ETFE film has good application prospects and industry technical barriers are high

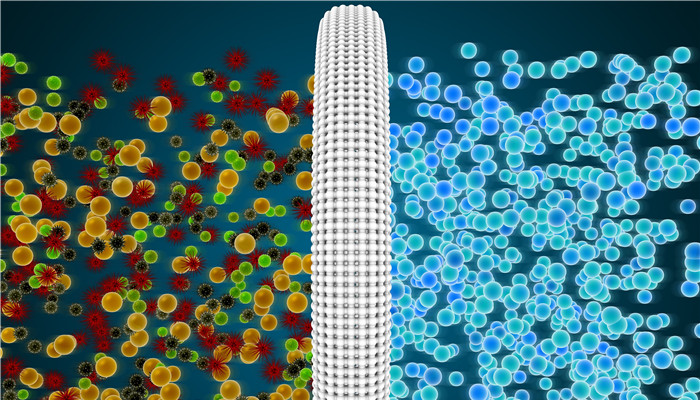

ETFE film, also known as ethylene-tetrafluoroethylene copolymer film and soft glass, refers to a film with ethylene-tetrafluoroethylene copolymer as the main component. ETFE film has the advantages of strong anti-fouling ability, recyclability, strong temperature resistance, high light transmittance, and easy cleaning. It is widely used in construction, photovoltaic power generation, semiconductor and other fields. According to different structures, ETFE films can be divided into double-layer air pillow films and single-layer ETFE films.

Ethylene-tetrafluoroethylene copolymer (ETFE) is the main component of ETFE film and is a melt-processable fluoroplastic. ETFE has the advantages of strong chemical resistance, good processability and creep resistance, and is widely used in the fields of coatings, wires and cables, and automobile manufacturing. Due to factors such as high technical barriers, my country’s ETFE has long been dependent on imports. In recent years, as the independent research and development capabilities of local companies have continued to improve, my country’s ETFE localization process has continued to accelerate, which will provide favorable conditions for the development of the ETFE film industry.

According to the “2023-2028 China ETFE film (ethylene-tetrafluoroethylene copolymer film) industry market in-depth research and development prospect forecast report strong>》 shows that from the perspective of product segmentation, single-layer ETFE membranes mostly adopt a small-span single-layer structure, with an appearance similar to glass and a lighter weight; double-layer air pillow membranes adopt an inner and outer two-layer membrane structure. Composed of multiple air bags. Compared with single-layer ETFE film, double-layer air pillow film has the advantages of good impact resistance, good thermal insulation and sound insulation, and is expected to become a mainstream product in the ETFE film market in the future. In terms of market price, due to the difficulty in producing double-layer air pillow membranes and the extremely high equipment requirements, the price is relatively high.

ETFE film has excellent performance and can be used in construction, photovoltaic power generation, semiconductor and other fields. In the field of construction, ETFE films are extremely strong and are expected to be widely used in modern buildings instead of glass curtain walls in the future. The roofing material of the National Swimming Center’s “Water Cube” is made of ETFE films; in the field of photovoltaic power generation, ETFE films can be used Production of flexible solar cell covers. In the future, with in-depth research and technological advancement, the application scope of ETFE films will be further expanded.

There are only a small number of companies with ETFE film production capabilities in the world, and the United States and Japan dominate the market. my country’s leading ETFE film companies include Zhejiang Juhua Co., Ltd. and Shandong Dongyue Group. At present, Juhua Co., Ltd. has achieved large-scale production of ETFE architectural membranes through cooperation with overseas companies and the introduction of advanced production technology.

Industry analysts said that ETFE films are widely used and as the prosperity of the photovoltaic industry continues to increase, its market demand will continue to grow. As a subdivided product of ETFE film, double-layer air pillow film has excellent performance and broad prospects for industry development. In terms of market competition, the ETFE film industry has high technical barriers, and overseas companies dominate the global market. As local companies continue to improve their independent research and development capabilities, the localization process of my country’s ETFE films will further accelerate.

微信扫一扫打赏

微信扫一扫打赏