Xinhua News Agency, Beijing, August 3rd The State Council issued the “National Fitness Plan (2021-2025)” (hereinafter referred to as the “Plan”) ), and make arrangements for promoting the development of national fitness at a higher level in the future and better meeting the fitness and health needs of the people.

(data map, issued by Xinhua News Agency)

The “Plan” points out that under the strong leadership of the Party Central Committee and the State Council , my country’s national fitness-for-all strategy has been implemented in depth, the level of public fitness services for all has been significantly improved, fitness venues and facilities for all are gradually increasing, and people’s enthusiasm for promoting health through fitness is increasing. Healthy China and the construction of a sports power have taken new steps.

The “Plan” clearly states that by 2025, the national fitness public service The system is more perfect, the people’s physical fitness is more convenient, the enthusiasm for fitness is further improved, the number of participants in various sports events continues to increase, and the proportion of people who regularly participate in physical exercise reaches 38.5%. ) Three-level public fitness facilities and community 15-minute fitness circles will be fully covered, driving the total size of the national sports industry to 5 trillion yuan.

However, in contrast to this plan, the current penetration rate of the domestic fitness equipment industry is low. In the past ten years, despite the influence of domestic sports industry policy incentives, changes in consumer concepts, and the improvement of the production and R&D capabilities of fitness equipment companies, coupled with the promotion of the development of the international fitness equipment industry, the overall domestic fitness equipment market has maintained a growth trend. However, the penetration rate of fitness equipment in my country is low. There are only 4 sets of fitness equipment per 100 urban households in my country, and the penetration rate is less than 5%, which is far lower than the 28% fitness equipment penetration rate in European and American countries. The development potential is considerable.

Common fitness equipment in our daily life can be divided into single-function according to the number of training functions and comprehensive multi-function two categories. Among them, there are more types of single-function equipment, which are more in line with the needs of the public for daily fitness. This type of fitness equipment includes: treadmills, dumbbells, and multi-functional sit-up boards.

In terms of selection of fitness materials, comfort, Safety and environmental protection are the primary indicators for consumers to choose sports and fitness equipment, so various high-performance, multi-functional foam materials are favored. Among all kinds of foam materials, polyurethane foam materials have to be mentioned.

Polyurethane foam material, namely PU foam, is high quality and low price The traditional foam material has the characteristics of ultra-low temperature thermal conductivity, high efficiency and energy saving, heat-resistant heat preservation, high-efficiency insulation, and sound insulation. There are two types of soft foam and hard foam. Soft foam has an open-cell structure, while hard foam has a closed-cell structure. Soft foam is divided into two types: crusted and non-skinned. Polyurethane (foaming material) has been compounded by major manufacturers with higher performance in recent years. For the sports and leisure industries, it can provide personalized production coatings, adhesives, thermoplastic polyurethanes, polycarbonates, foams, films, elastomers, etc. Specialty raw materials needed to provide solutions for applications such as footwear, sports equipment, goggles and wearables, functional textiles and artificial leather. Thanks to its high mechanical strength, flexibility and oxidation resistance, high-performance polyurethane (foaming material) is widely used in the fields of synthetic leather, rubber and material fiber sports protective products.

- ETPU

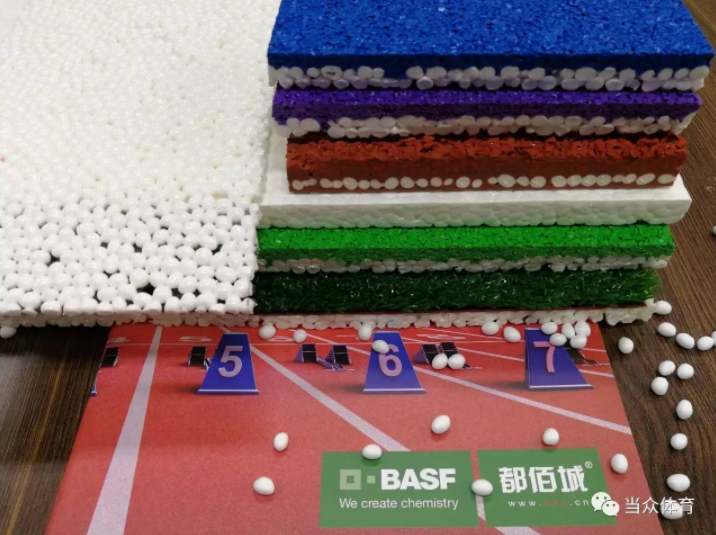

Thermoplastic polyurethane foam material, namely ETPU, is made of thermoplastic polyurethane It is a new type of polymer material composed of countless independent small pores of TPU foam with full elasticity and light weight. Non-toxic, tasteless, degradable, and more environmentally friendly; it has excellent resilience, can adapt to various temperatures, and has a more gentle and comfortable touch; compared with traditional rubber and plastics, ETPU has excellent aging resistance and weather resistance. Thereby, the service life of sporting goods can be greatly extended. ETPU can be used wherever customers require a combination of low weight, excellent mechanical properties and good durability over a wide temperature range, such as in the sports sector or in logistical technology applications. ETPU can be widely used in sports shoes, buffer gaskets, plastic track, sports �Factory floors, bicycle cushions, water and underwater sports equipment, bicycle inner tubes and interior decoration.

- Judo / Sanda / Wushu / Taekwondo pads

Judo, Sanda, Wushu and Taekwondo and other sports need to use pads to cushion possible injuries to the body during the competition. The core layer of this type of pad is a high-quality polyurethane foam , The coating is made of polyvinyl chloride foam material. The above materials can provide excellent shock absorption and anti-slip capabilities to increase the body protection of athletes or students, and meet the requirements of IJF. In addition, polyurethane foam materials can also be used in protective gear and teaching aids such as helmets and kick targets for such sports.

- bicycle seat

Resilient pads made of foamed thermoplastic polyurethane (ETPU) can Provides perfect comfort for the hips and enough lateral support during movement. From the appearance, it also gives people a simple and atmospheric feeling. After years of research and development experiments, GreenMobil developed Popcorn®|ETPU ® polyurethane foam material, and the bicycle seat cushion formed by steam molding process can solve all problems. Popcorn®|ETPU®polyurethane foam material bicycle seat cushion is molded at one time, easy to clean, impervious to water, resistant to hydrolysis, high resilience, and easy to process.

- Treadmill board

Keep, a unicorn in the field of technological sports, recently launched a The revolutionary new treadmill K2 in the fitness industry uses BASF’s Infinergy® thermoplastic polyurethane foam (ETPU) as the key technical support for its energy rebound running board. With the excellent elasticity, shock absorption and high resilience performance of Inafine™, the new generation of intelligent treadmill K2 can bring unparalleled experience to indoor runners. Its running deck absorbs and returns energy to minimize the impact and damage to joints while running on a treadmill. In addition, the strong damping performance of ETPU material can bring users a quieter running experience, and they can enjoy the fun of running in the apartment at any time without disturbing the neighbors.

- football

2018 World Cup official game ball – Telstar 18 (TV Star), there are four layers in total, the innermost layer of the ball skin is an adhesive coating layer, which bonds the textile base layer to the layer above, and on top is a layer of polyurethane foam material, about one millimeter thick, made of millions of Composed of gas-filled microspheres. This polyurethane foam material has a high degree of elasticity, allowing the ball to return to its original shape immediately after being deformed by kicking to ensure the best flight trajectory. The outer layer consists of two dense layers of polyurethane of different densities, which make the ball highly elastic and resistant to wear.

微信扫一扫打赏

微信扫一扫打赏