Cold chain logistics It refers to a systematic project that refrigerated and frozen food is always kept in the low temperature environment specified by the product in all links of production, storage, transportation, sales, and consumption, so as to ensure food quality and reduce food loss. The target products of cold chain logistics include general products and special products. General products include agricultural products, poultry meat, aquatic products, flowers, processed foods, frozen or quick-frozen foods, ice cream and egg milk products, fast food ingredients, wine and beverages, etc. Special products include medicines (vaccine, blood), chemicals, etc.

Cold chain logistics Advantages: 1) Reduce food loss rate. Perishable products such as vegetables and meat are mostly loaded in the open air instead of in cold storage and heat preservation places. Only fruits, vegetables and other agricultural products have a loss rate of about 100% in logistics links such as picking, transportation, and storage.20%. The cold chain logistics provides a guarantee for the safe delivery of food. Fresh food requires complete cold chain logistics to control the temperature of the goods throughout the process to ensure food safety, and cold chain logistics can achieve a closed environment when loading and unloading goods, thereby greatly reducing the loss rate. 2) to reduce product markup. Under the traditional model, fresh food from farmers to consumers must at least go through distribution markets at the origin, wholesalers at the origin, first-tier wholesalers at the destination, second-tier wholesalers at the destination, supermarkets, farmers’ markets, restaurants and other channels. There is a price increase20%-30%in each of the above links In some cases, the total markup rate can be as high as110%. Cold chain logistics can establish a direct supply system from suppliers to channels, reduce intermediate links in the fresh food circulation process, and reduce product markup rates.

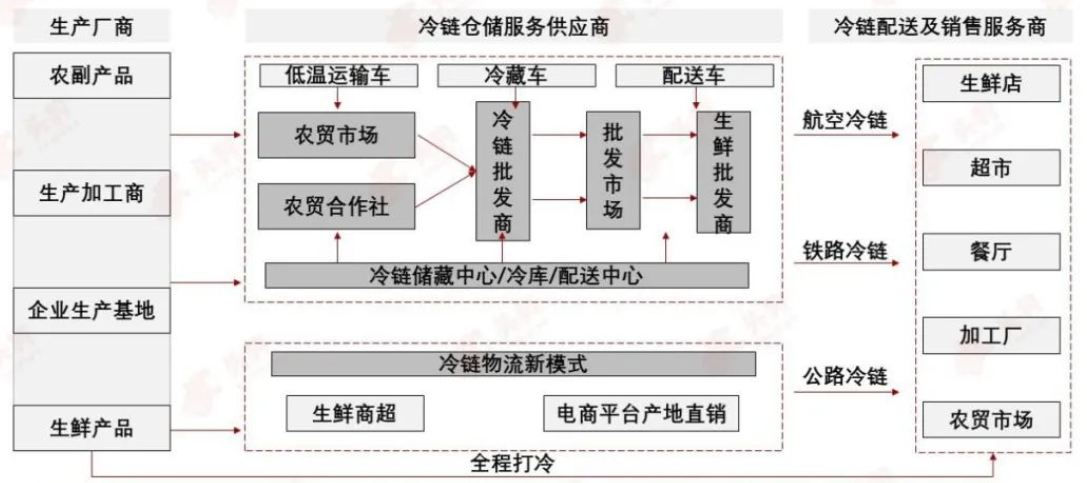

Figure 1 Cold chain transportation process

my country’s cold chain The development of the logistics industry is divided into three stages: the first stage is the embryonic stage (1998year-2007year), many Logistics companies do not yet have the concept of “cold chain logistics”. Cold chain facilities and equipment are generally lacking and backward, and cold chain resources are mainly concentrated in state-owned enterprises. The second stage is the initial stage (2008-2017year) , with the rapid development of China’s frozen food industry, the cold chain logistics industry has also begun to develop. Many enterprises have started to set foot in the cold chain market. Central enterprises such as Sinotrans and China Merchants have deployed cold chains. Upstream food companies such as Shuanghui and Guangming have established independent logistics companies. Cold chain companies such as Amcold, Purface, and Swire have also entered the Chinese market one after another. Currently in a stage of rapid development (2018 to the present), The national cold chain demand is exploding, the infrastructure system is becoming more and more perfect, and the industry has entered the cold chain3.0The era is mainly reflected in the upgrading of five aspects: industrial environment, cold chain awareness, technical equipment, personnel management and business philosophy.

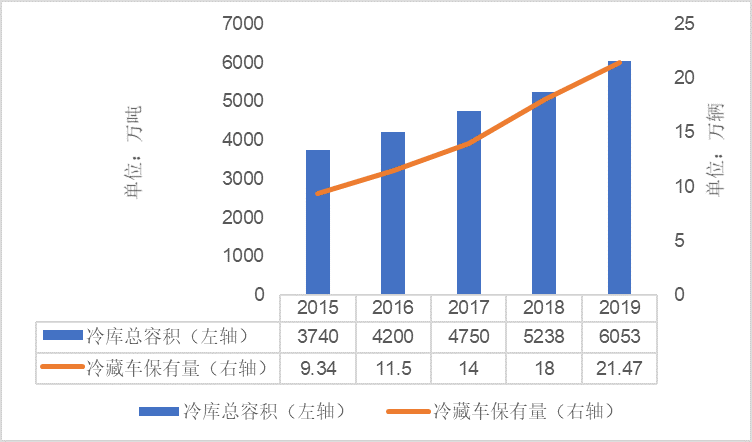

The high growth of fresh food market demand has driven Development of cold chain logistics industry:In recent years, the proportion of fresh food consumption has been increasing, the demand for fresh food market has surged, and the fresh food e-commerce trading market Significantly increased in size. 2020<�Increased from 374010,000 tons to605310,000 tons, with a compound annual growth rate of 12.8%;2015-2019The number of refrigerated trucks in China in 2015 from9.3410,000 vehicles increased to21.4721.4710,000 units, the average annual compound growth rate is23.1%. The rapid growth of cold storage and refrigerated trucks shows that the infrastructure construction of my country’s cold chain logistics industry is gradually improving.

Figure4 2015-2019The total volume of cold storage and the number of refrigerated trucks in China

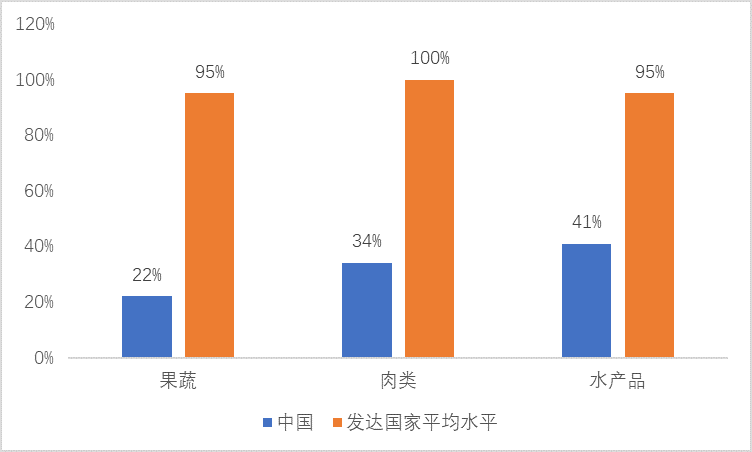

There is still a big gap between my country’s cold chain logistics development level and developed countries. At present, the cold chain circulation rate in my country is still very low, and the cold chain circulation rates of fruits and vegetables, meat and aquatic products are respectively22%,34%and41% , far below the average level of developed countries. The wear rate of fresh food in my country is also higher than the average level of developed countries. The wear rate of fruits and vegetables, meat and aquatic products are respectively 15%、8%and10%. Compared with the average level of developed countries, the circulation rate of cold fresh products in my country is low and the wear rate is high, which shows that there are still many weak links in my country’s cold chain infrastructure system.

Figure5Comparison of cold chain circulation rates between China and developed countries

Figure6Comparison of fresh food wear rates between China and developed countries

Smart cold chain logistics is the main development trend in the future:Smart cold chain logistics is the application of Internet of Things technology to the cold chain logistics industry to help upgrade the cold chain The operation mode of logistics, including in-warehouse operation, transportation management and management efficiency enhancement. Smart warehousing technology can help enterprises standardize all aspects of cold chain operations, effectively monitor the entire process of cold chain logistics, improve the management level and operational efficiency of cold chain business, reduce the overall cost of the supply chain, and improve resource utilization efficiency, thereby achieving cost reduction and efficiency increase. Intelligent transportation technology usesRFIDandGPSpositioning and tracking technology, etc., to realize the tracking of items and vehicles involved in the cold chain logistics link Carry out real-time monitoring and supervision. Smart cold chain logistics can provide enterprises with a more efficient supply chain management system, conduct dynamic monitoring of the entire process of products, and achieve refined management. At present, well-known enterprises such as SF Express and JD.com have efficient and advanced cold chain supply chain integrated management systems. Smart cold chain logistics is the main development trend in the future. The cold chain logistics industry will continue to develop in the direction of big data and artificial intelligence. A large-scale smart cold chain system can be expected in the future.

Reduce costs and improve the efficiency of resource use, thereby reducing costs and increasing efficiency. Intelligent transportation technology usesRFIDandGPSpositioning and tracking technology, etc., to realize the tracking of items and vehicles involved in the cold chain logistics link Carry out real-time monitoring and supervision. Smart cold chain logistics can provide enterprises with a more efficient supply chain management system, conduct dynamic monitoring of the entire process of products, and achieve refined management. At present, well-known enterprises such as SF Express and JD.com have efficient and advanced cold chain supply chain integrated management systems. Smart cold chain logistics is the main development trend in the future. The cold chain logistics industry will continue to develop in the direction of big data and artificial intelligence. A large-scale smart cold chain system can be expected in the future.

微信扫一扫打赏

微信扫一扫打赏