For BASF, sustainable development means combining economic success, social responsibility and environmental protection. In 2021, BASF launched a climate neutrality roadmap, announcing the goal of achieving net zero global carbon dioxide emissions by 2050. Since then, many bases and products around the world have successively obtained the International Sustainability and Carbon Certification (ISCC).

What is ISCC?

ISCC is a sustainable development certification system covering the entire supply chain of biomass raw materials and renewable energy. It is an internationally recognized certification scheme for mass balance methods. ISCCPLUS acts as a sustainability certification for plastics, chemicals, food and feed and biofuels outside the EU and UK.

BASF has obtained multiple ISCCPLUS certifications

Recently, BASF announced that specific grades of plastic additives in its brand VALERAS® have obtained the International Sustainability and Carbon (ISCC) PLUS certification, allowing customers to choose more sustainable antioxidants without compromising performance. VALERAS™ covers sustainable solutions in the plastic additives portfolio. With VALERAS™, BASF can provide valuable sustainable solutions for the plastics industry, thereby achieving the goal of saving fossil resources and reducing costs for customers.

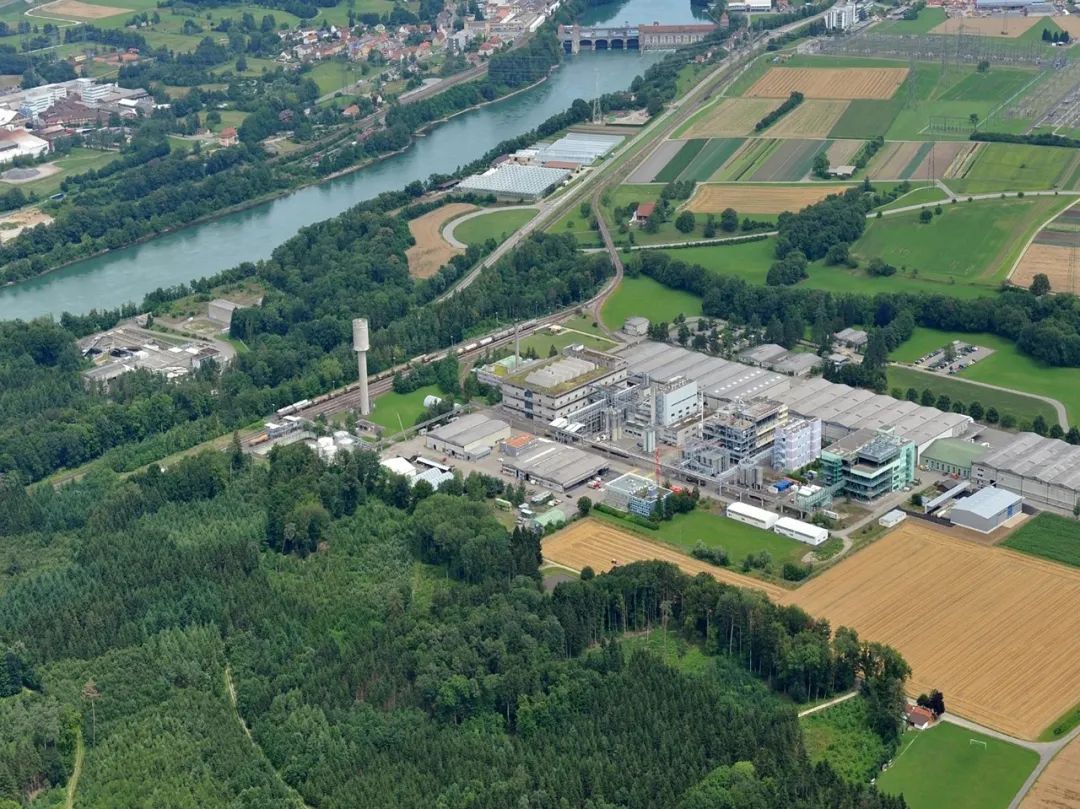

BASF Base in Kaisten, Switzerland

BASF’s McIntosh site in Alabama, USA

Specific plastic additive products certified by ISCCPLUS are being pilot-produced at BASF’s production sites in Switzerland and the United States

In March of this year, BASF’s monomer business unit released a sustainable development roadmap, announcing that it will expand its product portfolio with low carbon footprints, and committing to provide circular solutions for each major series of products by 2025. BASF’s Monomers business unit supplies basic chemicals for many industries, from food packaging, textiles, the automotive or construction sectors to wood adhesives and many more. At present, this business unit has obtained the first ISCC+ certification in the Asia-Pacific region. Its main base and more than 200 products have obtained RedCert2 or ISCC+ certification. Related products include adipic acid, polyamide (PA) 6.6, MDI (diphenyl methyl methane diisocyanate) and TDI (toluene diisocyanate).

BASF’s polyol and polyurethane (PU) system plant in Nansha, Guangzhou

Last year, BASF Performance Materials received ISCC+ certification for its polyol and polyurethane (PU) system plant in Guangzhou, China. This demonstrates BASF’s ability to produce certified low carbon mass balance polyurethane products. It paves the way for footwear manufacturers using BASF’s Elastopan® polyurethane to commercially produce sustainable footwear. In addition, the engineering plastics mixing plant located in Pasir Gudang, Malaysia has also obtained ISCC+ and REDcert² international certification. BASF Performance Materials is mainly active in the four major fields of transportation, construction, industrial applications and consumer goods.

BASF’s engineering plastics compounding plant in Pasir Gudang, Malaysia is now certified by the International Sustainability and Carbon Certification (ISCC+) and REDcert²

What does it mean to obtain the high-demand ISCC certification?

BASF is committed to achieving the respective sustainability goals of its customers. Obtaining ISCC certification demonstrates BASF’s ability to produce low-carbon footprint products through the mass balance method, reduce greenhouse gas emissions, and promote sustainable development of the industry’s value chain.

BASF’s mass balance method is responsible for this certification

The mass balance method uses renewable raw materials as raw materials for the production of basic chemicals in order to save limited fossil resources.

微信扫一扫打赏

微信扫一扫打赏