According to the forecast of the China Automobile Association, the sales volume of new energy vehicles in China is expected to reach 9 million in 2023, and the amount of supporting charging piles and charging guns will also increase day by day.

Charging guns and on-board charging interfaces not only connect electric vehicles and charging piles, but are also related to the safety of users during charging. Therefore, there are high requirements for the insulation, reliability, and durability of materials used in components. At the same time, as high-power fast charging is favored by more and more car companies and users, it is becoming more and more important whether the charging module can be cooled efficiently and reliably. In response to these problems, Aimans has launched a series of solutions.

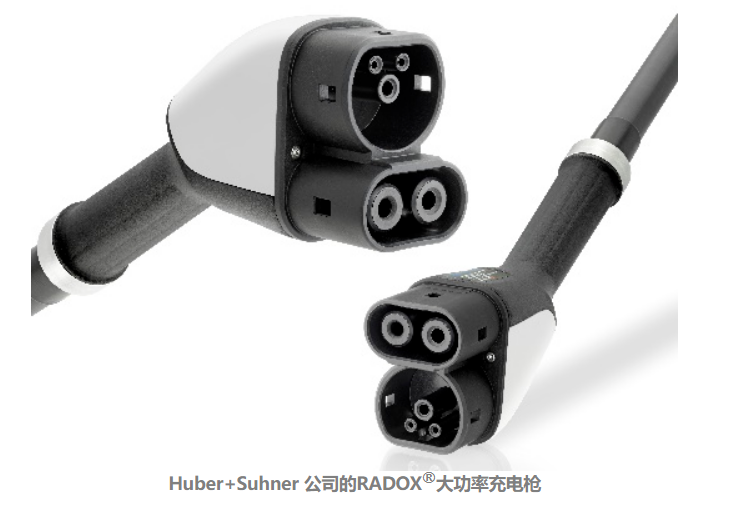

Emmans and the Swiss cable specialist Huber+Suhner jointly explored solutions for materials for high-power charging systems. Aimans’ long glass fiber technology equips its RADOX® high-power charging cables with connectors and cooling lines. At the same time, this app also won the twentieth SPE

(International Society of Plastics Engineers) 2nd Prize in the Electronics/Optics Category. Connector (PPA+LGF40

V0) can achieve 400A/1000V charging power, and has higher environmental adaptability and good low temperature impact resistance. It meets the UL-94 V0 flame retardant level, and the components meet UL

2251 standard.

Compared with the AC charging gun and the low-power charging gun, the overcharged charging gun needs corresponding cooling measures to ensure the safe operation of the device due to the circuit heating caused by the large current (up to 400A) during the charging process. RADOX® adopts active liquid cooling, and its cooling pipeline is made of Aymans long-chain nylon material (PA12)

Made, this material is halogen-free, has good flexibility and hydrolysis resistance.

The charging socket panel on the vehicle body is used to fix the charging socket. In addition to meeting the installation requirements of the socket and conforming to the structural design, it also needs to withstand considerable plugging force during the charging process to ensure the safe operation of the charging process. Emmans’ PPA

The body charging socket panel made of GF (V0) flame-retardant material has high rigidity and high strength, and can meet the plug-in force of 750N / 1800N (with lock)

At the same time @23℃, the weight is reduced by 35%, the overall cost is saved by 40%, and it meets the UL-94 V0 flame retardant rating.

微信扫一扫打赏

微信扫一扫打赏