IPDI: Isophorone diisocyanate, a cycloaliphatic diisocyanate, is a synthetic The preferred raw material for light-stable and weather-resistant polyamic acid is a high-end product among isocyanate raw materials. Mainly used in water-based polyurethane dispersions, anti-corrosion coatings, UV resins, adhesives, PU resins, inks and other fields. At the same time, IPDI can also be used in the rocket propellant industry.

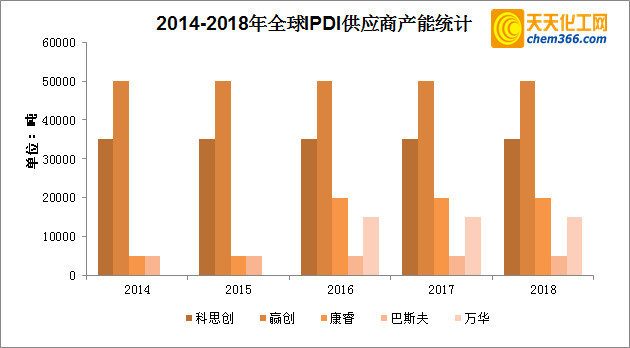

From 2014 to 2015, the global IPDI device production capacity remained unchanged, mainly concentrated in Evonik, Covestro, BASF and Kangrui business hands. Due to the high technical threshold of IPDI and the long synthesis route, there was no IPDI manufacturers, domestic IPDI are imported.

At the beginning of March 2016, the IPDI (isophorone diisocyanate) production line independently developed by Wanhua Chemical was officially put into production and the output was qualified product. With the successful commissioning of this brand new IPDI production facility, Wanhua Chemical has become one of the few in the world that owns the “IP-IPN-IPDA-IPDI” is one of the enterprises with the core technology of the whole industry chain, and it has also ended the IPDI is completely dependent on imports, and the domestic IPDI market structure has quietly changed.

According to the statistics of Tiantian Chemical Network, the compound growth rate of global IPDI production capacity reached about 7.1% from 2014 to 2018. From 2014 to 2018, the expansion of global IPDI mainly came from Wanhua and Kangrui. An increase of 30,000 tons. Up to now, the global production capacity of IPDI is mainly concentrated in North America, Europe and Asia. For more details, please see the 2018 China IPDI market report provided by Suntowers Consulting!

微信扫一扫打赏

微信扫一扫打赏