences uses the reaction of saturated cardanol short-chain alcohol solution and dialkyl amine to prepare saturated cardanol dialkyl amine, and then reacts with sodium chloroacetate or 3-chloro-2-hydroxypropanesulfonate Saturated cardanol betaine is prepared by reaction of sodium acid.

[Application and development prospects][1]

As a long-chain hydrocarbon-based natural phenolic substance, cardanol has broad application prospects in the field of surfactants and has attracted great attention from many scholars. Cardanol surfactant, as a type of biomass surfactant, has excellent emulsification, decontamination and other properties, and has excellent properties such as low toxicity and biodegradability. Under the premise of environmental protection and energy shortage, the development of cardanol surfactants will have more far-reaching significance.

[Reference materials]

[1] Ge Zan, Shi Liwen, Dai Yongchang, Hua Wengao, Liu Rong. Research progress on the synthesis of cardanol surfactants [J]. Daily Chemical Industry, 2017, 47(11): 645-650.

微信扫一扫打赏

微信扫一扫打赏