The current market size of bulk amorphous alloys is small, but its development speed is accelerating.

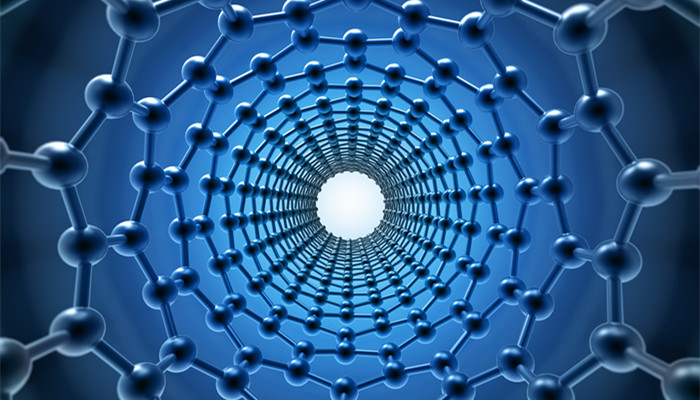

Amorphous alloys are produced by rapid solidification of alloys. There are no internal defects such as grains, grain boundaries, and dislocations. They have excellent physical and chemical properties and have the characteristics of excellent magnetism, high resistivity, high strength, and high hardness. Bulk amorphous alloy is a type of amorphous alloy product with excellent mechanical properties and outstanding high strength (up to 6GPa or more).

According to the “In-depth Market Research and Development Prospects Forecast Report of China’s Bulk Amorphous Alloy Industry from 2022 to 2027” released by the Industrial Research Center It shows that amorphous alloys need to be cooled and solidified at an extremely fast speed when preparing. In order to meet this requirement, at least one dimension must be extremely small to dissipate heat quickly. Therefore, its product forms are mainly strips and filaments. , powder, etc. Moreover, amorphous alloys have poor room temperature plasticity and are difficult to process. Affected by the above two factors, bulk amorphous alloys are difficult to produce and process, and their large-scale mass production and application are limited.

At present, the main types of bulk amorphous alloy products that have been developed include iron-based, magnesium-based, lanthanum-based, zirconium-based, palladium-based, titanium-based, cobalt-based, neodymium-iron-based, praseodymium-iron-based, samarium-iron-based, etc. Bulk amorphous alloys can be used as structural materials, connecting materials, tool materials, mold materials, corrosion-resistant materials, wear-resistant materials, impact-resistant materials, soft magnetic materials, magnetostrictive materials, etc., and are widely used in consumer electronics and medical equipment , aerospace and other fields, with its high strength advantages, it is extremely competitive in the aerospace market.

There are two main methods for preparing bulk amorphous alloys: direct solidification method and powder solidification method. Direct solidification methods mainly include water quenching method, copper mold casting method, high-pressure casting method, spray casting-suction casting method, etc.; powder consolidation methods mainly include hot pressing method, hot extrusion method, discharge plasma sintering method, etc. The direct solidification method uses alloy melt to prepare blocks, and the powder consolidation method uses amorphous alloy powder to prepare blocks. In comparison, the powder consolidation method has relatively low process difficulty and can prepare large-sized and complex-shaped bulk amorphous alloys, which has great development potential.

After continuous development, my country’s amorphous alloy powder preparation technology is now mature and output continues to grow, paving the way for the development of the bulk amorphous alloy industry. Against this background, my country’s bulk amorphous alloy production technology is becoming mature. my country is a major producer of electronic products. New consumer electronics products are constantly emerging, and existing product upgrades are accelerating, driving the demand for bulk amorphous alloys. At the same time, it is also constantly promoting the progress of the bulk amorphous alloy industry in the direction of high quality.

Industry analysts said that in the global market, strip is the mainstream amorphous alloy product. The production and application scale of bulk amorphous alloys is small. In order to promote the rapid development of the industry, its technical research is still in depth. In order to achieve rapid processing and forming of bulk amorphous alloys at room temperature, in 2020, Shenzhen University cooperated with other domestic universities and research institutes to develop a fast, simple, low-cost, multi-system and universal amorphous alloy forming method – ultrasonic plastic forming. (UPF). The emergence of new technologies will help promote the expansion of my country’s bulk amorphous alloy market.

微信扫一扫打赏

微信扫一扫打赏