On May 10, the signing ceremony of the general contract for the new material integrated propylene value chain project of Nanjing Chengzhi Yongqing Energy Technology Co., Ltd. was held in Nanjing, Jiangsu. Qin Baojian, Vice President of Chengzhi Co., Ltd., Secretary of the Party Committee and Chairman of Nanjing Chengzhi Clean Energy Co., Ltd., Tan Bin, Assistant President of Chengzhi Co., Ltd., Chairman of Nanjing Chengzhi Yongqing Energy Technology Co., Ltd., and Zheng Zheng, Deputy General Manager of Chengda Company Lan and others attended the signing ceremony.

On April 3, Chengzhi Co., Ltd. announced that in order to further expand the development space in the field of new chemical materials, the company plans to invest in the construction of new materials in Nanjing Jiangbei New District New Material Science and Technology Park through its wholly-owned subsidiary Nanjing Chengzhi Yongqing Energy Technology Co., Ltd. The integrated propylene value chain project has a total investment of 1.05 billion yuan.

Project Name: New Material Integrated Propylene Value Chain Project

Implementation address: This project is located at No. 78, Zhaoqiaohe Road, New Material Science and Technology Park, Jiangbei New District, Nanjing (in Chengzhi Yongqing factory area)

Construction content: The construction scope of this project includes 250,000 tons/year octanol production equipment, storage and transportation engineering (including the external pipe of the equipment, tank farm and loading system), public works water supply and drainage and other auxiliary facilities. ,

Investment amount: The estimated total investment amount of this project is 1.05 billion yuan.

Funding source: Self-owned and self-raised funds.

Project progress: The estimated construction period of this project is 18 months, and it is currently in the preliminary approval stage of the project.

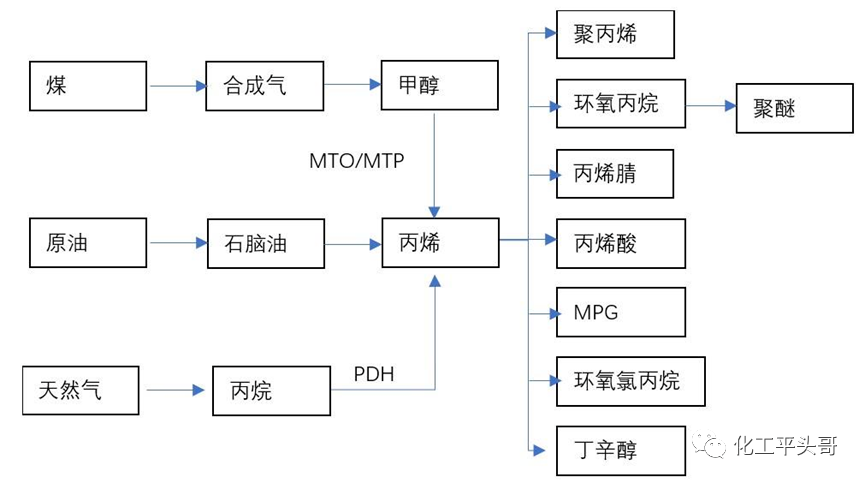

Propylene Value Chain

Propylene is known as the most important basic raw material for the extension of China’s chemical industry chain. With the rapid development of the PDH industry in recent years, propylene produced by propane dehydrogenation has become the focus of attention in the propylene industry chain.

Industrial chain one: PDH value chain

In the PDH industry chain, the main raw material is propane. Compared with the propane separated by the gas separation device, the purity of propane required by PDH is higher. Based on the calculation of 1.18 tons of propane to produce 1 ton of propylene, and the processing cost is 1,200 yuan/ton, the price of propane accounts for a larger proportion of the cost of producing propylene from PDH. According to the calculations in the past few years, the average ratio of propane price to the cost of propylene has reached More than 77%. Therefore, the price of propane in the PDH industry chain has the greatest impact on the PDH industry chain.

Industrial Chain II: Naphtha Cracking to Propylene Value Chain

Naphtha cracking is used to produce ethylene and propylene. Due to the large number of products from the cracking unit, it is generally accepted in the industry that ethylene and propylene are calculated as equal costs. Therefore, the cost of naphtha cracking to produce propylene can also be regarded as equivalent to the cost of ethylene. For the cost of producing propylene from naphtha cracking, the Sinopec system has its own algorithm, the PetroChina system also has its own algorithm, and the international market has an algorithm for the international market. In addition, within the main enterprise system, there are different calculation formulas for whether ethylene is used as mutual supply or transfer among enterprises.

Industrial Chain III: Coal to Propylene Value Chain

For coal-to-propylene, collectively referred to as coal-to-olefins in the industry, it is a process in which coal is processed to produce synthesis gas, reproduced to methanol, and finally to produce ethylene and propylene.

Industrial Chain Four: Polypropylene Value Chain

The largest consumer group downstream of propylene is polypropylene, accounting for more than 73% of propylene consumption, followed by the production of butanol, propylene oxide, and acrylonitrile. Polypropylene carries a large amount of propylene consumption in China, and the downstream of PDH devices mostly supports the production of polypropylene.

In recent years, with changes in cost and market supply and demand, the value chain of the propylene industry has been constantly changing. Changes in the value chain have brought opportunities to the market, as well as challenges. my country’s propylene industry has experienced the peak of capacity expansion from 2014 to 2016, and after a short fall in 2017, the new production capacity in 2019 hit a record high, reaching 5.86 million tons per year. With the commissioning of new projects, it is estimated that the annual production capacity of propylene in my country will reach 52 million tons by 2023. However, the growth rate of propylene demand is lower than the growth rate of production capacity, and we need to be alert to the risk of overcapacity.

微信扫一扫打赏

微信扫一扫打赏