Background and overview[1]

Di-tert-butyl azidooxalic acid can be used as a pharmaceutical synthesis intermediate. If di-tert-butylazidooxalic acid is inhaled, move the patient to fresh air; if skin contact occurs, take off contaminated clothing, rinse the skin thoroughly with soap and water, and seek medical attention if you feel unwell; if contact with eyes , you should separate your eyelids, rinse with running water or saline, and seek medical attention immediately; if ingested, rinse your mouth immediately, do not induce vomiting, and seek medical attention immediately.

Preparation[1]

Di-tert-butyl azidooxalic acid is prepared as follows:

The specific steps are as follows: under ice bath conditions, drop a 50ml solution of hydrazine monohydrate (5.85g, 85%, 200mmol) into a 50ml methanol solution of BOC anhydride (48g, 220mmol) within 30 minutes, and the resulting mixed solution Stir at room temperature for 3 hours, spin dry the methanol, and add 250 ml of n-hexane. The resulting white solid is suction filtered and washed with n-hexane to obtain 19.34 g of white solid di-tert-butyl azide oxalic acid with a yield of 84%. 1H NMR (300MHz, CDCl3): δ = 6.60 (s, 2H), 1.47 (s, 9H); 13C NMR (50MHz, CDCl3) δ = 156.0, 84.1, 28.3.

Apply[1]

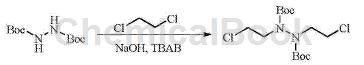

Di-tert-butyl azidooxalic acid can be used as a pharmaceutical synthesis intermediate. If the following reaction occurs:

The specific steps are as follows: di-tert-butyl azidooxalic acid (11.6g, 50mmol), 50ml sodium hydroxide aqueous solution (30%wt), 1,2-dichloroethane (100ml), catalytic amount of tetrabutyl Ammonium bromide (0.5g) was mixed. The mixture was heated at 55°C for 10 hours, cooled, and the organic phase was separated. The aqueous phase was extracted with dichloromethane. The organic phases were combined, dried over anhydrous sodium sulfate, spin-dried to dry the solvent, and column chromatographed (petroleum) Ether: ethyl acetate = 10:1) to obtain a colorless viscous liquid (13.8 g, yield 75%). 1H NMR (300MHz, CDCl3): δ=3.53–3.97(m,8H),1.49(m,18H).

Main reference materials

[1] CN201410570945.7 A complex containing hydrazine-type nitrogen and phosphorus ligands and its application in the catalytic hydrogenation of esters. Application date 20141023, Wuhan Kaitris Technology Co., Ltd.

微信扫一扫打赏

微信扫一扫打赏