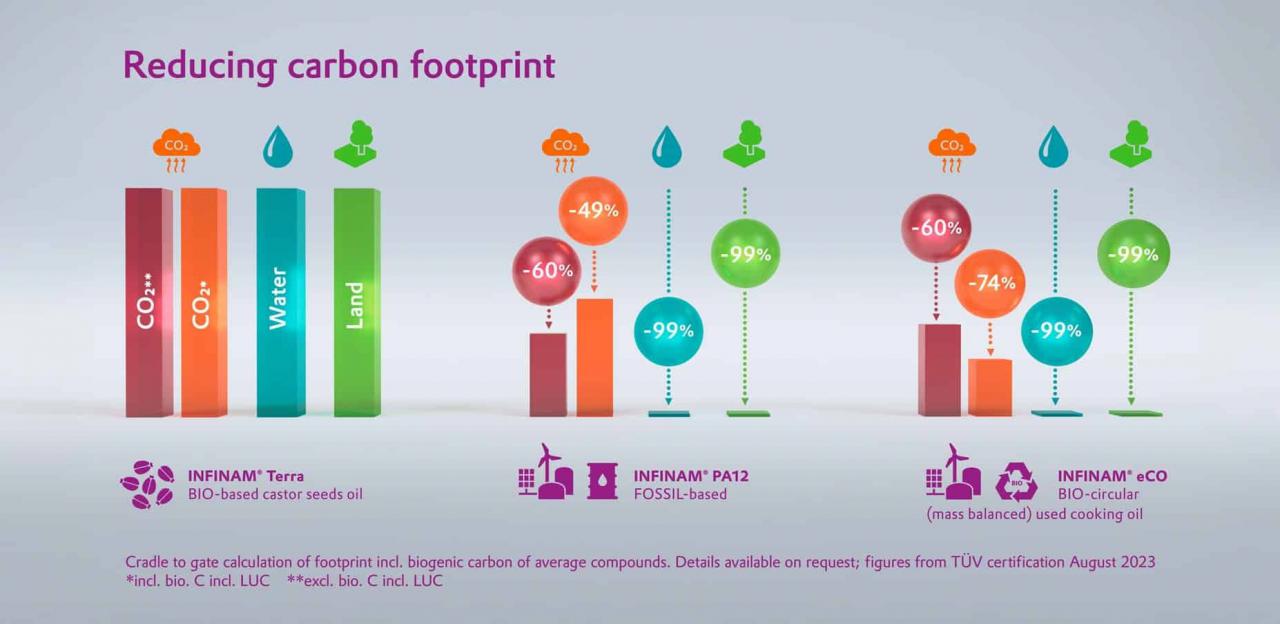

● Biological recycling raw materials are made from waste cooking oil and can 100% replace fossil raw materials.

● 74% less CO2 emissions compared to Evonik’s castor oil-based polyamides

● Promote the development of circular economy in the field of 3D printing

Evonik, the world’s leading specialty chemicals company, launches new INFINAM® eCO polyamide 12 (PA12) powder. INFINAM® eCO

PA12 is based on the mass balance method and is made from waste cooking oil, which can 100% replace fossil raw materials. With Evonik INFINAM®

Compared with Terra development grade castor oil-based polyamide, its CO2 emissions are reduced by 74%. Since the launch of a new series of PA12 low-carbon footprint products at the end of 2022, Evonik has continued to explore material recycling and comprehensively improve the sustainable benefits of the PA12 powder product portfolio, thereby promoting sustainable development in the additive manufacturing field.

Biological recycling raw materials are the fundamental starting point for realizing circular economy

True recycling begins with biological recycling of raw materials. Currently, the global catering industry produces more than 15 million tons of waste cooking oil every year. In addition to being processed into products such as biodiesel, these waste cooking oils can also be used in the manufacture of chemical raw materials.

Dominic, Head of Innovation Growth Area for Additive Manufacturing at Evonik

Störkle said: “Achieving true circularity is the key to future success. As a leading manufacturer of polymer materials for 3D printing, Evonik has developed a new PA12 powder formulation that can promote circularity in additive manufacturing. With INFINAM®

With the launch of eCO PA12, we will transcend chemical boundaries and gradually realize a closed loop of material recycling, thereby meeting market expectations and creating a better future. ”

INFINAM® eCO

PA12 not only uses renewable energy and biological recycling raw materials, which can reduce the carbon footprint of the product, but has also been proven to achieve a 100% reuse rate, further improving the sustainable benefits of the product. After multiple printing cycles, the reuse rate of old powder and new powder can still reach 70/30. In addition, INFINAM®

eCO PA12 has excellent processing properties and maintains stable mechanical properties, making it an ideal choice for manufacturing 3D printed parts.

Comprehensive“circulation”Practice

Evonik INFINAM® eCO PA12 is based on the following four principles of circular plastics:

• reuse

• Reduce

• Renewable

• Recycle

In addition to increasing production efficiency or material reuse, Evonik’s circular practices also include the use of INFINAM® eCO

The entire life cycle of PA12 is evaluated and continuously improved; while paying attention to the carbon footprint, it also pays attention to other important factors such as water consumption and land use. By using renewable energy and renewable/recyclable raw materials for production, Evonik significantly improves the overall ecological balance of the material. In the future, Evonik will continue to explore new recycling opportunities for PA12 powder to achieve a completely closed-loop material cycle.

INFINAM® eCO

In the PA12 grade, “eCO” means that the product is based on the mass balance method and uses renewable/recyclable raw materials, thereby reducing greenhouse gas emissions. The mass balance method can help companies immediately reduce the carbon dioxide emissions of existing products.

Evonik’s Additive Manufacturing Innovation Growth Area brings together the Group’s internal 3D printing technology expertise and focuses on developing and manufacturing high-performance polymers suitable for mainstream 3D printing processes, thus promoting the large-scale application of 3D printing technology throughout the entire value chain. To this end, Evonik created the INFINAM® brand to promote and sell the related product portfolio.

微信扫一扫打赏

微信扫一扫打赏