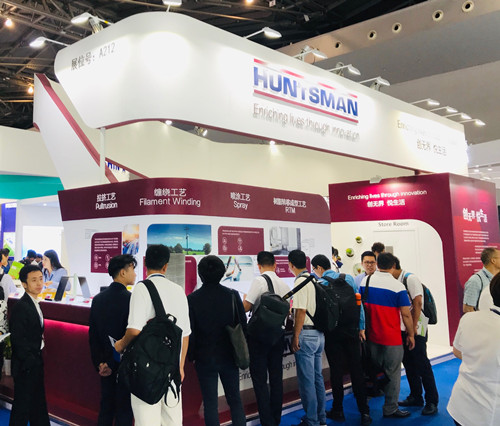

From September 3rd to 5th, 2019, Huntsman Group, the world’s leading specialty chemicals company, made a wonderful appearance with its red and white streamlined design Booth A212, Hall 1, 25th China International Composites Industry Technology Exhibition. This time, Huntsman will focus on displaying the four major processes in the field of polyurethane composite materials, as well as energy-saving and efficient polyurethane composite full-broken bridge system doors and windows. Through years of accumulation, Huntsman has attracted more and more attention from the industry for its mature technology and its potential value.

Huntsman’s streamlined on-site booth

Huntsman has been involved in the field of composite materials for a long time. In addition to the excellent and stable mechanical and thermal properties of the composite materials produced based on two-component polyurethane resin, it is worth mentioning that the VOC emission is almost is 0. At the same time, Huntsman’s four mature process systems: pultrusion process, RTM (resin transfer molding) and high-pressure RTM process, winding process and spraying process, not only the process is stable, but also the product characteristics of polyurethane have been fully utilized. Save costs for customers, and “emerge” in many fields of industrial life such as door and window profiles, sports equipment, automotive structural parts, power poles and towers, and wind power generation.

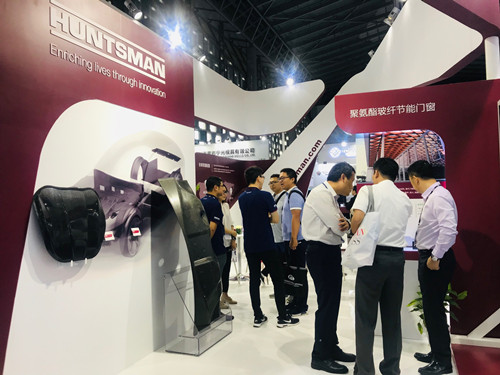

On-site display of door and window profiles, automotive structural parts and other application exhibits

As the highlight product of this exhibition, the doors and windows of the polyurethane composite full-broken bridge system jointly launched by Huntsman and its partners attracted the attention of a large number of visitors. The doors and windows of the polyurethane composite full broken bridge system use lightweight and high-strength polyurethane composite materials, and use resource and energy-friendly materials. According to estimates, if all the doors and windows of existing buildings and new buildings that need to be renovated in China are replaced with polyurethane energy-saving door and window systems of European standards, 420 million tons of standard coal can be saved every year, which is equivalent to 20% of China’s total annual coal. Vigorously promote energy conservation and emission reduction, practice Huntsman’s four sustainable innovation concepts, and promote future low-carbon and environmentally friendly life. In addition, this system also has excellent fire performance, with fire-resistant glass and hardware accessories, the entire window can be fire-resistant for up to 1 hour. Therefore, since entering the market, this system of doors and windows has been widely praised by the industry.

Focusing on sustainable development issues has always been an inexhaustible driving force for Huntsman’s innovation. Su Bingli, Commercial Director of Huntsman Polyurethane Business Unit in China, said, “Compared with traditional materials, innovative polyurethane composite materials and their own production process have more advantages in terms of sustainability. Huntsman hopes that through innovative Products and technologies not only bring value to local customers, but also provide Chinese consumers with a greener and healthier living environment.” In fact, based on mature polyurethane product technology, Huntsman aims at China’s indoor and outdoor air environment and other issues, Launched four sustainable innovative solutions. Strive to create a safer, healthier and more environmentally friendly living space for Chinese consumers with continuously improved material properties and technical levels.

Huntsman Polyurethane Division has always maintained a high degree of concern and continuous investment in the Asia-Pacific region, especially the Chinese market. At present, Huntsman’s high-performance materials have 13 production bases around the world. The Huntsman Asia-Pacific R&D Center in Shanghai has a full set of performance testing and analysis equipment capabilities, including mechanical properties, thermal properties, rheological properties, electrical properties, Tests including reliability performance and application can be implemented. Based on these tests and analyses, Huntsman will provide local customers with custom formulation design and development, and can help customers with injection sample design in the early stage of process layout. In the future, Huntsman will continue to provide local partners with high-quality composite material solutions to meet the growing market demand.

微信扫一扫打赏

微信扫一扫打赏