Shandong Province is a senior chemical industry province in the country. In 1992, after the output value of Shandong chemical industry surpassed that of Jiangsu for the first time, the economic aggregate of Shandong chemical industry ranked first in the country for 28 consecutive years. The chemical products listed in the national key statistics are all distributed, forming an industrial system of “seven major sectors” of refining, chemical fertilizers, inorganic chemicals, organic chemicals, rubber processing, fine chemicals, and synthetic materials. The output of key chemical products ranks among the top in the country.

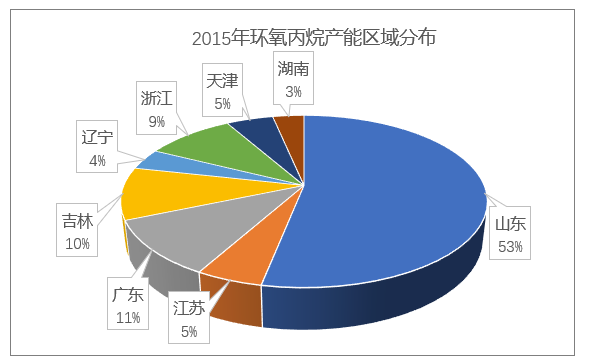

Shandong has a large oil field with an annual output of more than 20 million tons of crude oil—Shengli Oilfield, a group of backbone coal mines including Shandong Energy, with an annual output of more than 100 million tons of coal, and Qingdao, a large northern port And Dongying, the comprehensive conditions of raw material supply are hard to come by in China. Relying on good resources, logistics and location economic conditions, Shandong has formed the country’s largest oil refining capacity, and its primary crude oil processing capacity accounted for 30% of the country’s total capacity at one time. , chemical fertilizers and new coal chemical industry have also been leading the country. Relying on a strong basic raw material industry, Shandong propylene oxide occupies a place in China. In 2015, Shandong’s propylene oxide production capacity accounted for 53% of the country’s total.

Since the launch of the special campaign for the transformation and upgrading of chemical industry safety production in 2017, Shandong Province has completed the rating and evaluation of more than 7,700 chemical production, hazardous chemical storage and transportation enterprises, and 2,369 companies have failed to meet the standards. Enterprises have withdrawn in an orderly manner. By the end of 2020, the number of chemical production enterprises above designated size in Shandong Province has dropped to 2,847, accounting for 12% of the country. The “high energy consumption, high pollution, and high risk” of Shandong’s chemical industry has been transformed into “high-quality development, high-end chemicals, and high-efficiency parks.”

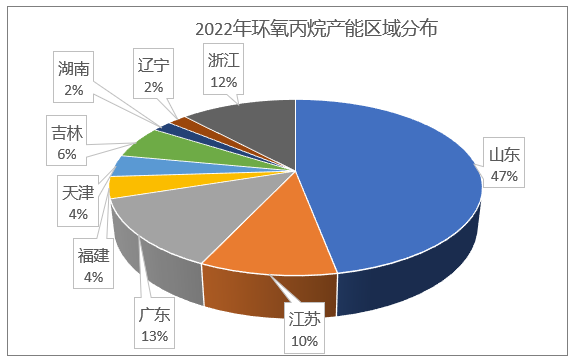

From the evaluation of aldehyde value, content, moisture and other indicators, the chlorohydrin method of propylene oxide is mature, with good quality and relatively low investment. It has always been the mainstream process of cyclopropane in China. The “Industrial Structure Adjustment Guidance Catalog (2011 Edition)” promulgated by the Chinese government in 2011 clearly stipulates that new chlorohydrin-based propylene oxide plants will be restricted. With the intensification of environmental protection inspections and the forced production reduction or even shutdown of most chlorohydrin-based propylene oxide plants, including Fujian Meizhou Bay, the operating rate is low. The propylene oxide process in Shandong Province is still dominated by the chlorohydrin method, and its market share is decreasing year by year. According to the statistics of Tiantian Chemical Network, the proportion of propylene oxide production capacity in Shandong Province will be reduced from 53% in 2015 to 47% in 2022.

The number of chemical companies in Jiangsu, Shandong, Zhejiang and other eastern coastal provinces has dropped sharply, and they are gradually expanding to the central, western and northeastern regions. Data shows that since 2019, there have been as many as 632 new transfer projects in the Midwest and Northeast! Originally, 16 prefecture-level cities in Shandong had hazardous chemical production and operation enterprises, and more than 60,000 hazardous chemical transport vehicles drove on the roads in the province every day. After five years of rectification, Shandong Chemical Industry Park was reduced from 199 to 84 and closed. There are more than 2,000 non-standard enterprises! The multi-directional co-oxidation process upgrade of the proposed cyclopropane project in Shandong Xinjian. Judging from the newly-constructed projects of cyclopropane according to the statistics of Tiantian Chemical Network, the production capacity of propylene oxide will bloom everywhere in the future, with a total of 6.57 million tons.

Take the six key investment projects in Aksu, Xinjiang as an example, including an annual output of 300,000 tons of propylene oxide, 400,000 tons of ethylene glycol, and an annual output of 400,000 tons of PET.��Five key investment projects in the energy and chemical industry, including the deep processing of coal tar in Baicheng County and the annual output of 15,000 tons of cyclohexane in Xinhe County, have extremely low cost advantages in water, electricity, natural gas, and land; enjoy the country’s western development, The core area of the Silk Road Economic Belt, the state-level economic and technological development zone, and the special policy advantages of southern Xinjiang; and the Kuqa Development Zone has formed a “one area” for energy and chemical industry, textile and clothing, agricultural and sideline product processing, equipment manufacturing, building materials metallurgy, and emerging industries. The development pattern of “six parks”, industrial supporting facilities and park infrastructure have been completed and other supporting advantages.

微信扫一扫打赏

微信扫一扫打赏