[Overview]

The photoinitiator TPO is a highly efficient free radical (1) type photoinitiator that absorbs in a long wavelength range. Due to its wide absorption range, its effective absorption peak is 350-400nm, and the absorption peak reaches about 420nm. Its absorption peak is longer than that of conventional initiators. After illumination, it can generate two free radicals, benzoyl and phosphoryl. It can initiate polymerization, so the light curing speed is fast. It also has photobleaching effect, which is suitable for deep curing of thick films and non-yellowing properties of coatings. It has low volatility and is suitable for water-based applications. Mostly used in white systems, it can be used in UV curing coatings, printing inks, UV curing adhesives, optical fiber coatings, photoresists, photopolymerizing printing plates, stereolithographic resins, composite materials, dental fillings, etc.

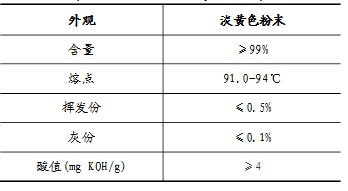

[Physical and chemical properties]

Characteristics: light yellow crystalline powder; melting point: 91-94°C, absorption wavelength: 273-370nm; light curing speed is fast.

Table 1 is the photoinitiator TPO product index table

[Features]

Due to its wide absorption range, its effective absorption peak is 350-400nm, and the absorption peak reaches about 420nm. Its absorption peak is longer than that of conventional initiators. After illumination, it can generate two benzoyl and phosphoryl groups. Free radicals can initiate polymerization, so the light curing speed is fast. It also has a photobleaching effect, which is suitable for deep curing of thick films and non-yellowing properties of coatings. It has low volatility and is suitable for water-based applications. Mostly used in white systems, it can be used in UV curing coatings, printing inks, UV curing adhesives, optical fiber coatings, photoresists, photopolymerizing printing plates, stereolithographic resins, composite materials, dental fillings, etc.

[Purpose]

It is a photoinitiator, mainly used in screen printing ink, lithographic printing ink, flexo printing ink, and wood coating. TPO can be fully cured on white or high titanium dioxide pigmented surfaces. It is widely used in various coatings. Its excellent absorption properties make it particularly suitable for screen printing inks, offset printing, flexo printing inks, and wood coatings. The coating does not yellow, has low post-polymerization effect and leaves no residue. Can also be used in clear coats, especially for products with low odor requirements. Used alone in unsaturated polyester containing styrene system, it has high initiating efficiency. For acrylate systems, especially colored systems, they usually need to be used in conjunction with amines or acrylamide, and combined with other photoinitiators to achieve complete curing of the system. It is especially suitable for low yellowing, white systems and thick film layers. of curing. Photoinitiator TPO is used in conjunction with MOB 240 or CBP 393 to improve curing efficiency. It is the best extraction solvent for petroleum aromatics equipment and is also used as a formylation reagent in the field of fine chemicals.

微信扫一扫打赏

微信扫一扫打赏