As an important class of chemical products, linear alcohols play an important role in the fields of food, pharmaceutical chemicals, cosmetics, surfactants, plasticizers and lubricants. The traditional synthesis method is to undergo a hydroformylation reaction of olefins to produce aldehydes, and then undergo a reduction reaction to produce alcohols with one more carbon. One-step reductive hydroformylation of olefins is an ideal way to synthesize linear high-carbon alcohols, which simplifies the operation process and reduces energy consumption and waste emissions. However, the catalysts that have been developed focus on homogeneous precious metal catalyst systems. The reaction activity and linear alcohol selectivity are not ideal, and the separation and recycling of the catalyst are difficult.

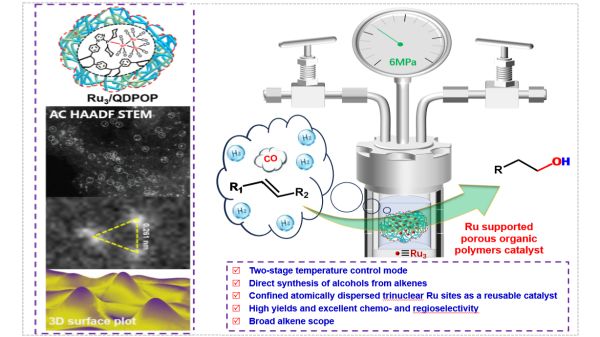

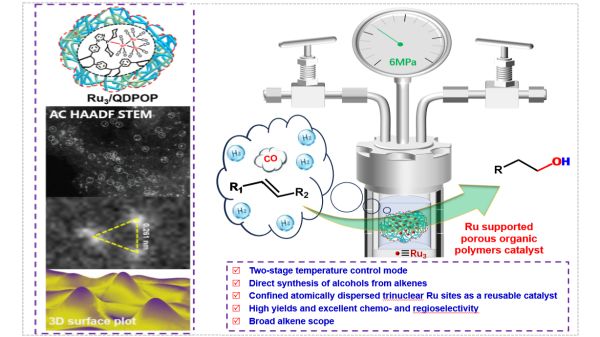

Recently, a low-carbon catalytic conversion research group led by Yang Yong, a researcher at the Catalytic Polymerization and Engineering Research Center of the Qingdao Institute of Bioenergy and Processes, Chinese Academy of Sciences, designed and synthesized a phosphine-containing organic polymer-based triphosphate with a clear structure. The core Ru site heterogeneous catalyst developed a second-order programmed temperature control strategy and realized the “one-pot” reductive hydroformylation reaction of olefins to directly synthesize linear alcohols. This catalyst shows reactivity, chemical and regional selectivity comparable to that of homogeneous catalysts. It is suitable for C3-C12 different carbon chain olefins, cyclic olefins and aromatic olefins. It has good stability and is easy to separate and recycle. The advantage of this strategy is that the low-temperature hydroformylation reaction in the first stage can effectively reduce the occurrence of olefin isomerization and hydrogenation side reactions during the reaction process, maximize the conversion of olefins into linear aldehydes, and provide a high-efficiency and high-efficiency second stage. The selective hydrogenation reaction provides guarantee for the preparation of linear alcohols. Under optimal reaction conditions, the conversion rate of 1-hexene in the model reaction is nearly 100%, the selectivity of heptanol reaches 95%, and the ratio of linear/branched alcohols reaches 30. This result is of great significance for the development of catalysts and processes from olefins to linear higher carbon alcohols.

Based on the phosphine-containing organic polymer-based trinuclear Ru site heterogeneous catalyst olefin “one-pot method” “Direct preparation of linear alcohols by reductive hydroformylation

As we all know, in January 2020, the country issued an upgraded version of the “Plastic Ban Order”, requiring that the production of some plastic products be banned and restricted starting in 2025. , sale and use. However, in the past two years, as public opinion about the “plastic ban” has declined, the domestic market has rebounded from traditional plastic product consumption habits, and the promotion of degradable products has weakened. In response to this phenomenon, Zheng Yueming suggested strengthening the implementation and supervision of the “plastic ban order” and prohibiting traditional plastics from entering the end consumption areas where plastic bans are prohibited. We will consolidate the territorial responsibilities of local governments and use the effectiveness of the “plastic ban” as an evaluation indicator for selecting civilized cities, hygienic cities, and tourist cities. Further improve the degradable product standard system, strengthen product quality testing certification and labeling management, and promote the healthy development of the market.

微信扫一扫打赏

微信扫一扫打赏