Display the product grades of Biomass Balance Certification (BMB), including Ultramid® polyamide (PA), Ultraform® polyoxymethylene (POM), polyether polyol Lupraphen, Elastopan® Polyurethane (PU), Elastollan® Thermoplastic Polyurethane (TPU)

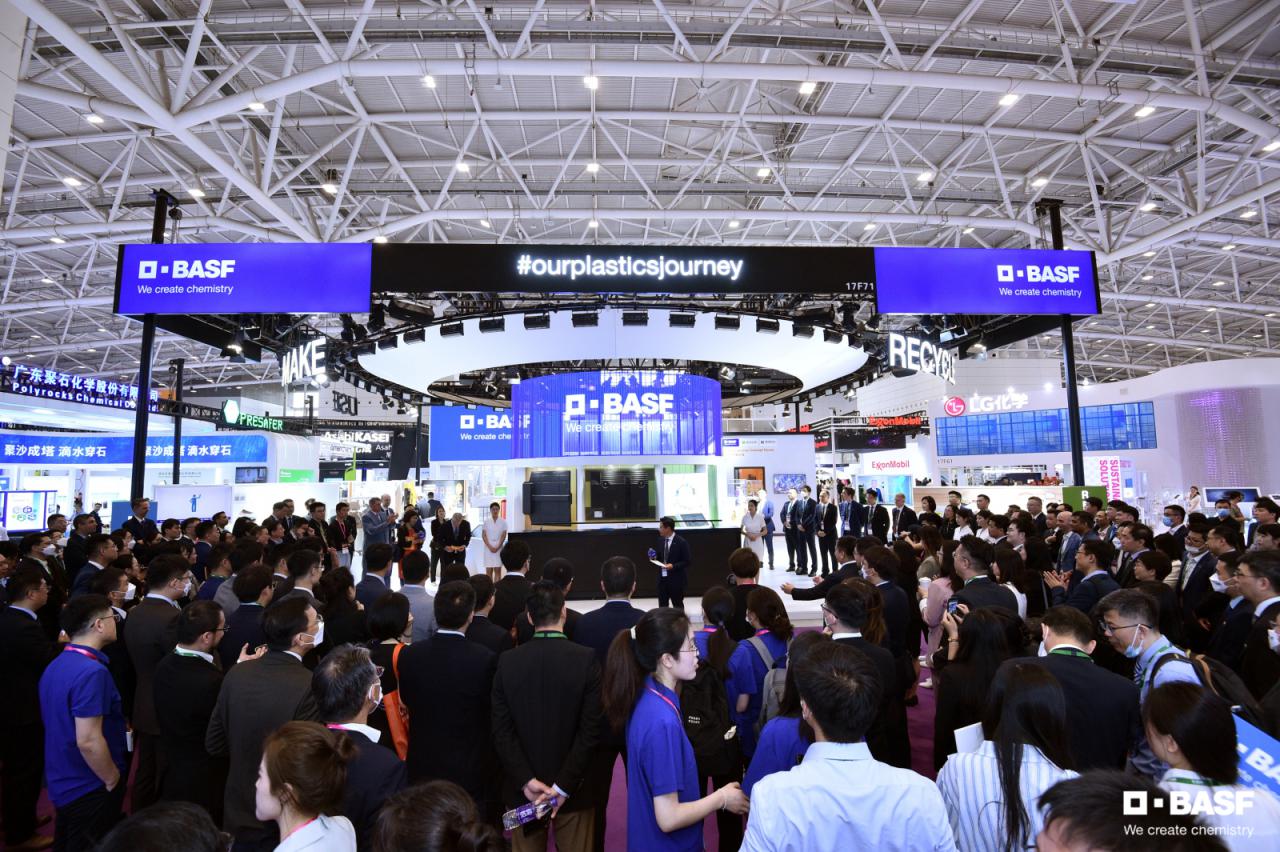

● BASF booth at CHINAPLAS 2023: Hall 17, Shenzhen World Exhibition and Convention Center, China, Booth 17F71

On April 17, 2023, Chinaplas 2023 officially opened. BASF focuses on the three stages of “manufacturing”, “use” and “recycling” of plastics under the theme of “Carbon Cable Road, Hand in Hand for Plastic”. BASF will demonstrate how it helps customers achieve sustainable development goals and promote their green progress.

Dr. Jianfeng Lou, Chairman and President of BASF Greater China, said: “As green transformation becomes a new growth driver for China’s economy, chemical innovation plays an important role in achieving sustainable development and a circular economy. As a world-leading chemical company , BASF is driving this transformation with innovation capabilities and commitment to sustainable development. We will work with customers and partners in the value chain to build a green and low-carbon future.”

Mass Balance – Certified Customer Value Chain and Product Carbon Footprint

At Chinaplas, BASF launched Biomass Balance (BMB) certified product brands, including Ultramid® polyamide (PA), Ultraform®

Polyoxymethylene (POM), Polyether Polyol Lupraphen, Elastopan® Polyurethane (PU), Elastollan® Thermoplastic Polyurethane (TPU). These certified grades are for

Complementary to Ultraform’s Biomass Balance grades launching October 2022. Ultraform biomass balance solution reduces by about 70% compared to conventional grades

Product Carbon Footprint (PCF).

Andy Bao, Senior Vice President of BASF, responsible for the Performance Materials Division in Asia Pacific

Postlethwaite said: “Biomass balance promotes the use of renewable raw materials, saves fossil resources, and reduces greenhouse gas emissions. Based on the mass balance method (ISO

22095) certified biomass balance grades can be customized according to customer needs. Together with our customers, we will develop tailor-made solutions to achieve their specific sustainability goals. ”

In parallel with the launch of the new biomass balance products, BASF will carry out more site certifications to verify its chain of custody from 2025, as well as chemical cycling (CCycled®

)product. Currently, all performance materials installations in China already run on renewable energy, which translates to a saving of 60% in CO2 emissions.

Enabling a sustainable future by promoting the growth of e-mobility and renewable energy through innovative and high-performance solutions

BASF announces that its TPU plant in Zhanjiang will open in 2023

It will be put into production in the second half of the year. Together with the plant for the production of modified engineering plastics, BASF will be able to meet the growing needs of customers in the Asia-Pacific region, especially in the automotive, electronics and electromobility industries –

In line with the trend of vehicle electrification and miniaturization of electronic equipment.

BASF has announced that starting from the second quarter of 2023, it will provide 50

A wide range of polyphthalamide (PPA) compounds to support market demand for lightweight, high-performance plastic components in the automotive industry, electrical and electronics (E&E) as well as mechanical engineering and smart consumer goods sectors.

Paul added: “Our investment and focus on collaboration, carbon management and enabling a circular economy are key to our next phase of growth. We will continue to support China and Asia Pacific with our comprehensive strengths, including design and simulation services innovative solutions.”

微信扫一扫打赏

微信扫一扫打赏