Local companies break through key technologies, and the process of domestic substitution in the domestic CMP polishing slurry market accelerates

CMP polishing slurry, chemical mechanical polishing slurry, refers to a water-soluble polishing agent composed of solid particle abrasives, surfactants, stabilizers, oxidants and other ingredients. According to different processes, CMP polishing fluid can be divided into dielectric layer chemical mechanical polishing fluid, barrier layer chemical mechanical polishing fluid, copper chemical mechanical polishing fluid, silicon chemical mechanical polishing fluid, tungsten chemical mechanical polishing fluid, TSV chemical mechanical polishing fluid, shallow groove Isolate chemical mechanical polishing fluid, etc.

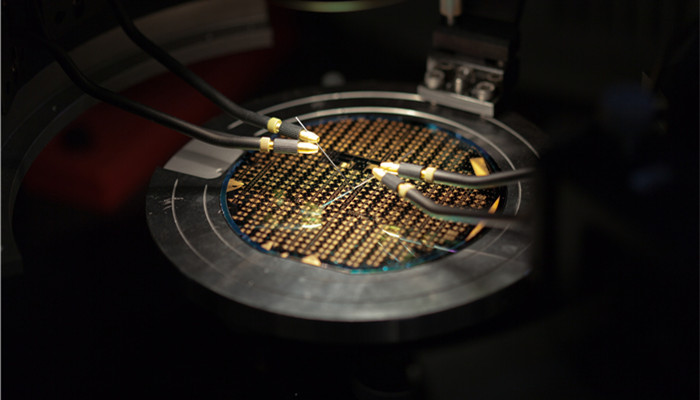

CMP polishing slurry is one of the main materials required in the semiconductor wafer manufacturing process and plays a key role in the wafer polishing process. The type, particle dispersion, particle size, physical and chemical properties and stability of the polishing slurry are all related to Polishing effect is closely related. In recent years, against the background of the continuous development of technologies such as artificial intelligence, 5G, and data centers, the application fields of wafers have continued to expand, and the market size has continued to expand, which in turn has driven the increasing market demand for CMP polishing fluids.

From the perspective of the global market, the global wafer market size will be approximately US$109.2 billion in 2021, a year-on-year increase of 25%. Driven by the development of the wafer market, the global CMP polishing slurry market size will be US$1.91 billion in 2021, a year-on-year increase of 14.3%. The global CMP polishing slurry market is dominated by U.S. and Japanese companies such as Cabot Microelectronics, Hitachi, FUJIMI, and Huizhan Materials. In 2021, U.S. and Japanese companies together account for approximately 66% of the market share. However, in recent years, domestic company Anji Technology has achieved technological breakthroughs in the field of semiconductor polishing fluids. In 2021, it occupied about 6% of the global market share.

From the perspective of the Chinese market, the wafer market size in 2021 will be approximately 295.74 billion yuan, a year-on-year increase of 12.7%. In this context, according to the《 “Special Research Report on CMP Polishing Fluid Benchmark Companies and Competitors 2022-2026” shows that the domestic CMP polishing fluid market size in 2021 will be 1.87 billion yuan, a year-on-year increase of 26.5%. CMP polishing slurry has complex ingredients and high R&D barriers. For different wafer manufacturing processes, the composition and concentration of the polishing slurry formula need to be optimized and adjusted accordingly. Therefore, the entry threshold for the industry is high. At present, domestic companies mainly include Anji Technology , Shenzhen Lihe, Dinglong Co., Ltd., Shanghai Xinyang, Shanghai Xinanna, etc.

Among them, the domestic CMP polishing slurry market is dominated by Cabot Microelectronics and Anji Technology. In 2021, Anji Technology will occupy approximately 33% of the domestic market share. There is huge room for domestic substitution in the domestic CMP polishing slurry market. In the future, as local companies continue to break through key technologies, the domestic substitution process will continue to accelerate.

Industry analysts personnel said that in recent years, as the global semiconductor industry chain has accelerated its transfer to mainland China, the wafer market has continued to grow in size. The expansion stimulates rapid growth in market demand for CMP polishing slurries, and the industry has good development prospects. Although the domestic CMP polishing slurry market is still dominated by foreign companies, local company Anji Technology has achieved breakthroughs in key technical fields, and its share of the domestic market continues to increase. In the future, the process of domestic substitution will continue to accelerate, and the industry has huge development potential. .

微信扫一扫打赏

微信扫一扫打赏