Chem366– Polyamide (PA ) commonly known asNylon (Nylon), Is the United States DuPont The company was the first to develop resins for fibers. Currently the most used is PA6 and PA66, about PA consumed 90% above. Nylon66is a translucent or opaque milky white crystalline polymer with excellent mechanical properties, self-lubricating properties, heat resistance and electrical insulation properties. In terms of physical properties, nylon66It can also maintain strong strength and rigidity at higher temperatures; nylon66Higher mechanical strength, good stress crack resistance, is the best wear-resistant nylon; nylon66Excellent self-lubrication, second only to polytetrafluoroethylene and polyoxymethylene; nylon66Heat is also good, it is a self-extinguishing material, but it has high water absorption, so its dimensional stability is poor. In terms of chemical properties, nylon66It has good chemical stability and is resistant to many solvents, especially oil resistance, but it is resistant to acid And some other chlorinating agents have weak resistance, and are easily soluble in polar solvents such as phenol and formic acid. Adding carbon black can improve weather resistance. As a leader in engineering plastics, nylon66High strength, high temperature resistance, chemical resistance, high hardness and wear resistance And other advantages, widely used in rubber, tires, plastics, electronics, chemicals, chemical fiber and other industries.

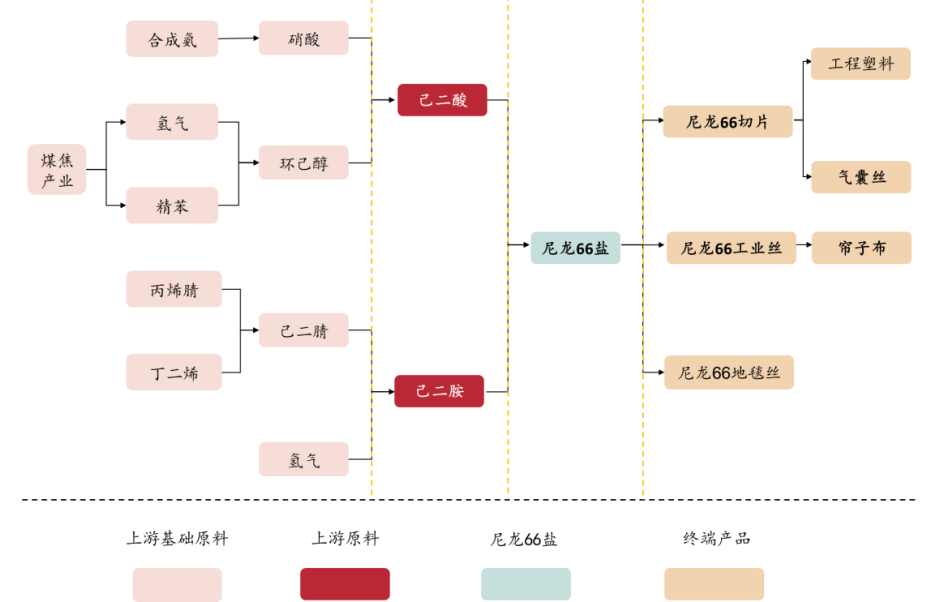

Nylon 66 Core material nylon 66 The salt can be obtained from the neutralization reaction of two intermediates, adipic acid and hexamethylenediamine. Two nitrile hydrogenation system. Although my country has been able to produce nylon 66 Salt, adipic acid and hexamethylenediamine, but the upstream basic raw material adiponitrile market has long been controlled by Europe.�Manufacturer-led.

Figure1 Nylon66Upstream and downstream industry chain

Table1 Nylon66Comparison of performance with other nylon materials

|

|

Nylon6 |

Nylon66 |

Nylon11 |

Nylon12 |

|

Density (g/mL) |

1.084 |

1.13~1.16 |

1.03~1.05 |

1.01~1.03 |

|

Melting point(℃) |

220 |

260 |

183~188 |

172~178 |

|

Glass transition temperature (℃) |

40-60 |

47 |

115 |

125~155 |

|

Water absorption |

%)

Figure4 2013-2020Year Chinese Nylon66Production situation ( Unit: 10,000 tons)

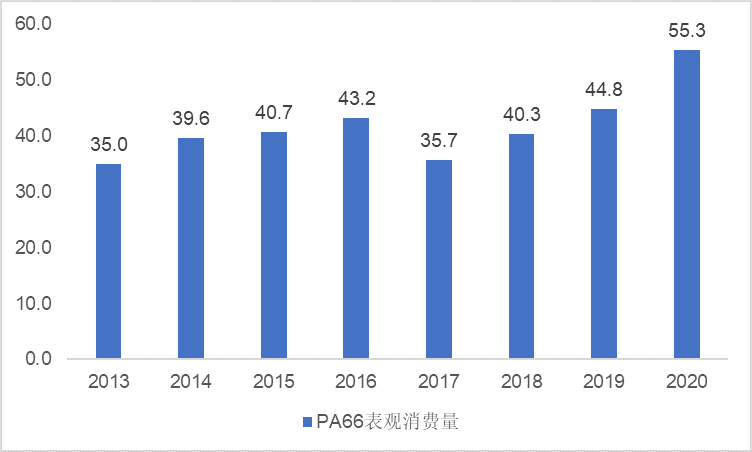

Figure5 2013-2020Year Chinese Nylon66Apparent consumption Quantity (unit: 10,000 tons)

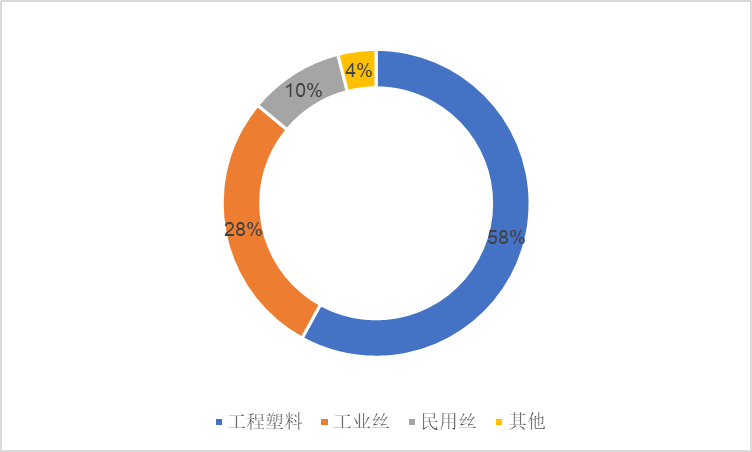

Nylon in China66 is the largest application field of engineering plastics, the consumption The proportion is58%. Industrial yarn, civilian yarn and nylon for other applications66 The proportion of consumption is 28%, 10%and4%. Among them, in engineering plastics47% Nylon 66Used in the automotive industry,28% Nylon 66Used in electronics,25%Nylon 66 Used for rail transit.

Figure6 2020年中国PA66downstream consumption structure

Figure7 Chinese Nylon 66 Specific application in the field of engineering plastics

For a long time, nylon in China 66The self-sufficiency rate has been insufficient, the main reason is the core raw materials Adiponitrile has not been broken through, thus limiting nylon 66Industrial development. In recent years, breakthroughs in the key technologies of adiponitrile in my country have emerged, and many companies have successively put into production adiponitrile projects in China. Nylon 66Self-sufficient raw materials Nylon 66 The production technology has made great progress. In the future, with the gradual localization of the key raw material adiponitrile, the domestic “>PA66The market size is expected to be greatly improved. According to INVISTA’s prediction, under the general trend of replacing steel with plastic,PA66Based on its higher melting point, lower water absorption, better hydrolysis resistance, oil resistance and friction resistance, it is expected to gradually replace metal,PA6 and other modified plastics. PA66Integrated into the interior of the electric vehicle, it can reduce the weight of the vehicle30%, and significantly improve security, with great potential for future applications. l”,sans-serif”>6 2020 ChinaPA66Downstream consumption structure

Figure7 Chinese Nylon 66 Specific application in the field of engineering plastics

For a long time, nylon in China 66The self-sufficiency rate has been insufficient, the main reason is the core raw materials Adiponitrile has not been broken through, thus limiting nylon 66Industrial development. In recent years, breakthroughs in the key technologies of adiponitrile in my country have emerged, and many companies have successively put into production adiponitrile projects in China. Nylon 66Self-sufficient raw materials Nylon 66 The production technology has made great progress. In the future, with the gradual localization of the key raw material adiponitrile, the domestic “>PA66The market size is expected to be greatly improved. According to INVISTA’s prediction, under the general trend of replacing steel with plastic,PA66Based on its higher melting point, lower water absorption, better hydrolysis resistance, oil resistance and friction resistance, it is expected to gradually replace metal,PA6 and other modified plastics. PA66Integrated into the interior of the electric vehicle, it can reduce the weight of the vehicle30%, and significantly improve security, with great potential for future applications.

This article is from the Internet, does not represent the position of Epoxy curing agent, reproduced please specify the source.https://www.dmp-30.vip/archives/8901

|

微信扫一扫打赏

微信扫一扫打赏