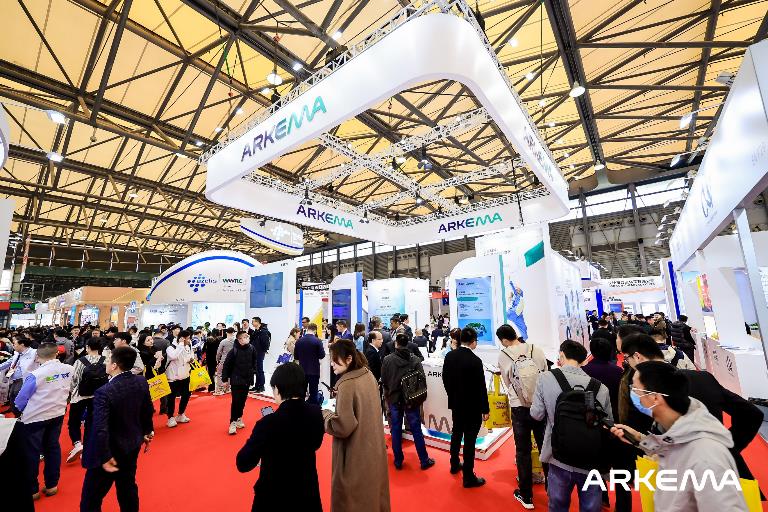

Arkema, the world’s leading manufacturer of specialty materials, will appear at the 2023 China International Coatings Exhibition from November 15th to 17th to showcase its more sustainable solutions and innovations in the field of coatings. The booth is located in Shanghai New International Expo Center E4.F21.

Arkema brings innovative sustainable solutions to China International Coatings Exhibition 2023

“Not long ago, we established our ambitious goals for 2028 and further clarified our vision: to provide innovative high-performance materials and build a more sustainable world.” Ms. Zhang Xiaoyu, President of Arkema Greater China, said, “The Chinese market is in Arkema occupies an important position in the Group. We will fully support our customers and partners to achieve the goals of sustainable growth and sustainable development. Arkema China will bring together strong professional knowledge and a wide range of unique technology portfolio, and actively explore research and development The potential of implementing sustainable development in all aspects of the production process can help reduce the carbon footprint and promote the sustainable development process.”

As one of the Arkema Group’s three complementary, strong and highly innovative Specialty Materials business units, Coating Solutions is at the forefront of the market with its high-performance innovative materials and an unparalleled portfolio of cutting-edge technologies. At the Capital Markets Day held on September 27, Arkema Group announced its ambitious goals for 2028, further clarifying the development direction of taking sustainable development as the core of its strategy and accelerating organic growth in the field of high-performance materials and sustainable solutions. At the same time, the group will also use the near-term science-based carbon targets (SBTi) to organize its 1.5°C

The recognition of emission reduction pathways will further strengthen its decarbonization initiatives towards the ambitious goal of net-zero carbon emissions by 2050.

New sustainable products

At this Chinacoat, Arkema will showcase its new sustainable products for the industry and provide comprehensive solutions for emerging markets, such as housing energy conservation, more circular homes, community health and well-being, and decarbonization of the built environment.

Adhering to the group’s sustainable development strategy, Arkema’s “Coating Solutions” aims to accelerate the green transformation of the coatings value chain from four aspects, namely phasing out harmful substances, developing bio-based raw materials, developing more efficient and sustainable technologies, Promote the transformation of applied processes towards improving industrial and energy efficiency.

Arkema offers new sustainable products to industry

In addition to the exhibition, Arkema’s experts will also present their research results at this Chinacoat.

“Arkema, a partner for comprehensive and sustainable development”

Han Zhigang, Arkema China Technical Service Manager

Yohann TRANG, Global Commercial Manager Rheology and Specialty Additives at Arkema (Coatings, Inks, Adhesives and Sealants)

November 16 (Thursday) 11:20-12:00 Conference Room: M25

Sustainability is a key issue in the coatings industry. Arkema has set ambitious goals to reduce its carbon footprint. Arkema’s experts will present the latest bio-based or low-carbon footprint resins, HEUR thickeners, PAA dispersants, HASE thickeners, polyurethanes and polyamide products, all with high-performance properties that will empower partners Join us in achieving the Sustainable Development Goals.

Arkema also develops bioacrylic materials in various regions. These products utilize a “mass balance” approach and are produced from renewable or recycled raw materials. In 2022, the Group will open a new business in Carling, France

The factory has obtained the European International Sustainability and Carbon Certification-PLUS (ISCC+), and this certification process will be expanded to China in the first quarter of 2024. These results are important milestones in the transition of Arkema Group and its Coating Solutions business unit to a more renewable and lower-carbon economy.

Leading portfolio of lower VOC and lower carbon coating technologies

The company showcased its leading portfolio of high-performance and sustainable materials, including UV/LED, water-based, high-solids technologies and high-performance polymer solutions.

Arkema showcases its leading portfolio of high-performance and sustainable materials

• Water-based systems

Water-based systems are one of Arkema’s key low-volatility (VOC) technologies. The product portfolio includes a wide range of water-based resins, additives and long-lasting weather-resistant PVDF emulsions. Arkema has world-renowned water-based resin solutions, including Encor®, a styrene-acrylic emulsion designed specifically for industrial coatings.

2436 and pure acrylic emulsion Encor® 2787 CS for decorative coatings, Synaqua® bio-based waterborne alkyd range, and Encor® and Kynar for “cool roof” technology

Aquatec® lotion, etc., can save up to 30% of air conditioning energy. The water-based additive series focuses on the launch of the Coapur™ series of polyurethane thickeners based on bio-based materials and Ecodis™ based on the MB platform.

MB and Rheotech™ MB series dispersants and thickeners, etc., can be widely used in construction and building materials, industry, adhesives and other fields, providing high-performance and sustainable water-based products.

• UV/LED/EB curing system

Arkema’s UV/LED/EB light curing products offer low VOC

and energy-saving and environmentally friendly formulation solutions, and help improve the mechanical properties and weather resistance of coatings to maintain excellent appearance. Sartomer® by Arkema

Special acrylic resins are widely used in UV/LED/EB curing systems, and the rich and diverse product categories provide strong support for more flexible formula design. Sartomer®

A series of acrylic prepolymers and monomers are widely used in 3C coatings, automotive interior and exterior coatings, UV inkjet, solder mask ink, optical film coating, photoresist, offset ink and other fields. Arkema Special UV/LED

The expansion of cured resin production in China will support the Group in developing more sustainable solutions for rapidly growing application areas in the Asian market, such as electronic products driven by 5G technology and cutting-edge technologies in the field of renewable energy.

• Powder systems

Arkema’s powder system is a more sustainable technology with almost zero organic compounds (VOCs) and harmful gases (HAPs), no solvents, and no waste. It covers most technologies currently on the market, including thermal solidifying and thermoplastic systems as well as surface modifiers and leveling agents. Powder system products are also widely used in conventional industry, home appliance manufacturing, home decoration and aviation fields. Among Arkema’s many products,

Orgasol® nylon ultra-fine powder has a uniform spherical appearance and porous structure, which can reduce the gloss of the paint film and improve the wear resistance. Arkema also offers Reafree®

Powder coating resin, ultra-durable solution for low-carbon applications through low-temperature cure technology.

• High solids system

In terms of high-solid coating systems, Arkema has always been committed to higher-performance, low-VOC solutions and has developed a series of resin and additive products to solve various challenges brought by new systems. Among them, Synocure®

854 BA 80 MY High solids hydroxyl acrylic resin with low NCO requirements and excellent weatherability for economical heavy-duty corrosion-resistant topcoats with ultra-low VOC requirements; Crayvallac®

Optima polyamide wax powder, with a bio-based content of 92%, has excellent anti-settling and anti-sag properties, storage stability, and wide applicability, especially suitable for high-solid systems.

微信扫一扫打赏

微信扫一扫打赏