Formaldehyde is known to be dangerous and a major cause of many diseases. Most of the formaldehyde in interior decoration comes from the glue in wood-based panels. All kinds of wood-based panels, including plywood, are widely used, such as floors, cabinets, bookcases, decorative panels, etc. If the aldehyde-containing glue can be replaced by aldehyde-free polyurethane adhesive, the indoor environment will have a qualitative leap.

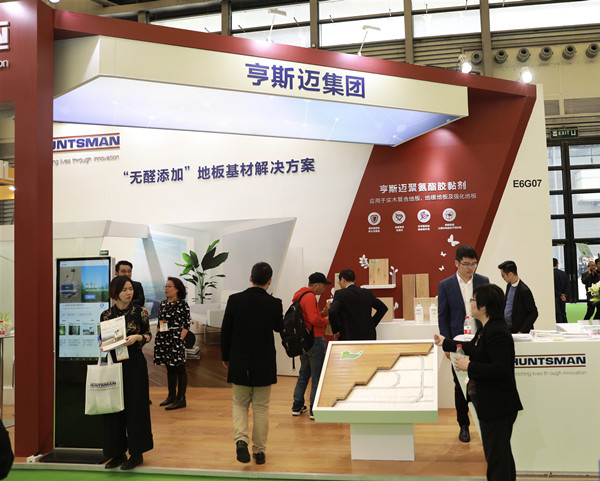

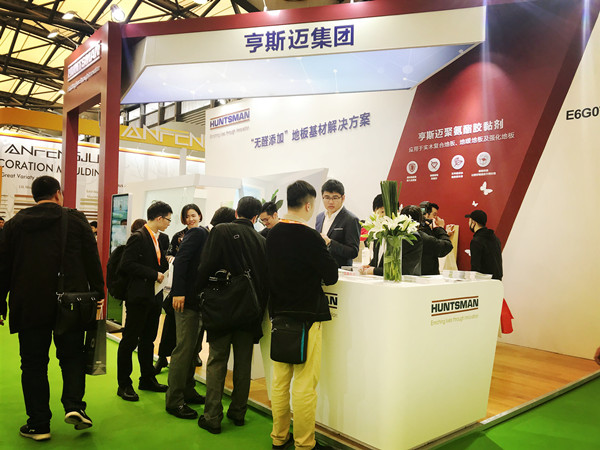

At the site of the 21st China International Floor Materials and Paving Technology Exhibition held from March 26 to 28, 2019, Huntsman, the world’s leading specialty chemicals company, demonstrated the “formaldehyde-free” solid wood Laminate flooring substrate solutions. The reporter from Tiantian Chemical Network interviewed Ms. Liu Xuehong, General Manager of Composite Wood Products Asia Pacific of Huntsman Polyurethane Division, and Mr. Cai Jieyan, Account Manager of Huntsman Polyurethane Division.

Q: Huntsman, as a global manufacturer and sales company of special and specialty chemicals, is more active in chemical exhibitions, so participate in Domotex Asia/DACF (China International Floor Materials and Pavement Technology Exhibition) What is the consideration?

A: This is the second time for Huntsman to participate in Domotex Asia/DACF. Before, Huntsman usually participated in more chemical exhibitions, but later changed its mind and participated in flooring exhibitions. Because we find that the application and promoters of new technologies are often end customers, and they have needs in this regard.

The advantages of our products are performance and aldehyde-free, and these two requirements are generally more concerned by consumers. The downstream customers we directly connect with are generally plate manufacturers, and they may pay more attention to cost. The core value of our products is reflected in excellent performances such as health and environmental protection, which are often more concerned by end customers such as flooring companies and furniture companies.

We want end customers to know more about Huntsman products. Last year was the first time to participate. Over the past two years, it has achieved certain results, and end customers are becoming more and more familiar with the Huntsman brand. They may know the supplier of the board better before, and now they also know the brand of glue. We hope to operate our chemicals with the idea of brand operation, so that more consumers are familiar with Huntsman.

Q: Polyurethane is known as the fifth largest plastic and has a wide range of applications, including upholstered furniture, automotive interiors, refrigerators and freezers, etc. Compared with these industries, its application in the wood products industry started relatively late. So what kind of development has polyurethane aldehyde-free adhesives experienced? At present, what is the consumer’s attention to the product?

A: Now mass consumers may not know much about polyurethane. It is generally believed that polyurethane is a chemical product, but in fact it is the chemical product closest to consumers. With the improvement of people’s living standard and social development level, the development of polyurethane industry and its downstream application fields are becoming more and more extensive.

Perhaps 10 years ago, everyone didn’t know that wood-based panels had an environmental protection requirement. They only knew that smelly panels were not good. With the improvement of living standards, people’s awareness of protecting themselves and their families’ health and environmental protection is becoming stronger and stronger, and people will pay more and more attention to formaldehyde-free products—or products with less formaldehyde.

Liu Xuehong, General Manager of Composite Wood Products Asia Pacific, Huntsman Polyurethane Division

Q: Compared with the “formaldehyde-free” flooring solution launched by Huntsman, what advantages does it have?

A: For solid wood flooring, due to its high price and certain pickiness about installation and geothermal environment, most consumers are discouraged from it. Solid wood composite flooring has obvious advantages in price, but aldehyde-containing adhesives such as urea-formaldehyde glue and phenolic glue commonly used in solid wood composite flooring have the hidden danger of “excessive formaldehyde release”, especially in geothermal environments, formaldehyde will accelerate from the floor. , causing adverse effects on the occupants.

The “formaldehyde-free” polyurethane glue launched by Huntsman chemically reacts with the moisture in the wood when the veneer is bonded, and this chemical reaction is irreversible, so it will not release formaldehyde. It can provide a high-quality green home environment for sensitive groups such as children, pregnant women, the elderly, and high-end groups who pursue quality of life.

In addition, in addition to being environmentally friendly and healthy, formaldehyde-free adhesives can make the structure of wood stronger and have excellent moisture resistance. Huntsman’s “formaldehyde-free” solid wood composite flooring substrate can adapt to the geothermal environment of bathrooms, kitchens, etc.

Q: Just now you mentioned “environmental protection requirements for wood-based panels”. In addition to the standards currently implemented by the country, “interior decoration materials, wood-based panels and theirFormaldehyde Release Limits in Products”, and “Technical Requirements for Solid Wood Flooring for Floor Heating”, etc. Huntsman’s four innovative solutions for sustainable development are tailor-made for China, so what localization measures does Huntsman have for China’s national standards in flooring solutions?

A: Huntsman participated in the formulation of floor heating standards, and we were one of the drafting units. The floor heating floor standard just introduced in 2018 stipulates that the formaldehyde emission must be less than 0.06 mg, while the formaldehyde emission of the floor heating floor made of Huntsman formaldehyde-free polyurethane glue is 0.02 mg. If the traditional glue is used for floor heating panels, the volatilization of formaldehyde will be accelerated, but if the polyurethane glue without aldehyde is used, this situation will not happen.

It should be noted that when considering the amount of formaldehyde released, the carrying capacity of the space must be taken into account. If there are too many plates in a certain space, the amount of formaldehyde released will also exceed the standard. In the formaldehyde emission standard pyramid, it is clearly stated that although E1, E0 and super E0 have reached the environmental protection board standard, they need to be used in a limited amount; the above F4 and NAF star to formaldehyde-free are used in unlimited quantities because of their formaldehyde emission. has reached a very small value.

In addition, we also hope to respond to the recommendations of the National Flooring Committee and strive to achieve “floor to wall”, that is, to use formaldehyde-free glue in decorative panels. This requires a breakthrough in the craftsmanship of parquet. Once realized, it will be a “whole house formaldehyde-free solution”.

Jieyan Cai, Account Manager of Huntsman Polyurethane Business Unit

Q: At present, what is the market’s acceptance of “formaldehyde-free” polyurethane adhesives?

A: In fact, “formaldehyde-free” polyurethane adhesives have entered the Chinese market for more than 10 years, but the market has really entered an explosive period, that is, the past two or three years.

The market does need a long acceptance process. First of all, the cost and price of the product itself will be relatively high; secondly, it will be transmitted to the production enterprises, those traditional old equipment cannot use this kind of glue to make plates, so the industry is doing a technology update and equipment update; finally , and then transmitted to the end consumers.

Now this product is relatively mature. Sophia Custom Furniture specifically mentioned in the 2018 annual report that this year, Kangchun board will be fully promoted, and the glue in it is “formaldehyde-free” polyurethane glue. Such a decision by an industry leader is also based on the maturity of the market and the needs of consumers. Therefore, the industry believes that the next 2-3 years will be the outbreak period of formaldehyde-free panels.

微信扫一扫打赏

微信扫一扫打赏