Recently, Beijing Aerospace Petrochemical Technology and Equipment Engineering Co., Ltd. (hereinafter referred to as Beijing Aerospace Petrochemical), a wholly-owned subsidiary of Beijing Aerospace Propulsion Institute (BAPI), the Sixth Research Institute of China Aerospace Science and Technology Corporation, and the world’s leading Saudi Basic Industries Corporation (SABIC), a leader in the chemical industry, held a signing ceremony in Beijing, signing an agreement for SABIC to obtain Beijing Aerospace Petrochemical Aerospace Pyrolysis SHCP® technology.

At the signing ceremony, Zhang Yanjun, deputy director and project leader of Beijing Institute of Aerospace Propulsion, introduced in detail the technical advantages and commercial application progress of aerospace pyrolysis SHCP® technology in the field of chemical recycling of waste plastics.

Amelie Hu, General Manager of the Strategic Development Department of the Greater China Region and Olivier Gu, Director of the Science and Technology Innovation Department of the Asia Pacific Region, attended the event on behalf of SABIC.

Guise highly affirmed the advantages of aerospace pyrolysis SHCP® technology over other technologies. For example, the coke produced can be burned as a fuel source in the process, making it possible to scale up with high heat transfer efficiency and low waste.

The successful signing of this contract will further accelerate the application of aerospace pyrolysis SHCP® technology in the engineering field, and will also help Saudi Basic Industries Corporation’s global layout of the circular economy industry. The cooperation between the two parties will play an important role in promoting the development of the global waste plastic chemical recycling field and contribute to the global circular economy.

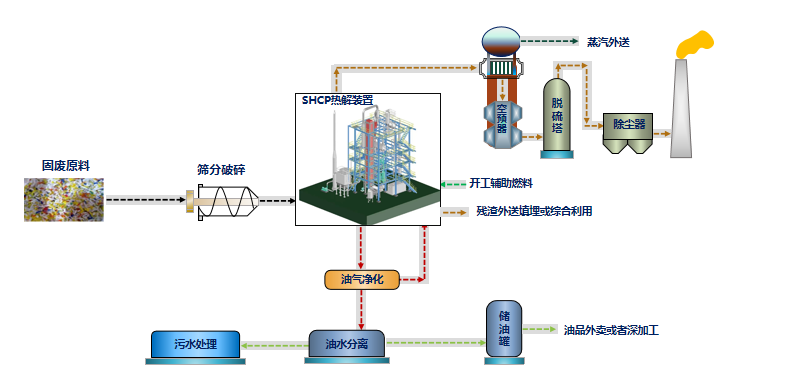

The picture shows the aerospace pyrolysis SHCP® technology demonstration device

Since 2016, the Beijing Institute of Aerospace Propulsion has independently developed SHCP®, a waste plastic chemical recycling technology for mechanical fluidized pyrolysis of solid heat carrier circulation, relying on advanced technologies such as rocket engine heat transfer, sealing, and combustion, which can realize different types of low-cost waste plastics. High value-added utilization of residual value waste plastics.

In July 2018, a 10-ton-per-day pilot plant was built in Bazhou, Hebei, which realized the “full process, self-closed loop, full load” and The goal of 168 hours of continuous operation.

This technology solves the problems that organic solid waste pyrolysis technology is difficult to achieve large-scale, continuous, easy to coke, etc., and has five major technical advantages:

① Wide adaptability of raw materials.

It can eat “coarse grains”, can process all kinds of mixed plastics, does not need to be sorted and cleaned, and does not produce secondary pollution. It can be expanded to be applied to various organic solid wastes such as oil sludge, sludge, and domestic garbage.

②Excellent environmental indicators.

Pyrolysis high-temperature anaerobic operation plus purification before fuel, in principle, eliminates the generation of dioxins, and the pyrolysis carbon is completely harmless after burning again.

③ Avoid pyrolysis and coking.

The use of solid heat carrier and organic solid waste to directly contact and grind each other realizes the self-cleaning effect of the reactor and ensures that the plastic will not coke when heated.

④ Large-scale production can be realized, and the economy is good.

The direct contact between solid heat carrier and organic solid waste has a fast heating rate, which can realize large-scale production, and pyrolysis carbon pyrolysis gas is used as fuel to realize self-closed loop, which is economical.

⑤ Obtain the best oil recovery rate.

The optimal pyrolysis temperature can be adjusted according to the composition of raw materials, and the heating speed is fast, which avoids the secondary decomposition of pyrolysis oil.

Main application scenarios:

①Waste plastic oil treatment field

It can process domestic waste sorting waste plastics, industrial dismantling waste plastics, paper mill waste plastics, agricultural mulch, etc.

②Deep disposal of industrial sludge

It can handle oilfield sludge, tank bottom sludge, oil-based drilling cuttings, oily contaminants, and refining and chemical sludge, etc.

③Pyrolysis and resource utilization of domestic waste

It can be used for fully quantified resource utilization of domestic waste in small and medium-sized cities.

④Other organic solid waste treatment

It can process waste tires, biomass, municipal sludge and other solid wastes.

微信扫一扫打赏

微信扫一扫打赏