On July 31, BASF plans to build a new engineering plastics modification unit and a thermoplastic polyurethane (TPU) production device project officially passed the record. This will be the first batch of devices put into production at the Zhanjiang Integrated Base.

The first phase project of BASF’s new integrated production base in Zhanjiang (new construction of engineering plastics and thermoplastic polyurethane and supporting public works), the total investment of the project is 192 million US dollars, all of which are raised by the project unit itself. The project is planned to start construction in April 2020 and be put into operation in 2022.

The project site is located in Donghai Island Petrochemical Industrial Park, Zhanjiang City, Guangdong Province, the southeast corner of BASF Zhanjiang Integrated Project Base. The total area is 220,000 square meters, and the total construction area is 37,713 square meters.

It is reported that the first unit of BASF’s new integrated production base in Zhanjiang is expected to be commissioned in 2022. By then, the new engineering plastic modification unit will contribute 60,000 tons of modified engineering plastic products to BASF in China every year. This will bring BASF’s total annual production capacity of modified engineering plastics in the Asia-Pacific region to 290,000 tons. BASF will fully implement the concept of intelligent manufacturing based on cutting-edge technology at the new integrated base in Zhanjiang. The new facility will use various advanced technologies such as automated packaging, high-tech control systems and automatic guided vehicles.

The project consists of main works, storage and transportation works, public works and auxiliary and environmental protection facilities. The main project includes engineering plastics workshop and thermoplastic polyurethane (TPU) workshop. Construction of engineering plastics in stages, with a total scale of 160,000 tons/year, current production capacity of 80,000 tons/year, and long-term production capacity of 80,000 tons/year; TPU The first phase of construction is completed, with a scale of 32,000 tons/year.

According to Nanfang Daily, on July 30, Ma Xingrui, Governor of Guangdong Province, met with Brudermüller, Chairman of the Executive Board and Chief Technology Officer of BASF Europe, in Guangzhou.

Ma Xingrui emphasized that the BASF new integrated base project in Zhanjiang is a major strategic project with overall significance, and it is an important measure for our province to accelerate high-quality development, form a new pattern of comprehensive opening up, and accelerate regional coordinated development. As a provincial sub-central city in the west wing of the coastal economic belt, Zhanjiang has outstanding location and development advantages, and is striving to build a world-class port-side heavy chemical industry base. Guangdong is confident to work with BASF to build this project into a model for the opening up of my country’s petrochemical industry. It is hoped that the two sides will strengthen communication and docking to ensure that the project starts on time and goes into production as soon as possible.

Brudermüller expressed his gratitude to the Guangdong Provincial Party Committee and the Provincial Government for their great attention and strong support for the BASF project. Guangdong has a good business environment, and policies such as the “Ten Measures for Foreign Investment” have been fruitful. BASF will work with Guangdong Province and Zhanjiang City to actively promote new progress in project construction.

BASF Zhanjiang new integrated production base (Verbund) project introduction

On July 9, 2018, under the joint witness of the Chinese and German prime ministers, Dr. Brudermüller, Chairman of the Executive Board of BASF Europe, and Lin Shaochun, Executive Vice Governor of Guangdong Province, signed the establishment of a highly integrated (Verbund) in Berlin, Germany. Non-binding memorandum of understanding on cooperation in chemical production bases.

It is reported that the Guangdong Integrated Base will be BASF’s largest investment project so far and will be independently operated by BASF. The entire project will be completed around 2030, and the total project investment is expected to reach 10 billion US dollars. The first installations will be completed by 2026 at the latest.

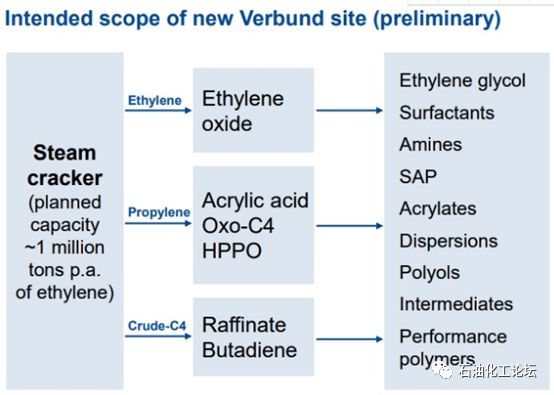

Phase 1 of the project includes petrochemical plants as the core of a well-established Verbund system. A steam cracker with a planned annual production capacity of 1 million tons of ethylene will serve as the beginning of the value chain of the new integrated base. In the subsequent stage, multiple sets of downstream devices will be established to provide more customer-oriented products and solutions for the transportation and consumer goods industries. After the project is completed, it will become BASF’s third largest integrated production base in the world after Ludwigshafen, Germany and Antwerp, Belgium.

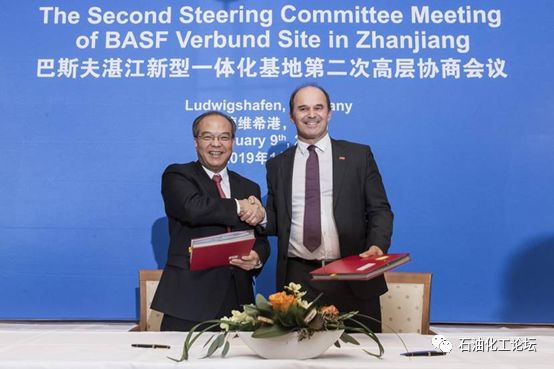

On January 10, 2019, Martin Brudermüller, Chairman of the Executive Board of BASF Europe, and Lin Shaochun, member of the Standing Committee of the Guangdong Provincial Party Committee and Executive Vice Governor, signed a framework agreement in Ludwigshafen, further clarifying the establishment of BASF in Guangdong, China. Planning details of Verbund base.

According to this framework agreement, the new Zhanjiang integrated base will fundamentally apply the concept of circular economy and provide support to customers in South China with sustainable production methods. In an integrated site, waste and by-products from one plant can be used as raw materials for another plant. one based onSmart production concepts with advanced technologies are in the works, aiming to maximize resource and energy efficiency and reduce environmental impact. The project will cover an area of approximately 9 square kilometers.

微信扫一扫打赏

微信扫一扫打赏