Octabromoether is also known as tetrabromobisphenol A (2,3-dibromopropyl) ether. It is in the form of off-white powder with a molecular weight of 943.65. Off-white powder, relative density 2.17. Melting point 107~120℃. The theoretical bromine content is 67.7%. Soluble in dichloroethane, toluene, acetone, slightly soluble in water and methanol. The temperature at which mass loss is 5% is 325°C.

There are three synthesis methods for octabromoether:

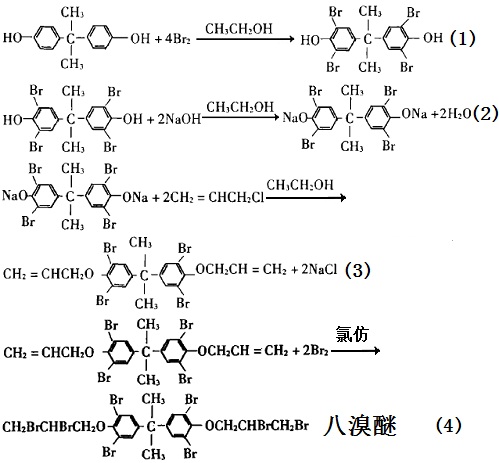

1. Synthesis of tetrabromobisphenol A: as shown in reaction formula (l), Put bisphenol A into a four-necked flask, add alcohol, stir, and add water. Weigh the bromine into the dropping funnel and slowly drip it into the flask while stirring. The color in the flask gradually becomes darker. When the bromine is dripped, the temperature of the entire process is controlled below 52°C. After continuing to stir for 20 minutes, slowly increase the temperature to 70°C and maintain it for 20 minutes. The color in the flask changes from red to yellow, and finally to milky white. Stop stirring, cool to room temperature, and separate using dropping funnel. Wash with 60℃ hot water until the pH value of the washing liquid reaches neutral. Weigh tetrabromobisphenol A and dry it in an oven at 120°C to obtain white powder.

2. Synthesis of tetrabromobisphenol A disallyl ether: As shown in reaction formula (2) and reaction formula (3), put tetrabromobisphenol A into a four-necked flask and take Add alcohol, stir, and wait until completely dissolved. Weigh the caustic soda, dissolve it completely with water, put it into a dropping funnel, and slowly add it dropwise. The color in the flask will turn red and then light, which will take about 25 minutes. The entire process should be kept below 45°C for another 15 minutes. Take the chloropropene and put it into the dropping funnel, slowly drip it in, and maintain the temperature at about 40°C. The whole process takes about 30 minutes, and then slowly raise the temperature to 55°C. Wait for the chlorpropene to reflux for 20 minutes, cool to room temperature, and wash with water, that is, available.

3. Synthesis of octabromoether: As shown in reaction formula (4), add tetrabromobisphenol A disallyl ether into chloroform. After it is completely dissolved, add bromine dropwise and continue. Keep it for 30 minutes, then wash it three times with saturated sodium sulfite solution to remove unreacted red free bromine in the solution. After it turns white, add a small amount of water and stir. Stop stirring, separate chloroform from water, remove the water layer, drop alcohol into chloroform, extract, and octabromoether precipitates.

微信扫一扫打赏

微信扫一扫打赏