Nylon 6,6 has excellent performance and plasticity, and its modification, research, development and application have great market prospects in new energy vehicles and other fields. For example, replacing metal parts in the interior of a car with comparable strength nylon 6,6 engineering plastics can lead to significant weight savings and significantly improved safety.

In order to better develop material application fields and provide faster R&D support, INVISTA established a new Asia-Pacific Research and Innovation Center (AIC) in Shanghai Chemical Industry Park last year. As the first R&D center in the Asia-Pacific, AIC empowers INVISTA to introduce global innovation strength to China, radiate regional demand, support, strengthen and upgrade the layout of the nylon 6,6 value chain.

So, how does the INVISTA Asia-Pacific R&D Center make full use of its own strengths and develop various applications?

Application-led, joint efforts to innovate!

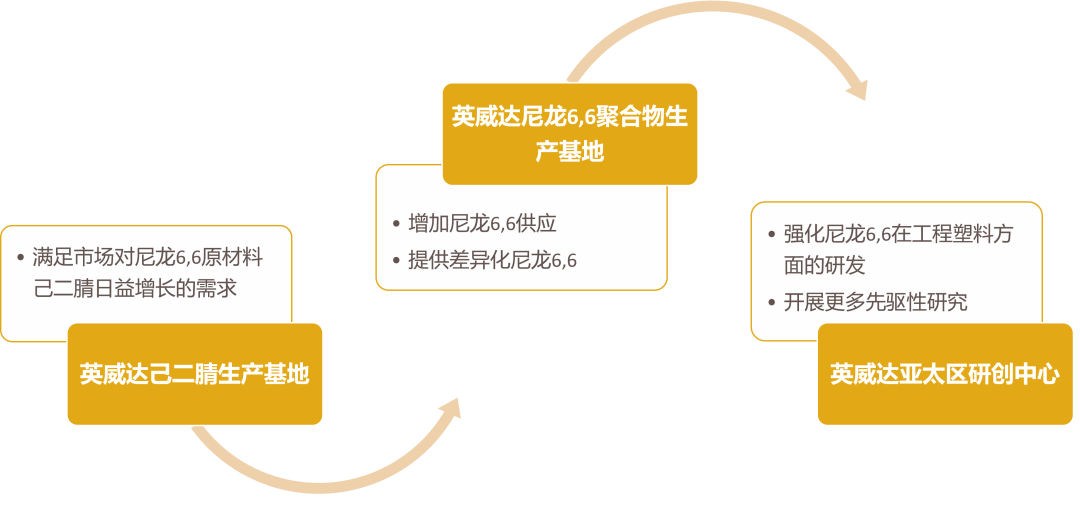

With the completion of INVISTA’s adiponitrile production base, and nylon 6,6

With the start of the polymer production expansion project, the regional market dominated by Asia will usher in more demand for high-end nylon 6,6 applications. Therefore, the INVISTA Asia-Pacific R&D Center is positioned in the application and development of downstream nylon 6,6 products——

On the basis of close cooperation with downstream modification customers, the Asia-Pacific Research and Innovation Center will assist customers in developing the required formulations and processes, give full play to INVISTA’s innovative capabilities in basic slicing, and provide differentiated resins, process optimization, analysis testing and CAD/CAE A series of technical solutions such as simulation provide support for the application and development of nylon 6,6.

Relying on the synergistic effect brought by the adiponitrile and polymer production bases, INVISTA will also provide customers and partners with differentiated nylon 6,6 basic slices, and accelerate the mass production of the research and innovation center’s development results and push them to the market.

Global cooperation, each draws on its strengths!

In addition to cooperating with local industry chain partners, the Asia-Pacific R&D Center will also link up with INVISTA’s R&D centers in other regions of the world to improve the performance of nylon 6,6 and broaden its application scope through research and development and technology sharing covering different fields.

Currently, INVISTA has four R&D centers around the world, covering the entire production process of nylon 6,6.

United States: Process optimization and development of adiponitrile, a raw material for nylon 6,6

UK: R&D of nylon 6,6 polymer

Canada: Development of nylon 6,6 in fiber applications (eg, airbag fibers)

Asia-Pacific: Research and Development of Nylon 6,6 Terminal Application in Engineering Plastics

In response to different customer needs, each research and innovation center collaborates to innovate and give full play to their strengths. For example, when customers put forward new demands, the UK R&D Center will develop a new nylon 6,6 product formula and production process, and the Asia-Pacific R&D Center will use the new nylon 6,6 slices for formula design and analysis and measurement to complete Application development to meet customer needs.

At the same time, each research and innovation center will also conduct in-depth discussions and cooperation in project development, testing methods, laboratory management, safety production and intellectual property protection, and work together to enhance INVISTA’s basic research and development capabilities.

Innovation is the core of INVISTA’s value creation for customers and industry development. In order to quickly respond to changing market demands, relying on the Asia-Pacific R&D Center, INVISTA will carry out more pioneering basic research work to broaden the possibility of nylon 6,6 application in the field of engineering plastics.

In this way, INVISTA will also continue to track the application trend of the terminal market, and work with partners to strive to support the upgrading of downstream application fields with more innovative practices!

微信扫一扫打赏

微信扫一扫打赏