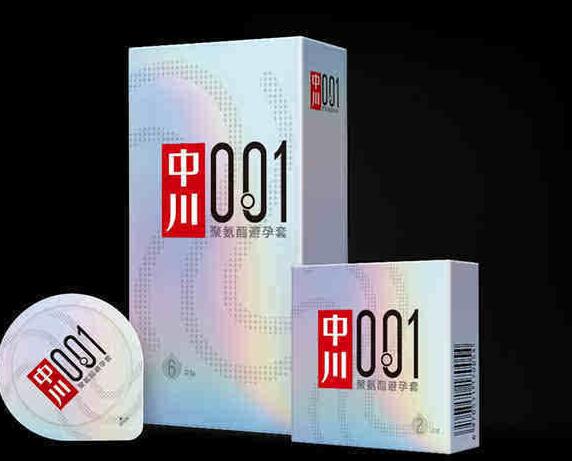

From manufacturing to “smart” manufacturing, China is in progress in 2017 A gorgeous turn. From the official launch of China-made ballpoint pen refills in January, to the successful launch of China’s first domestic aircraft carrier on April 26, the successful first flight of the domestically-made large aircraft C919 with completely independent intellectual property rights on May 5, and the successful maiden flight of China’s first thin-film aircraft carrier on May 20 To 0.01 water-based polyurethane condom Zhongchuan 001 brand was officially released in Shanghai, and JD.com launched its global launch simultaneously, breaking the situation where foreign brands monopolize the polyurethane condom market in one fell swoop, and becoming an important “Made in China” brand comparable to domestic aircraft carriers, domestic large aircraft, and ballpoint pen refills. pound event.

Today, when China’s manufacturing scale has become the largest in the world, we are no longer satisfied with low value-added, labor-intensive manufacturing industries, and moving towards technology-based and brand-oriented industries has become an important proposition today. Technological breakthroughs such as domestic aircraft carriers, domestic large aircraft, ballpoint pen refills, and ultra-thin condoms have watershed significance: the technology of domestic large aircraft C919 and domestic aircraft carriers is reflected in high-tech breakthroughs in large machinery and heavy industry; while water-based polyurethane condoms, The ballpoint refill looks small, but it has high requirements for special materials and precision processing, and it belongs to the core of high-precision technology.

Domestic 001 polyurethane condom breaks the monopoly pattern of foreign brands

China is one of the largest consumers of condoms in the world. Statistics show that the annual consumption of condoms in China is 9.6 billion, the age group covers nearly 700 million people, and the regular consumer population is close to 90 million. The annual production of condoms in China exceeds 10 billion. Experts predict that the sales of condoms in China will maintain a growth rate of more than 15%, and the market potential is more than 10 billion yuan.

However, China, which ranks among the top in the world in condom consumption and production, lacks the core technology for condom development and can only mass-produce low-tech traditional latex products, which puts domestic condom production and R&D enterprises in an awkward situation. This embarrassing situation was reversed with the launch of Zhongchuan 001, China’s first water-based polyurethane condom. It is understood that Zhongchuan 001 is led by Professor Wang Wusheng, one of the pioneers of China’s water-based polyurethane industry and the father of China’s polyurethane condoms. After 30 years of theoretical accumulation and more than 20 years of industrial application practice, it finally conquered the core of 0.01 water-based polyurethane condoms. Technology, successfully developed and approved for listing. This breakthrough is expected to change the pattern of China’s condom market and allow Chinese companies to seize a “place”.

The top of the pyramid of beach-grabbing technology, water-based polyurethane condoms and ballpoint pen refills are “small but precise”

Similar to the field of water-based polyurethane condoms is the ballpoint pen refill industry. China is a well-deserved pen-making power. A seemingly insignificant pen requires not only easy-cutting stainless steel wire, but also requires the machining accuracy of the ball and ball seat to reach one thousandth of a millimeter. However, due to the absence of mold steel and precision machining technology, we have not been able to get rid of the shackles of foreign companies for a long time.

Compared with ballpoint pen refills, China is proud of water-based polyurethane materials. Before Ketian Health, only a few countries in the world have mastered the technology of water-based polyurethane materials. However, water-based polyurethane condoms are the highest-level challenge in the field of water-based polyurethane material research.

Professor Wang Wusheng told us that water-based polyurethane materials are mostly used in coatings and adhesives, and are attached to other materials, while polyurethane condoms are the first time water-based polyurethane materials are used as body materials, due to their low modulus and high strength. (Soft and strong) is the natural weakness of water-based polyurethane materials. The technical research and development of water-based polyurethane condoms involves core technologies such as cutting-edge material synthesis and resin molding. 0.01 itself is challenging the limit of film material thickness. In 2013, the Bill and Melinda Gates Foundation’s “Developing the Next Generation of Condoms” program emphasized that no matter students, scientists, or entrepreneurs, as long as they can bring innovation to condoms, they can get 100,000 US dollars to start funding, with an additional $1 million in incentives. It can be seen that the research and development of condoms is difficult.

However, under the assiduous research of the “Dream Team” led by Professor Wang Wusheng, Ketian Health has continuously broken through technical barriers, and has applied for 25 invention patents, including 20 patents for water-based polyurethane condom resin and water-based polyurethane condom patents. 5 technologies. The advent of Zhongchuan 001 has broken Japan’s technical monopoly in the field of water-based polyurethane condoms. The quality of Zhongchuan 001 produced is comparable to that of the world, and it is in the forefront of the world.

At the same time, Ketian Health also has the world’s first 100,000-ton water-based polyurethane production line, China’s first water-based polyurethane condom production line, and is the first enterprise in China to obtain the production license and sales license of polyurethane condoms , The only company in the world that masters the dual technology of water-based polyurethane resin and water-based polyurethane condom production.

In addition to producing aircraft carriers, airplanes, ballpoint pen refills, and condoms, the next step is to incubate brands

Two years ago, China promulgated the “Made in China 2025” long-term strategic plan to promote the optimization and upgrading of Chinese enterprises, from “production-oriented” to “technology + brand + production + service” enterprises.Changes in the operating system. This is an important measure to promote the transformation from Made in China to Created in China, from Chinese Speed to Chinese Quality, and from Chinese Products to Chinese Brands. It will also inevitably empower domestic brands at the policy, industry, and market levels.

In fact, whether it is a large aircraft carrier, a large aircraft, a condom, or a ballpoint pen, they are all a microcosm of the transformation and upgrading of China’s manufacturing industry. growth history. Core technology can lead an industry to reverse the global competition pattern, which has typical benchmarking significance. At the same time, the transformation from core technology to brand added value is a more critical step. At the Zhongchuan 001 brand launch event, it signed a contract with the NBA Houston Rockets and became an official designated product, bringing Chinese products onto the international stage. It can be predicted that with the release of Zhongchuan 001, with the core technology as the driving force and brand communication as the starting point, it will not only break the monopoly situation, but also is expected to cultivate innovative and leading competitive brands on a global scale.

微信扫一扫打赏

微信扫一扫打赏