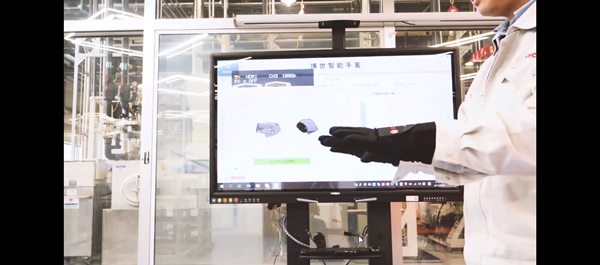

— Thermoplastic Polyurethane from Bosch Smart Glove (TPU ) materials are packaged with various sensors and circuit boards, bringing a super interconnected experience to various industries

— BASF materials and expertise help Bosch improve the production efficiency of smart gloves to meet the growing demand of China’s manufacturing industry.

— BASF at CHINAPLAS 2019: China Import and Export Fair Complex (Guangzhou, China); Booth No.: 11.2A41; Date: May 21-24

April 25, 2019 – Guangzhou, China – BASF provides materials and expertise to Bosch Automotive Components (Suzhou) Co., Ltd. To meet the growing market demand of China’s manufacturing industry. Bosch’s smart glove, made of BASF’s thermoplastic polyurethane (TPU), is a milestone in connected manufacturing, improving operational connectivity and transparency . The product will land on the Chinese market in the second half of 2019.

Bosch smart gloves help companies simplify their processes and improve production efficiency, especially for manual manufacturing and semi-automated manufacturing represented by the automotive industry.

Tony Jones, Head of Industrial Asia Pacific, BASF’s Performance Materials Division, said: “From material procurement, processing technology, to prototype development and mass production, we have worked closely with Bosch to streamline the Bosch smart glove value chain. The simplified business model Helps reduce the overall cost and time-consuming of the Bosch smart glove product development process.”

The cooperation between BASF and Bosch covers the design and development process of Elastollan® TPU membrane processing technology, creating a new The business model simplifies the development process of Bosch smart gloves and shortens the time to market. The technology enables the packaging of delicate sensors and flexible printed circuit boards into the glove.

Functional gloves need frequent contact with water, chemicals and dust during industrial production. BASF’s Elastollan TPU material has excellent mechanical strength, water and chemical resistance, and is the best choice for innovative raw materials for smart gloves. The material’s excellent durability and flexibility can also provide users with a long-term comfortable experience.

Andy Postlethwaite, Global Senior Vice President of BASF’s Performance Materials Asia Pacific Region, said: “Our cooperation with Bosch demonstrates the company’s expertise and competitiveness beyond the field of material innovation, and reflects the company’s commitment to transcend raw materials. The relentless pursuit of supplier identity positioning. We can provide customers with innovative product ideas, such as high-performance material solutions, production processes or business models, etc.”

Shi smart gloves are equipped with high-sensitivity sensors, which can realize real-time simulation of hand movements and greatly shorten the labor training time. In addition, the product can also help users learn the correct assembly steps and record the production process. Product data can be transferred to a computer or smartphone via Bluetooth and compared with stored motion patterns.

微信扫一扫打赏

微信扫一扫打赏