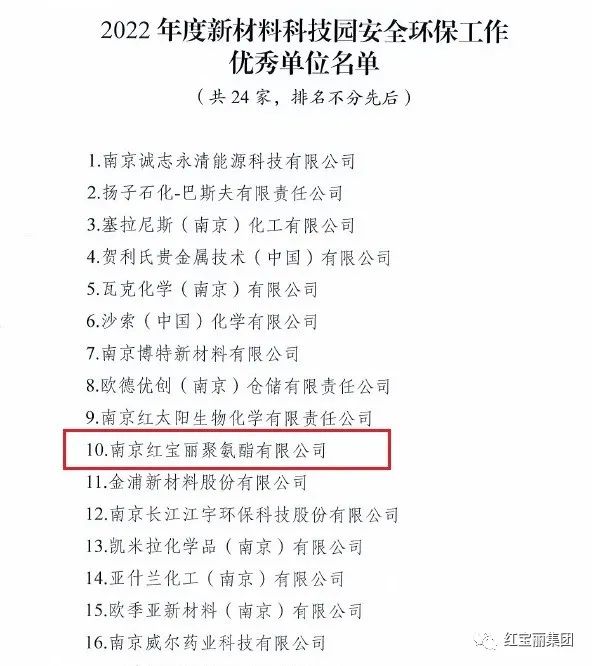

Recently, Nanjing Hongbaoli Polyurethane Co., Ltd. won the title of “2022 New Material Science and Technology Park Safety and Environmental Protection Excellent Unit” in Nanjing Jiangbei New District. Another honor after the unit”.

For a long time, Hongbaoli Polyurethane Company has insisted on “two-handed and two-handed” safety production and ecological environmental protection, giving full play to the functions and responsibilities of personnel at all levels, and taking multi-channels to improve ideological understanding, multi-faceted expansion of work carriers, and multi-level practical behavior construction as improvements. The strong grasp of safety and environmental protection management capabilities has established an effective long-term mechanism for safety and environmental protection work, and realized long-term safe and green operation of the device.

Last year, Hongbaoli Polyurethane Co., Ltd. centered on on-site management, actively carried out technical upgrading and transformation and hidden danger investigation and treatment, effectively built a safe production line of defense, made every effort to improve the level of environmental governance, and accelerated the implementation of green and clean production, and achieved a series of remarkable results.

Outcome One

In the polymerization section, the capacity of DCS has been expanded, the batch production function has been added, and the alarm handling module has been updated. Currently, more than 30 recipes have been successfully run, further improving the response speed and safety.

Result 2

Strengthen the management of operation links, implement centralized fire control, use the five-in-one information intelligent platform to manage the entire process, formulate strict safety measures, and strictly enforce operating procedures to ensure construction safety to the greatest extent.

Result three

Comprehensively sort out the sewage pipe network and monitoring system in the factory area, realize remote control of rain and sewage switching, implement automatic transformation of slag discharge and slag washing devices, strengthen the reuse of condensed water, and achieve “source reduction and internal reuse”.

Outcome Four

Carry out HAZOP analysis on schedule, update safety response risk assessment content, provide basis for process safety optimization and development, continuously improve internal control mechanism, and improve intrinsic safety level.

Safety and environmental protection is an important prerequisite and basic guarantee for the high-quality development of an enterprise. All employees of the polyurethane company always adhere to this concept, implement government decisions as always, work together, make persistent efforts, coordinate safety production and ecological environmental protection, and effectively consolidate good development We will strive to promote the implementation of high-quality development.

微信扫一扫打赏

微信扫一扫打赏