E-bike manufacturerIsoco Bikes (Saalfeld, Germany) and plastic manufacturing company V

frames (Schmiedfeld, Germany) has signed an exclusive agreement with the Lehoss Group (Hamburg, Germany) to introduce high-performance fiber-reinforced composites, including long carbon fibers and biopolymer carbon fiber composites, for bicycle frames and parts production.

According to the agreement, V

Frames expects to mass-produce injection-molded carbon fiber composite frames, forks and other components for several OEMs by 2027, with the goal of producing 1 million components at Isoco’s factory in Schmidfeld, Thuringia. Following this, the main focus was on improving the properties of the raw materials to achieve lighter, more impact-resistant future frames with up to 50,000

Long-term modulus of elasticity in MPa (compared to the current 32000 MPa), further improving stiffness.

According to the Life Cycle Analysis (LCA) conducted by the University of Linz, Austria, V

Frames claims it has produced some of the most sustainable bike frames on the market, with a 64% reduction in carbon footprint compared to traditional aluminum frame production.

V

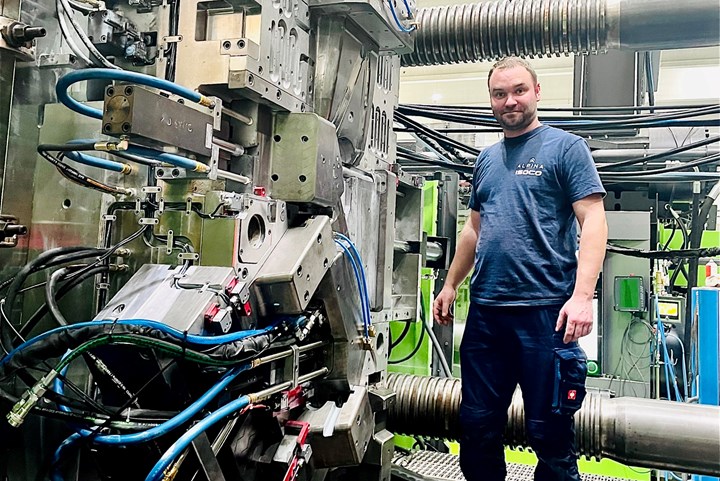

Frames and Lehvos focus on using recycled fiber compounds from different industries for new frames, which are then 100% recycled into new bicycle component products at the end of their product life, thus providing full circularity. The production site is located in Germany, and Isoco’s current production capacity is about 3 million units per year.

V Frames managing director Michael Müller said:

“Lehvos is an excellent partner for the development, production and testing of high-performance materials. Through these steps, we can push the limits of technology to new levels. For example, Buddy Electric/Isoco

The X1 frame passed the drop quality test at 23kg at a drop height of 1120mm, a level that far exceeds the highest test requirements of any agency and is unattainable for most aluminum and traditional carbon fiber frames. ”

Michael

The materials used for these high-performance frames are now available to third parties, according to Müller. Other materials are currently being developed and tested, such as what is believed to be the world’s first bio-based long carbon fiber material for water-assisted injection molding technology (WIT).

Müller continues: “Together we are also now also pushing the limits of environmental sustainability with carbon fiber reinforced bio-based polyamides. We are excited to present new materials in frames and components in the coming months and years.” performance outcomes. V

Frames offers the perfect material for frames or components of any geometry, to be tailored. ”

New materials brought to market through this collaboration include:

Bio-based long carbon fiber materials for water-assisted injection molding technology (WIT).

Bio-based polyamide (PA) reinforced with short carbon fibers.

Economical, ecological and performance-optimized materials based on polyamide, carbon fiber and glass fiber compounds.

微信扫一扫打赏

微信扫一扫打赏