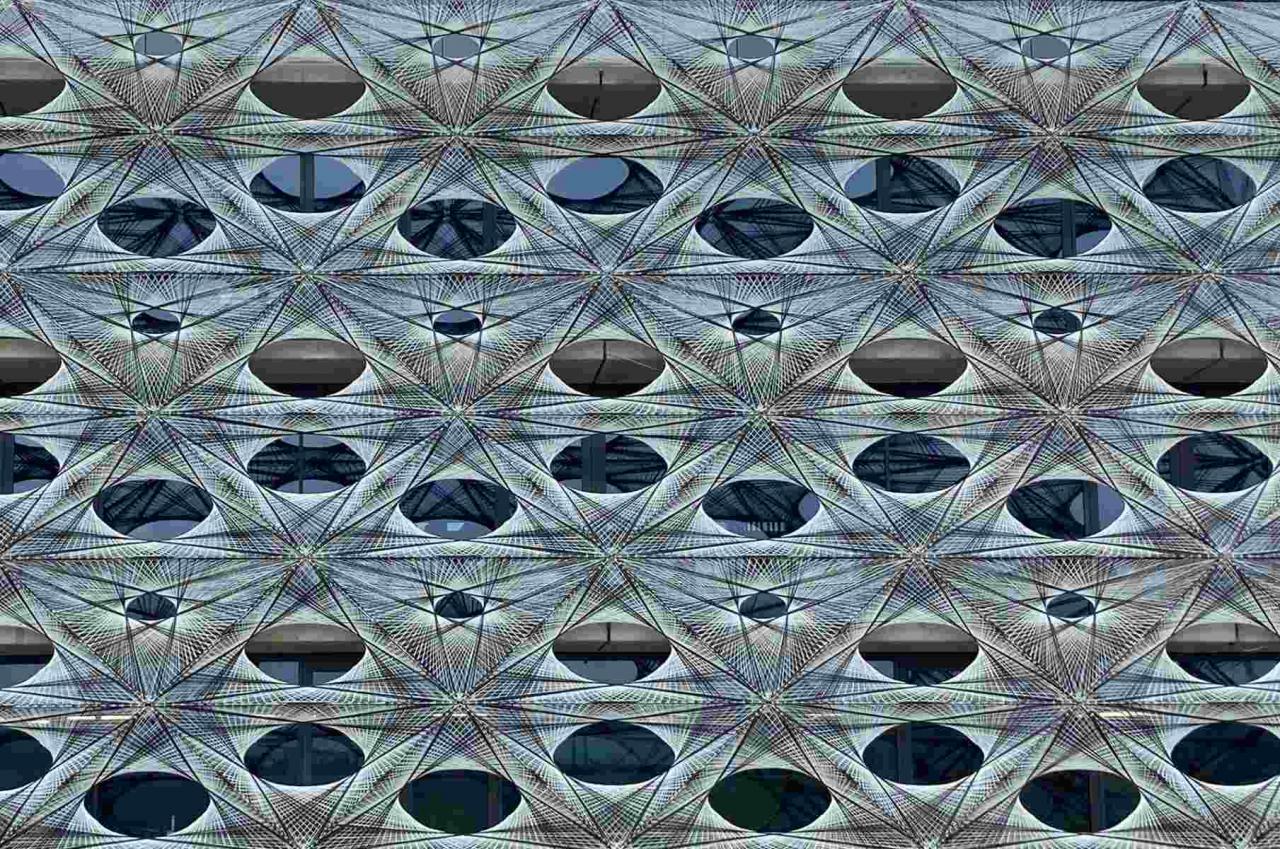

With the Texoversum building, Reutlingen University has built a training and innovation center for the textile industry that is unique in Europe. The nearly 2,000-square-meter textile facade of the new building is also causing a stir architecturally: it combines the innovative capabilities of the textile industry with Reutlingen’s 160-year-old textile tradition. The highlight is that the parts are wound from fibers and held in place with a special plastic resin.

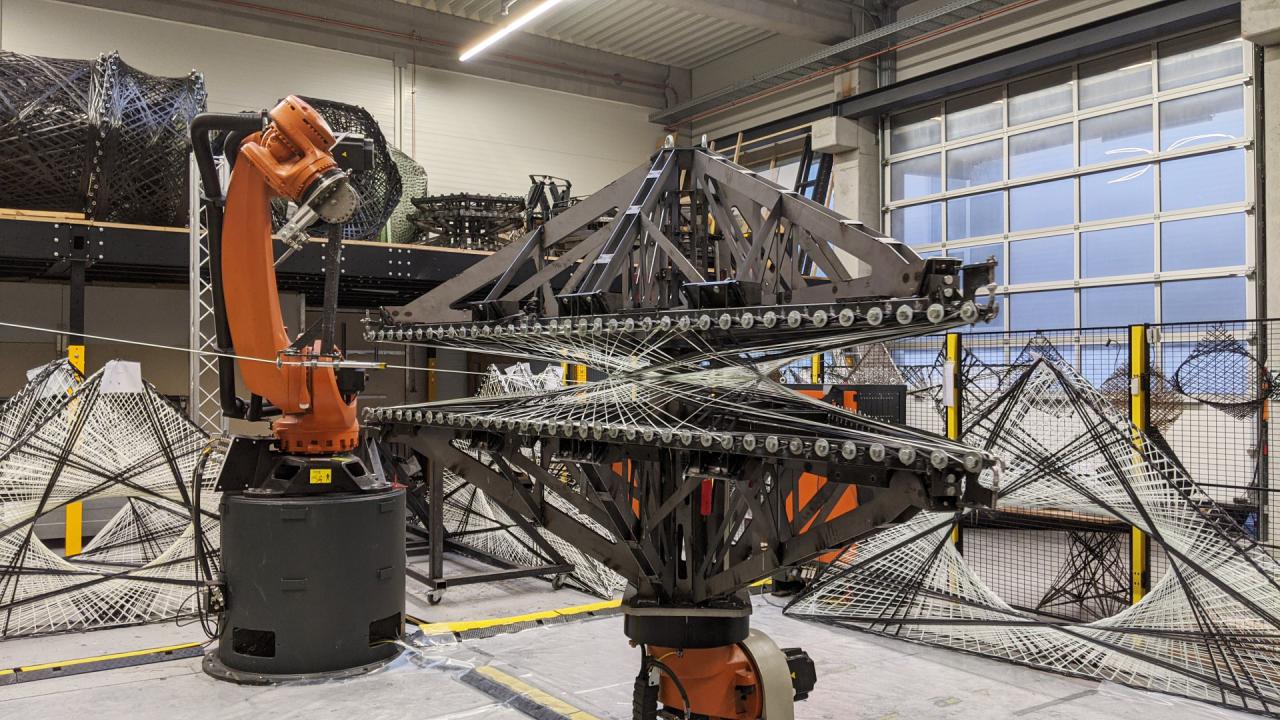

The façade of the Texoversum building is just one example of a new technology that will revolutionize the construction industry. The complex structure was designed on a computer and is based on robotically wound carbon fiber. The fibrous structure, which resembles networks in nature, such as those found in spider webs, beetle wings or palm leaves, is extremely lightweight but at the same time highly elastic and requires very little material. This not only saves resources, but also facilitates the transportation and assembly of components.

The co-inventor of this innovative technology is the architect Prof. Moritz Dörstelmann, whose company FibR was also involved in realizing the exterior of the Texoversum building: “Compared to conventional steel and concrete structures, we were able to use a minimum of materials, Because the robot only processes the fibers that are required for the corresponding structural strength. As a result, we also reduce CO2 emissions considerably”. Professor Moritz Dörstelmann also believes that the technology also has advantages in terms of roof structure, support and interior finishing.

The strength and durability required for this composite is provided by Desmocomp®, an aliphatic polyurethane resin system from Covestro, where the fibers appear to be embedded in the matrix. “The resin is very resistant to weathering and the sun’s high-energy UV radiation, making it ideal for outdoor applications,” explains Pejman Norastehfar, an architect and construction application specialist at Covestro’s Coatings and Adhesives division. Other advantages include its excellent chemical resistance and flame retardancy.

In the Texoversum building, the textile façade fulfills several important functions at the same time: it gives the building a unique appearance and stabilizes the surrounding balconies. It also acts as a railing and provides the necessary sunshade for the glass facade behind.

With an interior area of approximately 3,000 square meters, the building is used as workshops, laboratories, textile collections, think tank spaces and classrooms. Construction costs for the Texoversum building amounted to 18.5 million euros and were provided by the Südwesttextil employers’ association, whose members include the company FibR in Kernen, east of Stuttgart.

微信扫一扫打赏

微信扫一扫打赏