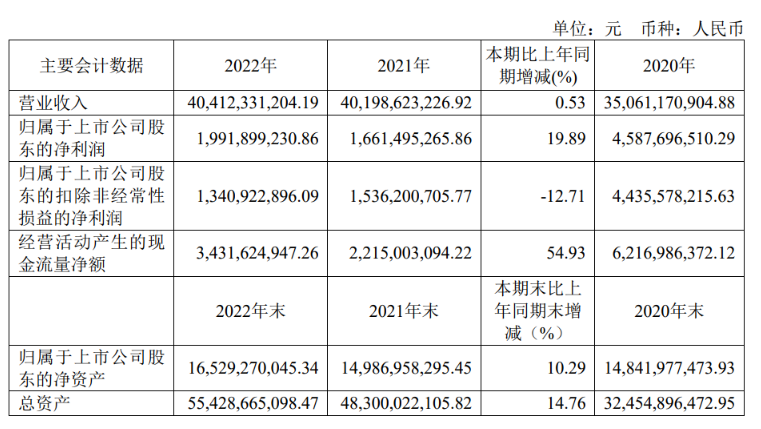

Kingfa Technology, a leader in modified plastics, disclosed its annual report on April 25, 2023. The company will achieve a total operating income of 40.412 billion yuan in 2022, an increase of 0.53% year-on-year; 19.89%. A cash dividend of RMB 2.30 (tax included) will be distributed for every 10 shares. In the first quarter of 2023, the company achieved operating income of 9.683 billion yuan, a year-on-year increase of 2.39%, and a net profit of 299 million yuan attributable to the parent company. The current market value of Kingfa Technology is 23.2 billion yuan.

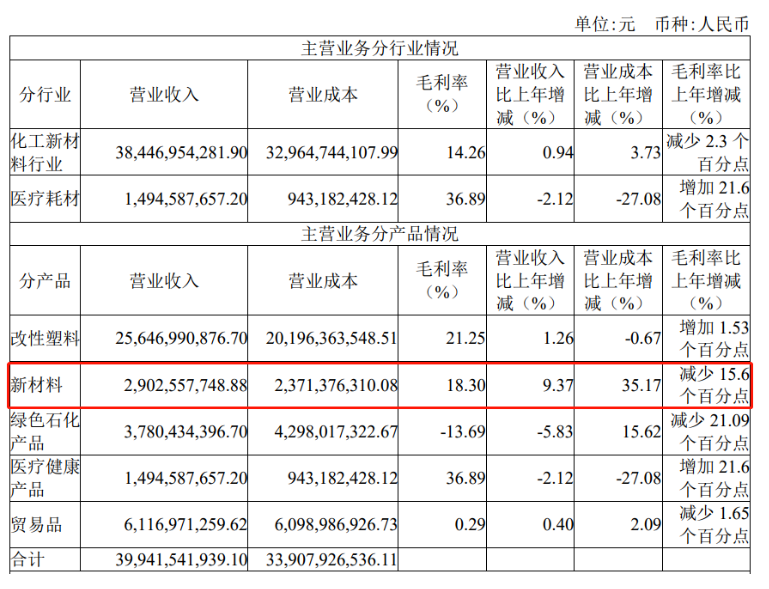

In the field of new materials, Kingfa Science and Technology will have an operating income of 2.903 billion yuan in 2022 and a gross profit margin of 18.30%. New materials include fully biodegradable plastics, special engineering plastics, carbon fibers and composite materials.

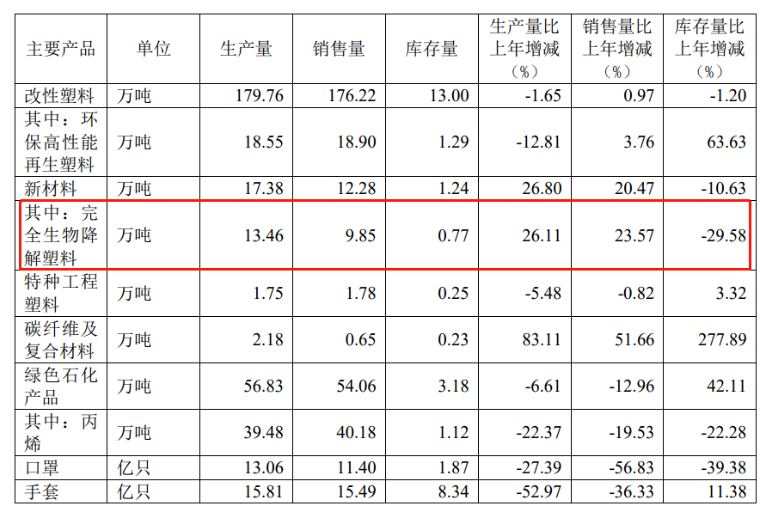

In 2022, the production capacity of fully biodegradable plastics of Kingfa Science and Technology will reach 210,000 tons per year, the capacity utilization rate will be 64%, the production volume will be 134,600 tons (an increase of 26.11%), the sales volume will be 98,500 tons (an increase of 23.57%), and the inventory will be 07,700 tons (a decrease of 29.58%). Kingfa sold 69,100 tons of degradable materials in the first three quarters

Kingfa Technology is one of the active advocates of fully biodegradable plastics in the world. It has fully mastered the core technologies of copolyester synthesis, reactive extrusion, alloying modification and end application, and is in the leading camp of fully biodegradable plastic manufacturers in the world. The company’s PBAT production capacity is the largest in Asia, and the Asian film bag market share is the first.

During the reporting period, the country continued to promote the policy of “banning and restricting plastics”. With the continuous improvement of the top-level design of plastic pollution control,

The domestic degradable plastic industry is gradually improving. However, affected by factors such as price fluctuations of upstream chemical monomer raw materials, economic downturn, and shrinking demand, the growth rate of demand for degradable plastics has slowed down significantly compared with the same period last year. In addition, new production capacity in the industry is gradually put into production, and disorderly competition has led to a decline in the overall profit of degradable plastic products.

As of the end of the reporting period, Kingfa Science and Technology has the ability to synthesize 180,000 tons of PBAT/PBS and 30,000 tons of PLA resin. The differentiated PLA products developed by the company form a complementary effect with PBAT products to meet the multi-faceted needs of the market; the company independently develops completely biodegradable plastic products such as blown film grade, extrusion grade, injection molding grade, and cast grade to meet end customer customization demand, and promote green transformation and upgrading under the “dual carbon” goal.

Regarding the business operation of biodegradable plastics, in response to rapidly changing market demands, Kingfa Science and Technology has established long-term strategic partnerships with major upstream suppliers to stabilize the prices of major raw materials and ensure the company’s raw material supply. In addition, the company has carried out technical transformation of the synthesis device, which has reduced manufacturing costs and improved production efficiency.

In addition, Kingfa Science and Technology has also established Liaoning Kingfa Biomaterials Co., Ltd. to deploy bio-based monomers and bio-based material technology research and industrialization construction, and steadily promote the construction of a bio-based BDO project with an annual output of 10,000 tons.

In terms of R&D and innovation, on the basis of the PBAT continuous production line, the company has developed the first domestic food-grade PBS product that meets the relevant standards for food contact through process optimization and equipment upgrades, which has enhanced the competitiveness of the company’s products. The company’s annual production of 30,000 tons of PLA continuous polymerization line has successfully tested and operated stably. The differentiated PLA products developed have complementary effects with PBAT products to meet the multi-faceted needs of the market. The company actively expands the types of biodegradable resins and extends product grades, forming a multi-variety supply capability that takes PBAT/PBS/PLA as the core and extends to blown film grades, extrusion grades, injection molding grades, and casting grades. The company has increased the application and development of modified special materials such as fully biodegradable plastic film, shopping bags, express bags, and packaging bags, and has achieved good technical application results in China.

Kingfa Technology stated that the company will continue to increase investment in research and development, develop more new biodegradable material products with better performance, and improve the market competitiveness of the company’s products.

微信扫一扫打赏

微信扫一扫打赏