High technical barriers: The global electroplating solution market for advanced packaging is monopolized by foreign brands

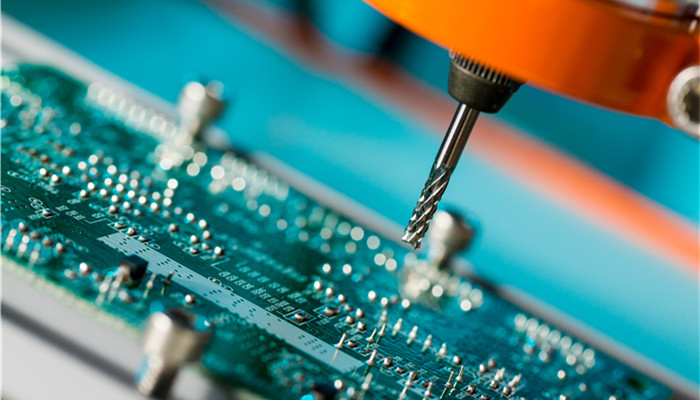

The electroplating solution is mainly composed of main salt, conductive agent, complexing agent and various electroplating additives. It can expand the cathode current density range of the metal, improve the appearance of the coating, and increase the anti-oxidation stability of the solution. It is one of the core materials in the semiconductor manufacturing process. one.

The electroplating solution formula system is complex and difficult to develop. The effect of electroplating is determined by the quality, ratio, and chemical properties of each component, as well as the electroplating process parameters (temperature, current density, electroplating time, etc.). In the process of developing the electroplating solution formula, dozens of organic compounds need to be screened to select suitable additives, and a large number of experiments are required to determine the types and ratios of different components and other types of additives. In addition, when developing electroplating solution formulas, companies also need to fully consider factors such as application processes, raw material costs, supply security, and environmental protection trends. Therefore, there are many testing projects for electroplating solutions and the development and testing cycle is long.

Electroplating solutions belong to the fields of wet chemicals and photoresist. These two fields are strategic emerging industries supported and developed by the country. In recent years, the country has issued a number of policies to encourage the development of the industry. The “Fourteenth Five-Year Plan for National Economic and Social Development of the People’s Republic of China and the Outline of Long-term Goals for 2035” proposes to accelerate key technological breakthroughs in high-performance resins such as metallocene polyethylene and high-purity electronic materials such as photoresist for integrated circuits. The “Guiding Opinions on Expanding Investment in Strategic Emerging Industries to Cultivate and Strengthen New Growth Points and Growth Pole (2020)” points out that accelerating the strengths and weaknesses of the new materials industry and accelerating the development of photoresists, high-purity targets, high-temperature alloys, high-performance fiber materials, Breakthroughs have been achieved in the fields of high-strength and high-conductivity heat-resistant materials, corrosion-resistant materials, large-size silicon wafers, and electronic packaging materials. The “Guidance Catalog for Industrial Structural Adjustment (2019 Edition)” includes materials for electronic products such as semiconductors in the encouraged category. The continuous introduction of favorable policies has provided strong support and a good environment for the development of the electroplating solution industry, and has promoted the rapid growth of my country’s electroplating solution market in recent years.

Industrial Research Center released “China Electroplating 2022-2026 Liquid Industry Market Monitoring and Future Development Prospects Research Report” pointed out that due to the long formula development cycle and high technical barriers, the global electroplating liquid market for advanced packaging is dominated by companies from developed countries such as Europe, the United States, and Japan. status, the main suppliers include DuPont of the United States, JSR of Japan, TOK of Japan, Merck of Germany, etc. There is a big gap between my country’s electroplating solution companies and international leading companies in terms of production scale and product quality. Domestic electroplating solution companies with larger scales and higher reputations mainly include Shanghai Xinyang Semiconductor Materials Co., Ltd., Guangzhou Sanfu New Material Technology Co., Ltd., Jiangsu Aisen Semiconductor Materials Co., Ltd., etc.

微信扫一扫打赏

微信扫一扫打赏